CCF Bulletin Template

CCF Bulletin Template

18.11.2016 COCA-COLA NORTH AMERICA EQUIPMENT BULLETIN. SERVICE. DATE: November 18 ... SUBJECT: Replacing Elstat EMS-55 w/ Electronic Control on True Coolers.

Work Aid

Work Aid

If display shows PF1 change the ems controller. cooler lights do not switch on Set to 0 (display the word USE). set by. Coca-Cola set by OEM set by division.

EMS-55-(R) Instruction Manual

EMS-55-(R) Instruction Manual

The EMS has a second temperature sensor for the discharge line which is used to avoid the refrigeration system overheating. The compressor manufacturer will

Elstat-Training-Booklet.pdf

Elstat-Training-Booklet.pdf

GDM SERIES COOLER EQUIPPED WITH EMS (ELSTAT) CONTROL. ELSTAT COMPONENTS. Probe. Transformer. Controller. 1 2. 3. 4. 5 6. 7. 8. 9. Probe Location 2. Evaporator

CCF Bulletin Template

CCF Bulletin Template

COCA-COLA REFRESHMENTS EQUIPMENT BULLETIN. GENERAL. DATE: January 7 2014. NUMBER: GEN-125. SUBJECT: Elstat EMS-55. SUMMARY. Effective June 1

BTR 072D-11-09 Controlador EMS-55 Advanced

BTR 072D-11-09 Controlador EMS-55 Advanced

19.10.2012 Encaminhar o caso para a equipe técnica. Coca-Cola... Um alarme de falha do sensor indica que o controlador ...

green the capitol with energy-efficient vending machines: a field study

green the capitol with energy-efficient vending machines: a field study

1211) and two Coca-Cola machines (Watts Up 1219 For example if a vending machine goes unused on a weekend

GDM-43 COKE 115V

GDM-43 COKE 115V

927425 CONTROL TEMPERATURE

Service manual

Service manual

'Small'Cassette with EMS-55 Advanced electronic controller. Unit model ELSTAT EMS. Controller. BN. BU. BN. BN. S2-2 P2-2. T1-4. BN. T1-3. BN. S6-3. S7-4 P7-4.

Untitled

Untitled

Manual de Instrucciones EMS-55-(R). DESCRIPCIÓN GENERAL. El EMS ahorra energía permitiendo que la temperatura de la vitrina aumente durante períodos en los.

BTR 072D-11-09 Controlador EMS-55 Advanced

BTR 072D-11-09 Controlador EMS-55 Advanced

19 oct 2012 Encaminhar o caso para a equipe técnica. Coca-Cola... Um alarme de falha do sensor indica que o controlador ...

CCF Bulletin Template

CCF Bulletin Template

COCA-COLA NORTH AMERICA EQUIPMENT BULLETIN. SERVICE. DATE: November 18 2016 SUBJECT: Replacing Elstat EMS-55 w/ Electronic Control on True Coolers.

Service manual

Service manual

Programming the EMS Controller . 'Small'Cassette with EMS-55 Advanced electronic controller ... summarised in ELSTAT firmware release notes. IMPORTANT.

CCF Bulletin Template

CCF Bulletin Template

COCA-COLA REFRESHMENTS EQUIPMENT BULLETIN SUBJECT: Elstat EMS-55 ... installation of the EMS 55 (Energy Management System) in newly manufactured coolers ...

Elstat-Training-Booklet.pdf

Elstat-Training-Booklet.pdf

GDM-45 to GDM-72. Probe is in the discharge air stream. Off of the Evaporator Coil. GDM SERIES COOLER EQUIPPED WITH EMS (ELSTAT) CONTROL. ELSTAT COMPONENTS.

Work Aid

Work Aid

EMS55A-WORKAID-PARAMETERS-Iss3 ems55advanced work aid connected to the ems controller. ... Parts are available for purchase from Coca-Cola Parts.

Service manual

Service manual

EMS-55 Advanced with motion detector summarised in ELSTAT firmware release notes. IMPORTANT. The EMS Advanced controller must only be adjusted by an.

GDM-43 COKE 115V

GDM-43 COKE 115V

927425 CONTROL TEMPERATURE

EMS55 Controller for SRMCD620DAUWE_im.pdf

EMS55 Controller for SRMCD620DAUWE_im.pdf

EMS-55 CONTROLLER. -WIRING DETAILS. 1. BUTTON COMANDS. HT ALARM INDICATOR LIGHT. FAN ON INDICATOR LIGHT. COMPRESSOR ON INDICATOR LIGHT. Elstat.

6

6 Specifications

Service ManualSKOPE B600-2/B600G-2

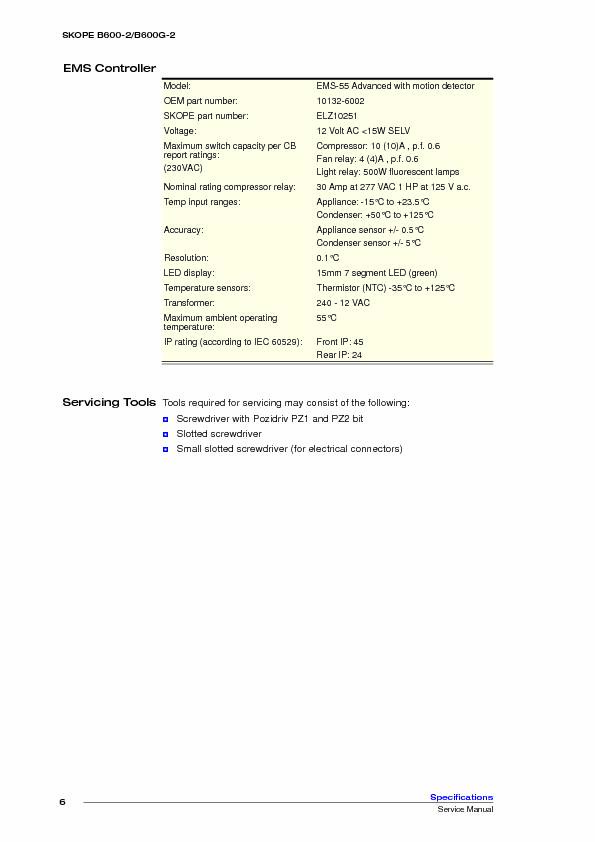

EMS Controller

Servicing ToolsTools required for servicing may consist of the following:Screwdriver with Pozidriv PZ1 and PZ2 bit

Slotted screwdriver

Small slotted screwdriver (for electrical connectors)Model:EMS-55 Advanced with motion detector

OEM part number:10132-6002

SKOPE part number:ELZ10251

Voltage:12 Volt AC <15W SELV

Maximum switch capacity per CB report ratings:

(230VAC)Compressor: 10 (10)A , p.f. 0.6Fan relay: 4 (4)A , p.f. 0.6Light relay: 500W fluorescent lamps

Nominal rating compressor relay:30 Amp at 277 VAC 1 HP at 125 V a.c. Temp input ranges:Appliance: -15°C to +23.5°CCondenser: +50°C to +125°C

Accuracy:Appliance sensor +/- 0.5°C

Condenser sensor +/- 5°C

Resolution:0.1°C

LED display:15mm 7 segment LED (green)

Temperature sensors:Thermistor (NTC) -35°C to +125°CTransformer:240 - 12 VAC

Maximum ambient operating temperature:55°C

IP rating (according to IEC 60529):Front IP: 45

Rear IP: 24

7SKOPE B600-2/B600G-2

EMS Controller

Service Manual

2 EMS Controller

EMS Controller Operations

IntroductionThe Energy Management System (EMS) Advanced controller is visible on the front panel and is mounted within the cassette electrics box on the front of the refrigeration cassette. The EMS Advanced controller detects variable business hours and switches the chiller to active mode approximately three hours prior to opening, and then changes to stand-by mode approximately half an hour after close of business. While in the economical stand-by mode the cabinet lights turn off, the fans cycle on and off and the chiller operates at a higher internal temperature.FirmwareThe firmware version is displayed on the digital display when the EMS Advanced controller is powered up. See the table below for current firmware versions:

Some differences exist between the two firmware versions. These differences are noted throughout this chapter where applicable and are summarised in ELSTAT firmware release notes.IMPORTANT

The EMS Advanced controller must only be adjusted by an authorised service agent.Figure 1: EMS

Advanced controller

Date rangeFirmware version

Pre Sept 2012U01-r02

From Sept 2012U01-n01

8EMS Controller

Service ManualSKOPE B600-2/B600G-2

FaceplateBecause the controller plays such an important role, it's helpful to know the parts of the faceplate you will use.No. ItemDescription

1 Defrost button. Manually activates an additional defrost cycle, and used to program the controller. The first automatic defrost occurs six hours after the first off-cycle. 2 Set button. Used to program the controller. 3 Infrared motion sensor. It detects activity within five metres around the front of the chiller, and feeds the data to the EMS advanced controller.4LED for the compressor light - green when compressor on.

5LED for the evaporator fan - green when evaporator fan on.

6LED indicating perishable mode - red when on.

Normal condition should be lit because the chiller is factory set for perishable product, which are high risk foods likely to support the growth of harmful bacteria. Perishable mode requires more energy. When chilling non-perishable product, perishable mode can turned off to save energy. 7 LED linked to the motion sensor and flashes red when there is activity around the chiller, but otherwise off. 8 Up button. Used to program the controller and cancel rSF and Ht alarms. 9Down button. Used to program the controller.

10 Digital display of cabinet temperature or messages (see next page for details). The temperature is what the sensor inside the chiller detects, and not necessarily the product temperature. However, they may be very close depending on how the controller is set to sense temperature.quotesdbs_dbs2.pdfusesText_2[PDF] email english pdf

[PDF] email professionnel en anglais exemple

[PDF] email without knowing the name

[PDF] embarazo definicion medica

[PDF] embarcadère de royan royan

[PDF] embarque hacia un nuevo mundo

[PDF] embranchement biologie

[PDF] embranchement des animaux

[PDF] embranchement des spermaphytes et cycles de developpement

[PDF] embranchement des vertébrés

[PDF] emc 3ème 2017

[PDF] emc biologie ethique et environnement

[PDF] emc discrimination 5ème

[PDF] emc discrimination cycle 3