a320 aircraft characteristics airport and maintenance planning ac

a320 aircraft characteristics airport and maintenance planning ac

recommended ACN/PCN system in 1983. For questions regarding the LCN system contact Airbus. ACN/PCN Reporting System: Section 07-09-00 provides ACN data

A319/A320/A321 Flightdeck and systems briefingfor pilots

A319/A320/A321 Flightdeck and systems briefingfor pilots

IT MUST NOT BE USED AS AN OFFICIAL REFERENCE. FOR TECHNICAL DATA OR OPERATIONAL PROCEDURES. PLEASE REFER TO THE. RELEVANT AIRBUS DOCUMENTATION. Issue September

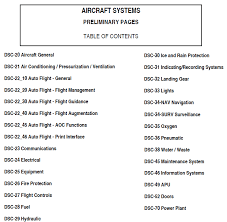

AIRCRAFT SYSTEMS

AIRCRAFT SYSTEMS

15 Feb 2013 RJA A318/A319/A320/A321 FLEET. DSC-25-10-100 P 2/2. FCOM. 07 APR 11. Page 33. A318/A319/A320/A321. FLIGHT CREW. OPERATING MANUAL. AIRCRAFT ...

@AIRBUS

@AIRBUS

To ensure this true market leadership Airbus continues to invest in improvements in the A320 For questions regarding the LCN system

Taxiway Overflight Air Canada Flight 759 Airbus A320-211 C-FKCK

Taxiway Overflight Air Canada Flight 759 Airbus A320-211 C-FKCK

25 July 2018 Safety issues identified in this report include the need for consistent flight management system autotuning capability within an air carrier's ...

Airbus A319/320/321 Notes

Airbus A319/320/321 Notes

5 May 2023 ASM is Aircraft Systems Manual how the systems on the A320 work. FOM is ... American Airlines Airbus A319

Airbus

Airbus

On the green & yellow systems the normal source of pressure is the Engine Driven Pump (EDP) and the auxiliary source is the Power Transfer Unit. (PTU). The PTU

Airbus

Airbus

This “manual ROPS” is expected to be proposed on the A320 and A330/A340 families by 2011/2012. The ROPS will be basic on the A350XWB. The extension of the

Airbus

Airbus

In addition to the control inputs the LGCIUs provide the system pa- rameters for the flight deck display and fault annunciation. System re- dundancy is

A319/A320/A321 Flightdeck and systems briefingfor pilots

A319/A320/A321 Flightdeck and systems briefingfor pilots

STL 945.7136/97. AIRBUS. A319/A320/A321. Flightdeck and systems briefingfor pilots. THIS BROCHURE IS PROVIDED. FOR INFORMATION PURPOSES ONLY.

a320 aircraft characteristics airport and maintenance planning ac

a320 aircraft characteristics airport and maintenance planning ac

The content of this document is the property of Airbus. It is supplied in confidence and commercial security on its contents must be maintained.

a320-technical-notes.pdf

a320-technical-notes.pdf

May 28 2019 In the Pack Schematic there is an anti-ice valve in the system. It has nothing to do with engine or wing anti-.

a320-normal-procedures.pdf

a320-normal-procedures.pdf

Feb 15 2022 A discrepancy in Green Dot speed computed by FMGS and TAKEOFF application indicates a difference in TOW used in both systems. 4. Disconnection ...

Airbus

Airbus

Group Manager a318/a319/a320/a321 operational standards Customer services. Radio Altimeter erroneous values. 2. System architecture. All Airbus aircraft

Untitled

Untitled

Jan 31 2000 AIRBUS TRAINING. INDICATING/RECORDING SYSTEMS. 1.31.05. P 1. A320. SIMULATOR. EIS - GENERAL. SEQ 001 REV 36. FLIGHT CREW OPERATING MANUAL.

AIRCRAFT SYSTEMS

AIRCRAFT SYSTEMS

Mar 29 2013 AIRCRAFT SYSTEMS. EQUIPMENT. PRELIMINARY PAGES - TABLE OF CONTENTS. RJA A318/A319/A320/A321 FLEET. DSC-25-PLP-TOC P 1/2.

A320-Electrical.pdf

A320-Electrical.pdf

AIRBUS TRAINING. ELECTRICAL. 1.24.00. P 1. A320. SIMULATOR emergency AC power to the aircraft electrical system if all three main generators fail. This.

Airbus

Airbus

A320 Flight Safety Director & Chief Engineer Advisor. A320 Program. 1 Introduction Safety Confidential Reporting System incident and.

a320 aircraft characteristics airport and maintenance planning ac

a320 aircraft characteristics airport and maintenance planning ac

Mar 1 2022 @AIRBUS. Issue: Sep 30/85. 1. Rev: Mar 01/22. A320 ... FIGURE Ground Service Connections - Oxygen System. May 01/14. Subject 5-4-6.

A320 ʹ Technical Notes

Last Updated 15th Oct 2022

TheAirlinePilots.com

GENERAL

AIRCONDITIONING

PRESSURIZATION

VENTILATION

AUTO FLIGHT

COMMUNICATION

ELT CVRELECTRICAL

FLIGHT CONTROLS

HYDRAULIC SYSTEM

INDICATING / RECORDING SYSTEMS

LANDING GEAR

PNEUMATIC SYSTEM

ENGINES

FUEL SYSTEM

APUOXYGEN

CB PANELS

TRANSPONDER

PREDICTIVE WINDSHEAR

WX RADAR

GPWS TCASNAVIGATION

FIRE PROTECTION

GENERAL

AIR CONDITIONING

In the Pack Schematic there is an anti-ice valve in the system. It has nothing to do with engine or wing anti-

ice. If the Pack outlet temperature is below 0 degrees C, then there is a danger of ice buildup in the ducting

etc. To ensure the temperature is above 0, an anti-ice valve is fitted which can introduce hot bleed air just

downstream of the pack turbine.PRESSURIZATION

VENTILATION

The concept of skin heat exchange (may be oversimplified but it works)Heat is exchanged when warm air from avionics and cold skin of aircraft get in touch. However, the aircraft

skin may not be cold all the time e.g. aircraft on ground parked with OAT of 40oC. Even after departure from

an airport with an OAT of 40 it will take some time for the aircraft skin to get cold. So, under these conditions

there is no point of making warm air contact the skin. Its only when the skin is cold that this phenomenon

would work. So, if the skin is warm, inlet and outlets are open for ventilation (just like doors and windows in

the absence of an air-conditioner). This is the open configuration.Once the skin is cold enough then the inlet and outlet openings are closed and the warm air from avionics

equipment is circulated in a closed circuit to make contact with the cold aircraft skin where heat is exchanged

and the air cools.It is possible that after takeoff the skin is still warm since some time is needed for temperature to drop and

cool the skin. In this case we need an intermediate solution because if we open the outlet completely it will

interfere with the pressurization system. Thus, an intermediate configuration is the answer by opening the

outlet a little bit a bit not fully. Similarly, it is possible that on ground the skin is cold due to low OAT. In this

case the closed-circuit configuration works even on ground.Another way the air can be cooled is by expanding it (if compression heats up then expansion cools). So, in

the closed circuit along with skin heat exchange, the air is directed to the cargo compartment so that it can

expand there (lot of room there to expand). When the objective is achieved i.e. to cool the air, it is redirected

back to avionics equipment as shown in schematics.AUTO FLIGHT

In level flight, if the A/THR is disengaged and thrust set to idle, the aircraft decelerates until the auto-trim

stops. This occurs at a predetermined angle of attack called Alpha Prot. The speed that equates to Alpha Prot

(Va PROT) is displayed as the top of a black and amber strip on the PFD speed scale. If no input is made on

the sidestick, the aircraft will descend to maintain its current AOA (Va PROT). To maintain the flight path, the

pilot must increase the backpressure on the sidestick, which also provides a tactile indication that auto-trim

has stopped. At Va PROT, AOA protection becomes active and, if the sidestick is released to neutral and no

thrust applied, the aircraft will gently descend maintaining Va PROT. When AOA protection is active, the

speed brakes retract automatically, if previously extended, and the bank angle limit is reduced from 67° to

45°.

If the pilot maintains the backpressure, Alpha Floor will activate. If the pilot disconnects the A/THR while

maintaining full back stick, Alpha Max may be reached. The speed which equates to Alpha Max (Va MAX) is

displayed as the top of the red strip on the PFD speed scale. Alpha Max is close to, but short of the 1g stall.

When flying at Va MAX, the pilot can make gentle turns if necessary. In turbulence, airspeed may fall

temporarily below Va MAX without significant effect.With the A/THR engaged, the aircraft will not decelerate below VLS (displayed as top of amber strip) even if

the target speed is selected below VLS.A low energy aural warning is triggered when the aircraft energy level is below a given threshold. This energy

level is a function of several parameters including aircraft configuration, speed, horizontal deceleration rate,

flight path angle and altitude. The aural warning "SPEED, SPEED, SPEED" alerts the pilot of the requirement

to adjust thrust and flight path. It is triggered during deceleration before Alpha Floor (unless Alpha Floor is

triggered by stick deflection). The delay between the aural warning and Alpha Floor activation is a function

of deceleration rate.If Alpha Prot is reached and the pilot still maintains aft sidestick, Alpha Floor protection (set between Alpha

Prot and Alpha Max) will be reached. This protection triggers the application of TOGA thrust and the aircraft

will start to climb at a relatively constant low airspeed. Alpha floor protection is inhibited in some cases.

MODE REVERSION

FAC ʹ Flight Augmentation Computer

COMMUNICATION

AUDIO CONTROL PANEL

Some VORs/NDBs also transmit ATIS information. The 'on voice' button blocks out the ident (beeps) so you

can listen to the voice information. Manchester (MCT) VOR is a case in point.CABIN CALL

ELT CVRELECTRICAL

DIFFERENTIAL PROTECTION:

Generators do experience short circuits and abnormal electrical conditions. In many cases, equipment

damage due to these events can be reduced or prevented by proper generator protection. Generators, unlike

some other power system components, need to be protected not only from short circuits, but also fromabnormal operating conditions. Examples of such abnormal conditions are over-load, over-excitation, over-

voltage, and loss of field, unbalanced currents, reverse power, and abnormal frequency. When subjected to

these conditions, damage or complete failure can occur within seconds, thus requiring automatic detection

and tripping.All faults associated with synchronous generators may be classified as either insulation failures or abnormal

running conditions. An insulation failure in the stator winding will result in an inter-turn fault, a phase fault

or a ground fault, but most commonly the latter since most insulation failures eventually bring the winding

into direct contact with the core. Differential relays, in particular the digital ones are used to detect stator

faults of generators.Differential protection for a generator is mainly employed for the protection of stator windings of generator

against earth faults and phase-to-phase faults. The stator winding faults are very dangerous, and it causes

considerable damage to the generator. For the protection of stator winding of the generator, the differential

protection system is used for clearing the fault in the shortest possible time for minimizing the extent of a

damage.FLIGHT CONTROLS

Electrohydraulic servo valve (General Info)

An electrohydraulic servo valve (EHSV) is an electrically operated valve that controls how hydraulic fluid is

ported to an actuator. Servo valves and servo-proportional valves are operated by transforming a changing

analogue or digital input signal into a smooth set of movements in a hydraulic cylinder. Servo valves can

provide precise control of position, velocity, pressure and force with good post movement damping

characteristics. A low voltage is used to control the servo valve. The control voltage is passed into an amplifier

which provides the power to alter the valve's position. The valve will then deliver a measured amount of fluid

power to an actuator. The use of a feedback transducer on the actuator returns an electrical signal to the

amplifier to condition the strength of the voltage to the servo valve.NORMAL LAW

SPIRAL INSTABILITY: A condition that exists when the static directional stability of the airplane is very strong

as compared to the effect of its dihedral in maintaining lateral equilibrium. In a banked attitude sideslip forces

will try to roll the wings level but stable directional forces will try to yaw the aircraft to line it up with the new

relative airflow. The yaw will produce a rolling moment opposing the sideslip-induced roll. If the aircraft bank

steadily increases, leading to a spiral dive, it is spirally unstable. If the aircraft bank stays there then its

neutrally stable, and if it rolls out then its positively stable from a spiral. Simply pulling the nose up may not

reduce the speed when beyond a certain bank angle, so a "level the wings" command is made when high speed protection is operative.SLATS FLAPS

HYDRAULIC SYSTEM

INDICATING / RECORDING SYSTEMS

In general terms, a data concentrator is a software and hardware solution that connects a number of data

channels with one destination. Data Concentrator Unit collects and converts analog flight data into

informative digital readouts for aircraft pilots.Energy Circle: It is the distance required to go down, slow down, configure the aircraft and land at destination.

In a straight line, not taking account of the F-PLAN route. To use it, imagine a straight line to the runway, and

a/c on the centerline, if the energy circle is beyond the runway, you have too much energy and will have to

take appropriate action. If the circle lies between you and the runway - no problem.No Computed Data (NCD) means that a source is valid but the data is not in the valid range. When data is

marked as NCD by its source, all symbology dependent on that data will be removed from the display. No

failure flags will be displayed for NCD data. In NCD Airspeed - The precision tape digits and bugs will be

removed. The tape shading and scale marks remain.LANDING GEAR

BRAKE AND ANTISKID

AUTOBRAKE

For all old and new MSN types:

PNEUMATIC SYSTEM

ENGINES

AXIAL FLOW COMPRESSOR:

Aerofoil section blades or "rotors" mounted on a rotating rotor disc accelerate the air towards a set of

stationary "stator" blades. Stator blades are arranged to form a series of divergent ducts which convert kinetic

energy to pressure energy. Each set of rotors and stators is called a "stage". Across rotors; velocity, pressure

and temperature increase. Across stators; velocity reduces increasing pressure and temperature. Across

multiple stages; steady increase in pressure and temperature while velocity remains approximately constant.

Second function of the stator is to correct the air deflection from rotors ensuring that it is presented at the

correct angle to the next stage of rotors. Pressure rise across a single stage is small (10-20%) because of low

rate of diffusion and the angle of deflection to avoid blade stall or drag. Thus axial flow compressor requires

many stages. To keep the flow moving against the steady rise in pressure, the entire compressor assembly is

located in a convergent duct (air annulus). That is why rotors and stators at the high-pressure end of the

compressor are shorter than those at the inlet. Compression ratio of an axial compressor is generally 35:1

COMPRESSOR:

COMPRESSOR STALL:

ANATOMY OF A COMPRESSOR STALL:

VARIABLE INLET GUIDE VANES AND VARIABLE STATOR VANES:The rotor blades are fixed to give an optimum angle of attack at the design operating speed of the aircraft

and engine. At low axial speeds and high rotational speed the angle of attack will be high. During engine

start (no forward speed) the angle of attack on the first stage rotor blades could exceed their stalling angle.

To prevent this variable inlet guide vanes (VIGV) are fitted which adjust their angle to ensure that air is

directed onto the first stage at precisely the correct angle across all operating conditions. Same principle can

be applied to the stator vanes (Variable Stator Vanes) to ensure that the air leaving one compressor stage

arrives at the next at precisely the correct angle over the entire operating range of the engine.BLEED VALVES:

High Pressure Turbine Clearance Control: Case coverings are thin and closer to the fire and get hotquicker than thick turbine disks. Therefore, they expand quicker under the heat and open up blade tip

clearances which reduce engine efficiency. The idea is to slow down the heating rate of the cases until

the thick turbine rotor disks can catch up, so you meter some cooling air around the outside of the case

for a period of time to adjust the differences in thermal growth. Active Clearance Control: The invention relates to a control system which controls the diameter of a turbine shroud which surrounds a turbine in a gas turbine aircraft engine. The invention seeks to minimize the clearance between the turbine rotor and the shroud. Air is bled from the compressor inthe engine and ducted to the shroud in order to heat or cool the shroud in order to, respectively, either

expand or shrink the shroud to a proper diameter. The air temperature which is required is computed based on compressor speed and other engine parameters, but not upon directly measured rotortemperature, despite the fact that rotor temperature has a significant influence upon rotor diameter, and

thus upon shroud diameter needed. Air at two different temperatures is bled from two different

compressor stages in the engine and mixed together in a ratio which is determined according to flight

conditions, in order to provide air of the required temperature for the shroud, and then ducted to the

shroud in order to modify shroud size. Further, during accelerations and decelerations of the engine, a

different air temperature is provided, as compared with that provided during steady state operation. In

the event that the system just described should fail, back-up systems control shroud diameter. Thereexist two back-up systems, one for use during steady state, and the other for use during accelerations

and decelerations.IGNITION & STARTING

Thermal Bow:

In turbine engines, Rotor Bow, or thermal bowing, is normally due to asymmetrical cooling after shut-down

on the previous flight. Differences in temperature across the shaft section supporting the rotor lead to

different thermal deformation of the shaft material, causing the rotor axis to bend. This results in an offset

between the center of gravity of the bowed rotor and the bearing axis, causing a slight imbalance and

potentially reducing the tight clearance between the rotor blade tips and the compressor wall. Maintaining

this clearance as closely as possible is critical to engine efficiency. Slower starting allows more even heating,

eliminating differential thermal deformation. Operating an engine in the bowed-rotor condition causes

unnecessary wear-and-tear, reduces critical seal clearances, and may even be catastrophic due to high levels

of vibration. FUEL APUOXYGEN

CB PANELS

TRANSPONDER

PREDICTIVE WINDSHEAR

WX RADAR

GPWS TCAS 2000: The TCAS 2000 system provides pilots with the highest bearing determination accuracy andextended range surveillance. The TCAS 2000 delivers significantly improved reliability (as compared to the 1st

generation TCAS II systems) and provides substantial operating cost savings through its reduced weight and

power dissipation. See the link for more details:T2CAS: The T²CAS safety avionics system combines actual aircraft climb performance-based Terrain

Awareness Warning System (TAWS) capabilities into the TCAS 2000 line-replaceable unit (LRU). T²CAS is the

only TAWS to provide avoidance alerts based on actual aircraft performance data, virtually eliminating

nuisance warnings. Along with optional Windshear and GPS, the system provides a powerful combination of

functionality. See the link for more details:T3CAS: The T3CAS is a unique integrated surveillance equipment. This equipment features in one single unit

a Traffic Collision Avoidance System (TCAS), a Terrain Avoidance Warning System (TAWS) and a Mode Stransponder, saving the airline significant weight, space and power consumption, which in turn translates

into fuel savings. See the link for more details:T2CAS versus EGPWS: Difference between T2CAS and conventional TAWS systems is the use of actual aircraft

performance in T2CAS, as compared with the look-ahead parameters and fixed climb angle used in EGPWS.

Where T2CAS can change its look-ahead constraints based on real-world conditions and depending on aircraft

model, EGPWS uses a more or less static protection envelope. The benefit of the former is that additional

safety margins are built in depending on real-world factors. When everything is going wrongʹsay, the loss of

an engine at night in poor weatherʹ EGPWS may not always provide adequate protection to clear terrain

by the engine failure. T2CAS, on the other hand, considers an array of factors and adjusts its protection

envelope to ensure that the aircraft can climb above terrainʹor turn away from the hill or mountainʹwith

time to spare.rather than the more common pull-up command. It is easy to glance at the terrain display to determine what

type of action is required to avoid the portion of the screen where black Xs on red terrain warns that a climb

is not advisable. The system is designed so that a standard-rate turn away from the red portion of the display

is sufficient to avoid the terrain. Same message appears in some models where instead of position any required predictive function is missing or considered invalid TCASAP/FD TCAS mode is a vertical guidance mode built into the Auto Flight computer. It controls the vertical speed (V/S)

of the aircraft on a vertical speed target adapted to each RA, which is acquired from TCAS. With the Auto Pilot engaged,

it allows the pilot to fly the TCAS RA maneuvre automatically. With the Auto Pilot disengaged, the pilot can fly the TCAS

RA maneuvre manually, by following the TCAS Flight Director pitch bar guidance. It has to be considered as an add-on

to the existing TCAS features (traffic on Navigation Display, aural alerts, vertical speed green / red zones materializing

the RA on the Vertical Speed Indicator).NAVIGATION

GPS ISIS RMP FIREEngine Fire Test

APU Fire Test

Was this document helpful? Click here to Answer!

Disclaimer: "A320 Technical Notes" are personal notes of the undersigned for training only. These notes do not sanction any

pilot to violate his/her Company's Standard Operating Procedures, Aircraft Manuals or Manufacturer's Recommendations.

quotesdbs_dbs14.pdfusesText_20[PDF] airbus a321

[PDF] airbus a321neo price

[PDF] airbus a330 200

[PDF] airbus a330 300 seat plan

[PDF] airbus a330 300 seating

[PDF] airbus a330 300 seating plan

[PDF] airbus a330 price

[PDF] airbus a330 seating

[PDF] airbus a350

[PDF] airbus a350 1000

[PDF] airbus a350 manual pdf

[PDF] airbus a350 price

[PDF] airbus a350 price in indian rupees

[PDF] airbus a380 800 air france