Learning Applications about Standard Service Operational

Learning Applications about Standard Service Operational

One of the SOPs that the waiter must understand in serving food and beverage services is the Table Set-Up. * Corresponding author: arief.sukmandhani@binus

OCAD University

OCAD University

All unused food and beverages must be removed immediately following an event. • A SOP application must be obtained from Campus Services & Security or ...

TR Food and Beverage Services NC II

TR Food and Beverage Services NC II

TESDA-SOP-QSO-01-F08. TR – Food and Beverage Services NC II (Amended). Promulgated December 2013. 24. UNIT OF COMPETENCY : PERFORM WORKPLACE AND SAFETY

Food & Beverage Service

Food & Beverage Service

Use hot water and soap. Page 16. 16. Food & Beverage Service. Student's Manual. Introduction to Food Service Industry. Learning Objective: Student will able to

Level 2 Diploma in Food and Beverage Service (8064-03) - City

Level 2 Diploma in Food and Beverage Service (8064-03) - City

• Use standard operating procedures for telephone communication document free of charge and/or include a PDF version of it on centre intranets on the ...

Operating Procedures for the Army Food Program

Operating Procedures for the Army Food Program

17 Jul 2019 service SOP

[PDF] Food and Beverage Services - Tutorials Point

[PDF] Food and Beverage Services - Tutorials Point

The F&B Services providing businesses deliver food and beverages to their customers at a particular location (on-premise) such as hotel restaurant

STATE OF ALASKA STANDARD OPERATING PROCEDURE

STATE OF ALASKA STANDARD OPERATING PROCEDURE

22 Jun 2016 Division of General Services. S.O.P.#. Page 1 of 1. SUBJECT: Food & Beverage. Control. EFFECTIVE DATE: 08/01/2006. WRITTEN BY: Tanci Mintz.

S.EP 13 2011

S.EP 13 2011

5 Apr 2011 Corps Food Service SOP and in ref (b) The Marine Corps Field ... Food and Beverage Containers. This equipment will support expeditionary feeding ...

Food and Beverage Services - Tutorials Point

Food and Beverage Services - Tutorials Point

food garnishes and accompaniments and various standard operating procedures followed by food and beverage service business. This tutorial teaches basic

Sanitation & Food Safety Standard Operating Procedure Manual

Sanitation & Food Safety Standard Operating Procedure Manual

03-Jul-2018 UND attire in the food preparation and service area. ... Food and beverage cannot be stored or eaten in employee dressing rooms.

Hospital Catering Policy Provision of Food to Patients Staff and

Hospital Catering Policy Provision of Food to Patients Staff and

08-Mar-2022 Inserted Patient Meal Service Standard ... Equipment Standard Operating Procedure ... APPENDIX 2 – PATIENT FOOD AND BEVERAGE SERVICE .

STANDARD OPERATING PROCEDURE (SOPs)

STANDARD OPERATING PROCEDURE (SOPs)

Course Name: Food and Beverage Service Management. STANDARD OPERATING PROCEDURE. (SOP's). Objectives :- 1. To understand the meaning and definition of bar

QP-Food & Beverage Service -Steward.pdf

QP-Food & Beverage Service -Steward.pdf

04-Jul-2014 standard operating procedures. PC21. check service ware for chips marks

JOB DESCRIPTION FOR: Food & Beverage Manager

JOB DESCRIPTION FOR: Food & Beverage Manager

Job Summary: The Food & Beverage Manager is responsible for leading the food and beverage service staff in facilities to include the Club Room Grill Room

Food and Beverage Service - Model Curriculum

Food and Beverage Service - Model Curriculum

25-Mar-2016 Food & Beverage Service - Steward THC/Q0301 Version. 1.0 ... Plan for serving food and beverages: ... customers according to SOP and provide.

KRA 1: Food and Beverage service Responsibilities KPIs

KRA 1: Food and Beverage service Responsibilities KPIs

In line with SOP's sound working knowledge of product services and implemented changes with food and beverage menu's. Addressing in a professional

Sequence-of-Service-SOP.pdf

Sequence-of-Service-SOP.pdf

Remove menus to side station (both Beverage and Food). 7. Check all guests have the correct cutlery for their meal and change where necessary. 8. Call Starters

HACCP-Based Standard Operating Procedures (SOPs)

HACCP-Based Standard Operating Procedures (SOPs)

U.S. Department of Agriculture Food and Nutrition Service

STANDARD OPERATION PROCEDURES FOOD & BEVERAGE

STANDARD OPERATION PROCEDURES FOOD & BEVERAGE

STANDARD OPERATION PROCEDURES FOOD BEVERAGE KITCHEN Agenda 1 Kitchen Basics 1 01 Company Introduction Mission Statement 1 02 Benefits Of Training 1

SOP - Food and Beverage Trainer

SOP - Food and Beverage Trainer

1000 $US

[PDF] sop manual food & beverage department

[PDF] sop manual food & beverage department

CONSISTENCY – Everything from our tables table settings the way food is prepared and presented should be done in one set manner

Food And Beverage Service SOP - Setupmyhotelcom

Food And Beverage Service SOP - Setupmyhotelcom

Sample Standard Operating Procedure or SOP's for Hotel Food and Beverage / F&B Service Department Banquet SOP IRD SOP In Room Dining SOP BAR SOP

[PDF] Standard Operating Procedures Food & Beverage - Bar - PDF4PRO

[PDF] Standard Operating Procedures Food & Beverage - Bar - PDF4PRO

Standard Operating Procedures Food Beverage - Bar 1 Service Experience 1 01 Company Introduction Mission Statement 1 02 Benefits Of Training 1

Food and Beverage Service Sop PDF Tableware - Scribd

Food and Beverage Service Sop PDF Tableware - Scribd

FOOD AND BEVERAGE SERVICE SOP docx - Free download as Word Doc ( doc / docx) PDF File ( pdf ) Text File ( txt) or read online for free

SOP Standard Operating Procedures F&B Service (Room - Scribd

SOP Standard Operating Procedures F&B Service (Room - Scribd

Check order against KOT Check for correct crockery cutlery and glassware are in place Place hot food in warmer where ever appropriate Cover all open food

[PDF] Sanitation & Food Safety Standard Operating Procedure Manual

[PDF] Sanitation & Food Safety Standard Operating Procedure Manual

3 juil 2018 · UND attire in the food preparation and service area Food and beverage cannot be stored or eaten in employee dressing rooms

[PDF] Sequence-of-Service-SOPpdf

[PDF] Sequence-of-Service-SOPpdf

Remove menus to side station (both Beverage and Food) 7 Check all guests have the correct cutlery for their meal and change where necessary 8 Call Starters

What are the SOPs of food and beverage?

Foodservice industry standard operating procedures (SOPs) are written practices and procedures of how your establishment will produce safe food. SOPs are a key component of your overall food safety program. SOPs include specific details of how a policy will be implemented including: Who will perform the task.What does SOP mean food service?

Standard Operating Procedures (SOPs) are an important component of your food safety system because they ensure consistency in daily operations.What is an example of SOP in food industry?

Procedures: All food-processing employees should wash their hands before and after handling food products using the following methods: Scrub hands and forearms with hot, soapy water for at least 20 seconds. Rub hands together. Scrub forearms.- Definition of SOP ? An SOP is a set of written instructions that document a routine or repetitive activity. It is a set of detailed written instructions to achieve uniformity of the performance of a specific function.

Sanitation & Food Safety

Standard Operating

Procedure Manual

HACCP- Based Standard Operating Procedures

Revised

July 3rd, 2018

HACCP-Based Standard Operating Procedures

(Return to Table of Contents) iiTable of Contents

1. Employee Sanitation Standards

A. Personal Hygiene4

B. Hands Washing & Hand Washing Sink........6

C. Glove & Utensil Use When Handling Ready-to-Eat Foods..8D. Employee Uniforms0

E. Eating, Drinking, Taste Testing, & Breaks/Meals.13F. Employee Smoking/Tobacco Use.15

G. Employee Dressing Rooms17

H. Cuts, Burns or Lesions on Lower Arms or Hands19I. Contact with Blood & Bodily Fluids

J. Employee Illness.23

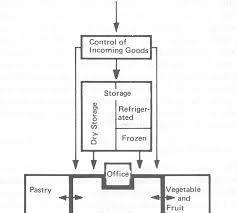

2. Storage & Receiving

A. Standards for Receiving Food Central Foods Warehouse26 B. Standards for Receiving Food All other Dining VenuesC. Handling Rejected Food33

D. Measuring Temperatures of Food Upon Receipt.36

E. Proper Training for Employees Who Store Food..38F. FIFO (First In, First Out) Stock Rotation40

G. Standards for Dry Storage.42

H. Standards for Cooler Storage44

I. Standards for Freezer Storage46

J. Standards for Bread Storage48

K. Corrective Action for Cooler & Freezer Temperatures503. Food Production

A. Controlling Time & Temperature During ProductionB. Acceptable Thawing Procedures....54

C. Using & Calibrating Thermometers

D. Date Marking & Ready to Eat (TCS) Food

E. Washing Fruits & Vegetables60

F. Cooking (TCS) Foods..62

G. Cooling (TCS) Foods...........................................65H. Holding Hot and Cold (TCS) Foods......................................................................68

I. Reheating (TCS) Foods70

J. Standards for Deli Foods & Salad Bars

JA. Deli Meats & Cheeses

K. Food Production Sinks78

HACCP-Based Standard Operating Procedures

(Return to Table of Contents) iii4. Food Safety

A. Preventing Cross Contamination During Storage & PreparationB. Removing Food from the Cooler

C. Transporting Food to Remote Sites (Satellite Kitchens)D. Unattended Food87

E. Serving Food

F. Temperature Logs for the Serving Areas

G. Acceptable Use of Leftovers93

H. Handling a Food Recall95

5. Cleaning & Sanitation

A. Employee Training on Sanitation

B. Storing & Using Poisonous or 99

C. Cleaning & Sanitizing Food Contact Surfaces

D. Dish Room Standard Operating Procedures105

E. Floor Maintenance110

F. Proper Storing of Equipment & Utensils

G. Emptying of Garbage Receptacles.116

H. Prevention of Vermin or Insect Infestation.118

I. Sanitation Inspections20

6. Incident Reports

A. Incident Rep122

7. Employee Alcohol & Drug Policy

A. Alcohol & Drug 124

8. Sanitation & Food Safety

Standard Operating Procedure Annual Training

A. Sanitation & Food Safety

B. Standard Operating Procedure Annual Training

HACCP-Based Standard Operating Procedures

(Return to Table of Contents) 41A: Personal Hygiene

PURPOSE: To prevent contamination of food by foodservice employees. SCOPE: This procedure applies to foodservice employees who handle, prepare, or serve food. KEY WORDS: Personal Hygiene, Cross-Contamination, ContaminationINSTRUCTIONS:

1. Train foodservice employees on using the procedures in this SOP.

2. Follow 2013 Grand Forks County Food Code Section General Personal Cleanliness 33-33-

04-293. Follow the Employee Illness SOP.

4. Report to work in good health, clean, and dressed in clean attire.

5. Change apron when it becomes soiled.

6. Wash hands properly, frequently, and at the appropriate times.

7. Fingernails are to be kept short and clean. No nail polish is allowed.

No artificial nails are permitted in the food production area.8. Keep hair clean and wear approved hair/beard restraints (i.e. hairnets, or a UND issued hat),

while working in the food preparation or serving areas.9. Bathe daily and wear acceptable amount of fragrance.

10. The only jewelry that may be worn while working in the food preparation or service areas is

wedding bands. No dangling jewelry or watches are allowed.11. No jewelry from visible piercings such as ears, lip, nose, eyebrow, tongue, etc. is to be worn

during shift.12. Report any illness to the manager on duty.

HACCP-Based Standard Operating Procedures

(Return to Table of Contents) 51A: Personal Hygiene, continued

MONITORING:

1. A direct supervisor will inspect employees when they report to work to be sure that each

employee is following this SOP.2. The direct supervisor will monitor that all foodservice employees are adhering to the above

stated employee policy during all hours of operation.CORRECTIVE ACTION:

1. Retrain any foodservice employee found not following the procedures in this SOP.

2. Discard affected food.

VERIFICATION AND RECORD KEEPING:

The direct supervisor will verify that foodservice employees are following this SOP by visually observing the employees during all hours of operation. The direct supervisor will complete the Food Safety Checklist daily. The Food Safety Checklist is to be kept on file for a minimum of 6 months. DATE IMPLEMENTED: __________________ BY: _______________________ DATE REVIEWED: _____________________ BY: _______________________ DATE REVISED: _______________________ BY: _______________________HACCP-Based Standard Operating Procedures

(Return to Table of Contents) 61B: Hand Washing & Hand Washing Sinks

PURPOSE: To prevent foodborne illness by contaminated hands. SCOPE: This procedure applies to anyone who handles, prepare, and serve food.KEY WORDS: Hand washing, Cross-Contamination

INSTRUCTIONS:

1. Train foodservice employees on using the procedures in this SOP.

2. Follow 2013 Grand Forks County Food Code Section General Personal Cleanliness 33-33-

04-293. Post hand washing signs or posters in a language understood by all foodservice staff near all

hand washing sinks, in food preparation areas, and restrooms.4. Use designated hand washing sinks for hand washing only.

Do not use food preparation, utility, and dishwashing sinks for hand washing.5. Provide warm running water, soap, and a means to dry hands.

Provide a waste container at each hand washing sink or near the door in restrooms.6. Keep hands washing sinks accessible anytime employees are present.

7. Wash hands:

Before starting work

During food preparation

When moving from one food preparation area to anotherBefore putting on or changing gloves

After using the restroom

After sneezing, coughing, or using a handkerchief or tissueAfter touching hair, face, or body

After touching clothing, shoes, or aprons.

After smoking, eating, drinking, or chewing gum or tobaccoAfter handling raw meats, poultry, or fish

After any clean up activity such as sweeping, mopping, or wiping counters After handling chemicals which could affect food safety. After touching dirty dishes, equipment, or utensilsAfter handling trash

After handling money

After any time the hands may become contaminated

HACCP-Based Standard Operating Procedures

(Return to Table of Contents) 71B: Hand Washing & Hand Washing Sinks, continued

8. Follow proper hand washing procedures as indicated below:

Wet hands and forearms with warm, running water at least 100 ºF and apply soap. Scrub lathered hands and forearms, under fingernails, and between fingers for at least 10-15 seconds. Rinse thoroughly under warm running water for 5-10 seconds.

Dry hands and forearms thoroughly with single-use paper towels.Turn off water using paper towels.

Use paper towel to open door when exiting the restroom.9. Follow FDA recommendations when using hand sanitizers.

These recommendations are as follows:

Use hand sanitizers only after hands have been properly washed and dried. Use only hand sanitizers that comply with the 2013 Grand Forks County Food Code. The hand sanitizers must be an alcohol-based hand sanitizer that contains at least 60% alcohol.MONITORING:

1. A direct supervisor will visually observe the hand washing practices of the foodservice staff

during all hours of operation.2. The direct supervisor will monitor that all foodservice employees are adhering to the above

stated employee policy during all hours of operation.CORRECTIVE ACTION:

1. Retrain any foodservice employee found not following the procedures in this SOP.

2. Ask employees that are observed not washing their hands at the appropriate times or using

the proper procedure to wash their hands immediately.VERIFICATION AND RECORD KEEPING:

The direct supervisor will complete the Food Safety Checklist daily to indicate that monitoring is being conducted as specified. The Food Safety Checklist is to be kept on file for a minimum of 6 months. DATE IMPLEMENTED: __________________ BY: _______________________ DATE REVIEWED: _____________________ BY: _______________________ DATE REVISED: _______________________ BY: _______________________HACCP-Based Standard Operating Procedures

(Return to Table of Contents) 81C: Glove & Utensils Use When Handling Ready-to-Eat Foods

PURPOSE: To prevent foodborne illness due to hand-to-food cross-contamination. All food will be served in a manner to ensure food safety SCOPE: This procedure applies to foodservice employees who prepare, handle, or serve food. KEY WORDS: Ready-to-Eat Food, Cross-ContaminationINSTRUCTIONS:

1. Train foodservice employees on using the procedures in this SOP.

2. Follow 2013 Grand Forks County Food Code Section General Equipment and Utensils

Materials and Use 33-33-04-32

3. Use proper hand washing procedures to wash hands and exposed arms prior to preparing or

handling food or at any time when the hands may have become contaminated.4. Do not use bare hands to handle ready-to-eat foods at any time unless washing fruits and

vegetables.5. Use suitable utensils when working with ready-to-eat food. Utensils should be cleaned and

sanitized at least once every two hours during continuous use.6. Suitable utensils may include:

Single-use gloves

Deli tissue

Foil wrap

Tongs, spoodles, spoons, and spatulas

7. Serving utensils can be stored in the food with the handle extended above the rim of the

container or placed on a clean, sanitized food-contact surface.8. Glassware and dishes should be held by handles or bottom of the dishes and not the food

contact areas. Flatware and utensils should be held at the handle.9. Glassware and dishes should not be stacked when serving.

Glasses should be carried on a rack or on a tray.

10. Wash hands and change gloves: Gloves must never be used in place of hand washing.

Before beginning food preparation

Before beginning a new task

At least every four hours during continual use, and more often when necessary. After touching equipment such as refrigerator doors or utensils that have not been cleaned and sanitized After finishing handling raw meat and before handling cooked or ready-to-eat foodsHACCP-Based Standard Operating Procedures

(Return to Table of Contents) 91C: Glove & Utensils Use When Handling Ready-to-Eat Foods,

continuedINSTRUCTIONS: continued

After contacting chemical

11. Cover cuts and sores on hands, including fingernails, with clean bandages. If hands are

bandaged, clean gloves or finger cots (blue protective coverings) should be worn at all times to protect the bandage and to prevent it from falling into food. Change gloves or finger cots as appropriate.MONITORING:

1. A direct supervisor will visually observe that gloves or suitable utensils are used and changed

at the appropriate times during all hours of operation.2. The direct supervisor will monitor that all foodservice employees are adhering to the above

stated employee policy during all hours of operation.CORRECTIVE ACTION:

1. Retrain any foodservice employee found not following the procedures in this SOP.

2. Discard ready-to-eat food touched with bare hands.

VERIFICATION AND RECORD KEEPING:

The direct supervisor will verify that foodservice workers are using suitable utensils by visually monitoring foodservice employees during all hours of operation. The direct supervisor will complete the Food Safety Checklist daily. The direct supervisor responsible for monitoring will record any discarded food on the Damaged and Discarded Product Log. The Food Safety Checklist and Damaged and Discarded Food Log are kept on file for a minimum of 6 months. DATE IMPLEMENTED: __________________ BY: _______________________ DATE REVIEWED: _____________________ BY: _______________________ DATE REVISED: _______________________ BY: _______________________HACCP-Based Standard Operating Procedures

(Return to Table of Contents) 101D: Employee Uniform Standards

PURPOSE: To prevent foodborne illness due to hand-to-food cross-contamination. SCOPE: This procedure applies to foodservice employees who prepare, handle, or serve food. KEY WORDS: Ready-to-Eat Food, Cross-ContaminationINSTRUCTIONS:

1. Train foodservice employees on using the procedures in this SOP.

2. Follow 2013 Grand Forks County Food Code Section General Personal Cleanliness 33-33-

04-293. Employees will change into the uniforms provided for them by UND after clocking in for

work.4. Employees must clock out at the end of their shift before changing out of their uniform.

5. Hair restraints such as hairnets, hair coverings (UND approved hats, skull caps, chef hats,

etc.) which covers 100% of hair, must be worn at all times when working in a food preparation or food serving area.6. Employees will change out of uniforms and into street clothes when leaving their dining

center for work purposes such as a meeting, working at different location, etc. They are to stay clocked in for this change of clothing.7. Employees leaving dining center for personal reasons, i.e. walking, appointment, etc., are to

change out of uniform after clocking out and change back into uniform before continuing shift (clocking back in).8. Employees going outside of dining center during a 15 minute break (such as going outside to

smoke or get fresh air) should remove lab coat, uniform jacket, smock, etc. before leaving.9. Employees will change their uniform/apron as necessary during the day (i.e. due to heavy

soil, etc.).10. Employees are to change their apron after working with raw meat or with any other

potentially hazardous food to prevent cross-contamination.11. Uniforms are not to be worn or taken home.

12. Employees are to wear closed toed, non-skid, closed heel shoes with leather/leather-like

uppers and nonabsorbent soles while working in the kitchen, dining room, or serving line.HACCP-Based Standard Operating Procedures

(Return to Table of Contents) 111D: Employee Uniform Standards continued

13. All management, guests, or employees with a shortage of uniforms must wear approved

UND attire in the food preparation and service area. See your supervisor if you have questions.14. Attire during shut down and cleaning must be approved by management staff. No shorts are

allowed. Uniforms are highly encouraged during cleaning to help prevent accidents. Dress Code: Casual Day - Spirit Day/Denim Day for Charity Policy: Only employees who are not involved in food production or serving of food will be allowed to participate in Casual Days - Spirit Day/Denim Day for Charity.Procedures:

1. Approved attire

a. Spirit Day: Pants: Casual no denim/chinos/khaki clean and neat without holesShirt/Top UND Related

UND Related Pin, hat, etc.

Footwear must be closed toe, closed heel shoes, non-skid b. Denim Day for Charity:Pants Denim clean and neat without holes,

Shirt/Top clean and neat, preferably UND-related, no shirts with profanity or obscenity Footwear must be closed toe, closed heel shoes, non-skid2. When participating in casual days employees must still adhere to sanitation standards

while in kitchen/serving areas by wearing hair restraints and lab jacket/apron, etc.HACCP-Based Standard Operating Procedures

(Return to Table of Contents) 121D: Employee Uniform Standards continued

MONITORING:

1. A direct supervisor will visually observe that proper uniforms are used and changed at the

appropriate times during all hours of operation.2. The direct supervisor will monitor that all foodservice employees are adhering to the above

stated employee policy during all hours of operation.CORRECTIVE ACTION:

1. Retrain any foodservice employee found not following the procedures in this SOP.

2. Discard affected food.

VERIFICATION AND RECORD KEEPING:

The direct supervisor will verify that foodservice workers are wearing suitable uniforms by visually monitoring foodservice employees during all hours of operation. The direct supervisor will complete the Food Safety Checklist daily. The direct supervisor responsible for monitoring will record on The Food Safety Checklist and keep on file for a minimum of 6 months. DATE IMPLEMENTED: __________________ BY: _______________________ DATE REVIEWED: _____________________ BY: _______________________ DATE REVISED: _______________________ BY: _______________________HACCP-Based Standard Operating Procedures

(Return to Table of Contents) 131E: Eating, Drinking, Taste Testing, & Breaks/Meals

PURPOSE: To prevent contamination of food by foodservice employees. Foodservice employees will eat and drink in designated areas outside of the kitchen. All foodservice employees will use the correct and sanitary tasting method to prevent contamination and ensure food safety. SCOPE: This procedure applies to foodservice employees who handle, prepare, or serve food. KEY WORDS: Personal Hygiene, Cross-Contamination, ContaminationINSTRUCTIONS:

1. Train foodservice employees on using the procedures in this SOP.

2. Follow 2013 Grand Forks County Food Code Section Preventing Contamination When

Tasting 33-33-04-09.1

3. All employees must:

a. Eat and drink in designated areas only, never in the work area. Eating (with the exception of cooks tasting foods to ensure quality) is NOT allowed in the production and service areas. b. Chew gum or eat candy only in areas designated for employees to eat.4. Taste testing is allowed in the kitchen using the Two Spoon Tasting Method:

a. Remove a sample of a product from the container with one spoon. b. Transfer the product sample onto a second spoon, away from the original food container or preparation area. c. Sample the product by tasting. d. Never re-use a used spoon. Note: Always use two spoons to ensure sanitary practices are being followed and the product is not contaminated. e. Any dishes or utensils used for tasting should be removed from the food preparation area for cleaning and sanitizing. f. Follow proper hand-washing procedures after testing.5. Breaks and meals must:

a. Be taken in a designated area away from production and service areas. b. Wash hands before returning to any foodservice area.HACCP-Based Standard Operating Procedures

(Return to Table of Contents) 141E: Eating, Drinking, Taste Testing, & Breaks/Meals, continued

MONITORING:

1. A direct supervisor will inspect employees when they report to work to be sure that each

employee is following this SOP.2. The direct supervisor will monitor that all foodservice employees are adhering to the above

stated employee policy during all hours of operation.CORRECTIVE ACTION:

1. Retrain any foodservice employee found not following the procedures in this SOP.

2. Discard affected food.

VERIFICATION AND RECORD KEEPING:

The direct supervisor will verify that foodservice employees are following this SOP by visually observing the employees during all hours of operation. The direct supervisor will complete the Food Safety Checklist daily. The Food Safety Checklist is to be kept on file for a minimum of 6 months. DATE IMPLEMENTED: __________________ BY: _______________________ DATE REVIEWED: _____________________ BY: _______________________ DATE REVISED: _______________________ BY: _______________________HACCP-Based Standard Operating Procedures

(Return to Table of Contents) 151F: Employee Smoking

PURPOSE: To prevent contamination of food by foodservice employees. Foodservice employees will smoke in designated areas outside of the kitchen. All foodservice employees will smoke in designated areas to prevent contamination and ensure food safety. SCOPE: This procedure applies to foodservice employees who handle, prepare, or serve food. KEY WORDS: Personal Hygiene, Cross-Contamination, ContaminationINSTRUCTIONS:

1. Train foodservice employees on using the procedures in this SOP.

2. Follow 2013 Grand Forks County Food Code Section General employee practices 33-33-04-

313. Refer to UND http://und.edu/health-wellness/healthy-und/tobacco-free-und/

4. Smoking is allowed outside in designated areas only.

They must be at least 20 feet from any door opening or venting into a building.5. Aprons, uniform tops and kitchen lab coats must be taken off and placed in the laundry

before going on a smoke break.6. Wash hands and put on a clean apron or lab coat upon returning from a smoke break, or any

type of break.MONITORING:

1. A direct supervisor will inspect employees when they report to work to be sure that each

employee is following this SOP.2. The direct supervisor will monitor that all foodservice employees are adhering to the above

quotesdbs_dbs14.pdfusesText_20[PDF] food delivery articles

[PDF] food delivery business plan sample pdf

[PDF] food delivery industry in malaysia pdf

[PDF] food delivery market in world

[PDF] food delivery market size global

[PDF] food delivery service business plan

[PDF] food delivery service marketing strategy

[PDF] food donation app project report

[PDF] food festival proposal pdf

[PDF] food for 1 year old

[PDF] food handler certification

[PDF] food home delivery business plan pdf

[PDF] food in hauts de france

[PDF] food industry report 2019