Components of CNC

A computer numerical control (CNC) system consists of three basic components: CNC software that is a program of instructions, a machine control unit, and processing equipment, also called machine tool..

Components of CNC

CNC stands for Computerized Numerical Control.

It is a computerized manufacturing process in which pre-programmed software and code controls the movement of production equipment..

Components of CNC

Numerical Control (NC) refers to the method of controlling the manufacturing operation by means of directly inserted coded numerical instructions into the machine tool.

It is important to realize that NC is not a machining method; rather, it is a concept of machine control..

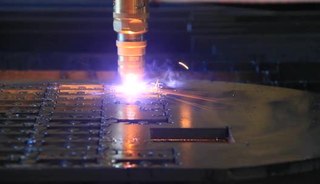

How accurate can a computer controlled cutting machine be?

In many cases, laser-cutting machines can consistently cut with an accuracy within the range of \xb10.05 to \xb10.2 mm (0.002 to 0.008 inches).

This level of accuracy is critical for applications requiring complex designs and tight tolerances..

How do you control a CNC machine?

A CNC system requires motor drives to control both the position and the velocity of machine axes.

Each axis must be driven separately, and must follow the command signal generated by the numerical control.

There are two ways to activate the servo drives; the open-loop system and the closed-loop system..

What is a CNC controller?

CNC controllers are computer numerically controlled (CNC) devices that control machines and processes.

They provide capabilities ranging from simple point-to-point linear control to highly complex algorithms with multiple axes of control.

CNC controllers are used to retrofit many types of machine shop equipment..

What is a numerically controlled machine called?

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer.

It is used to operate tools such as drills, lathes, mills, grinders, routers and .

- D printers

What is computer numerically controlled machine?

Computer numerical control (CNC) is a manufacturing method that automates the control, movement and precision of machine tools through the use of preprogrammed computer software, which is embedded inside the tools..

What is the advantage of numerical control machine?

They can run for 24 hours a day.

They can product jobs with higher accuracy and precision than other manual machines.

Operators can make changes easily, which reduces the delay time..

What is the CNC machine used for?

It is a computerized manufacturing process in which pre-programmed software and code controls the movement of production equipment.

CNC machining controls a range of complex machinery, such as grinders, lathes, and turning mills, all of which are used to cut, shape, and create different parts and prototypes..

What is the purpose of numerical control?

Computer numerical control (CNC) is a manufacturing method that automates the control, movement and precision of machine tools through the use of preprogrammed computer software, which is embedded inside the tools.

CNC is commonly used in manufacturing for machining metal and plastic parts..

What is the role of computer for CNC machine tool?

Computer plays a crucial role in controlling the operation of a Numerical Control (NC) machine.

The computer provides the necessary instructions to the NC machine, which then executes the operations as per the instructions received..

Who control the CNC machine?

Computer numerical control (CNC) is the control of machining tools through automation or computer programming.

A CNC machine follows coded instructions such as G-code and M-code.

These instructions are typically written by a person or by CAD/CAM software..

Why CNC is important in control system?

CNC helps to automate the fabrication process, thus improving repeatability and precision, reducing human error, and adding advanced capabilities (e.g., the direct conversion of CAD models to finished parts)..

- A CNC system requires motor drives to control both the position and the velocity of machine axes.

Each axis must be driven separately, and must follow the command signal generated by the numerical control.

There are two ways to activate the servo drives; the open-loop system and the closed-loop system.