Powder metallurgy – basics & applications

Powder metallurgy – basics & applications

Steps in powder metallurgy: Powder production Compaction

Chapter 18: Powder Metallurgy

Chapter 18: Powder Metallurgy

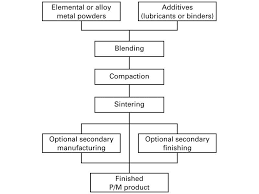

Figure 18-1 Simplified flow chart of the basic powder metallurgy process. Page 4. 18.3 Powder Manufacture. ▫ Properties of powder metallurgy products are

POWDER METALLURGY

POWDER METALLURGY

The powder metallurgy process consists of mixing elemental or alloy powder compacting the mixture in a die and then sintering or heating the resultant

POWDER METALLURGY

POWDER METALLURGY

Powder metallurgy process can be applied to not only metal materials but also ceramics and organic materials which both are employed as structural and

Unit 7 - week 6

Unit 7 - week 6

26-Jul-2020 The various processes carried out in powder metallurgy are as follows ... © 2014 NPTEL - Privacy & Terms - Honor Code - FAQs -.

Metal casting processes

Metal casting processes

Powder metallurgy & its applications (3 classes). Page 2. R.Ganesh Narayanan NPTEL course on Manufacturing processes – I Pradeep Kumar et al. J S Campbell ...

Unit 2 - Week 1

Unit 2 - Week 1

26-Jul-2020 As per our records you have not submitted this assignment. Powder metallurgy can be used for making simple two-dimensional parts but not those ...

POWDER METALLURGY

POWDER METALLURGY

COURSE OUTLINE : Powder Metallurgy is a very useful manufacturing process which is being practiced in variety of industries for decades. It is a versatile

POWDER METALLURGY

POWDER METALLURGY

Metal processing technology in which parts are produced from metallic powders. •In the usual PM production sequence the powders.

FUNDAMENTALS OF MATERIAL PROCESSING - I

FUNDAMENTALS OF MATERIAL PROCESSING - I

First part of the course deals with Solidification and Powder Metallurgy while the second part deals with Metal processing and. Thin film fabrication. ABOUT

Powder metallurgy – basics & applications

Powder metallurgy – basics & applications

Powder metallurgy – science of producing metal powders and making finished http://www.itponline.com/Presentations/ITA-2005.pdf ...

Chapter 18: Powder Metallurgy

Chapter 18: Powder Metallurgy

Figure 18-1 Simplified flow chart of the basic powder metallurgy process. Page 4. 18.3 Powder Manufacture. ? Properties of powder metallurgy products are

POWDER METALLURGY

POWDER METALLURGY

Powder Metallurgy (PM). Metal processing technology in which parts are produced from metallic powders. •In the usual PM production sequence the powders.

Unit 2 - Week 1

Unit 2 - Week 1

26-Jul-2020 https://onlinecourses-archive.nptel.ac.in/noc17_mm09/unit?unit= ... Powder metallurgy can be used for making simple two-dimensional parts ...

POWDER METALLURGY

POWDER METALLURGY

Powder metallurgy process can be applied to not only metal materials but also ceramics and organic materials which both are employed as structural and

POWDER METALLURGY

POWDER METALLURGY

POWDER METALLURGY. TYPE OF COURSE : Rerun

Theory and Practice of Non Destructive Testing

Theory and Practice of Non Destructive Testing

27-Mar-2022 ferrous and nonferrous metals powder metallurgy parts

Introduction to Interfacial Enginering

Introduction to Interfacial Enginering

NPTEL - Chemical Engineering - Interfacial Engineering Alloys cement

FUNDAMENTALS OF MATERIAL PROCESSING - I

FUNDAMENTALS OF MATERIAL PROCESSING - I

Materials Engineering Mechanical Engineering

Metal casting processes_1.pdf

Metal casting processes_1.pdf

(9 classes). Powder metallurgy & its applications (3 classes) NPTEL course on Manufacturing processes – I Pradeep Kumar et al.

DV03PUB20 - Powder Metallurgy Study Guide

DV03PUB20 - Powder Metallurgy Study Guide

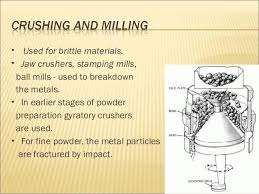

Powder Metallurgy Fundamental Manufacturing Processes Study Guide DV03PUB20 - 1 - Training Objective After watching the program and reviewing this printed material the viewer will gain a knowledge and understanding of the basics of powder metallurgy • Types of particles are explained • Mechanical pressing is detailed

Chapter 18: Powder Metallurgy

Chapter 18: Powder Metallurgy

Powder Metallurgy is a very useful manufacturing process which is being practiced in variety of industries for decades It is a versatile process that can produce a solid a component or a product in net shape or near net shape staring from a loose mass of powder

Advances in powder metallurgy : Properties processing and

Advances in powder metallurgy : Properties processing and

7 5 Powder injection moulded steel components 186 7 6 Powder metallurgy tool steels 190 7 7 Trends in ferrous powder metallurgy 195 7 8 Acknowledgements 196 7 9 Further reading 196 7 10 References 198 8 Powder metallurgy of titanium alloys 202 F h Fr o e S Consultant USA 8 1 Introduction 202 8 2 Powders 204

NPTEL Syllabus - Manufacturing Processes I

NPTEL Syllabus - Manufacturing Processes I

Powder Metallurgy Introduction Production of metal powders Compaction and sintering processes Secondary and finishing operations Economics advantages and applications of powder metallurgy Metal Casting Introduction: Brief History Advantages and Limitations Applications Patterns: Pattern materials allowances types of pattern color

Unit 7 - week 6 - NPTEL

Unit 7 - week 6 - NPTEL

The various processes carried out in powder metallurgy are as follows i preparation of powder ii Sintering iii Blending of powder iv Compacting of powder The correct sequence is i ii iii iv i iii iv ii ii i iii iv iii i ii iv No th e an sw er i s i n co rrect S co re: 0 Accep ted An sw ers: i iii iv ii

Searches related to powder metallurgy pdf nptel filetype:pdf

Searches related to powder metallurgy pdf nptel filetype:pdf

Figure 2 Factors determining the properties of powder metallurgy products Preparation of alloyed powders Alloy P/M steel parts can be made from mixtures of elemental powders from prealloyed powders or from hybrid processing involving alloy additions to prealloyed powders of lower alloy content Several references were found

What is powder metallurgy?

- ?Powder metallurgy is the name given to the process by which fine powdered materials are blended, pressed into a desired shape, and then heated to bond surfaces ?Typically used when large amounts of small, intricate parts with high precision are required

What are the disadvantages of powder metallurgy?

- ?Inferior strength properties ?High tooling costs ?High material cost ?Size and shape limitations ?Dimensional changes during sintering ?Density variations ?Health and safety hazards 18.17 Summary Powder metallurgy can produce products out of materials that are otherwise very difficult to manufacture

What is nickel- alloyed powder metal (p/m) steel?

- Nickel has found an important place as an alloying element in steels pro- duced from metal powders. The desire to attain consistent and improved mechanical properties in steel parts has led to increased use of nickel- alloyed powder metal (P/M) steel.

Who is the author of Chapter 18 of powder metallurgy?

- Chapter 18: Powder Metallurgy Author Darcy Wagner Created Date 7/25/2011 2:01:18 PM