inclusion métallurgie

|

Origine des inclusions dans les aciers peu alliés

La Revue de Métallurgie-GIT Avril 1995. Les inclusions non métalliques ( composés stables formés dans l'acier liquide avant la fin de sa solidification) |

|

Analyse d inclusions doxydes responsables de défauts de surface

1 ene 1984 inclusions a mechanism is proposed for the formation of internal defects in seamless tube. ... Revue métallurgie (1981) p.421-434. |

|

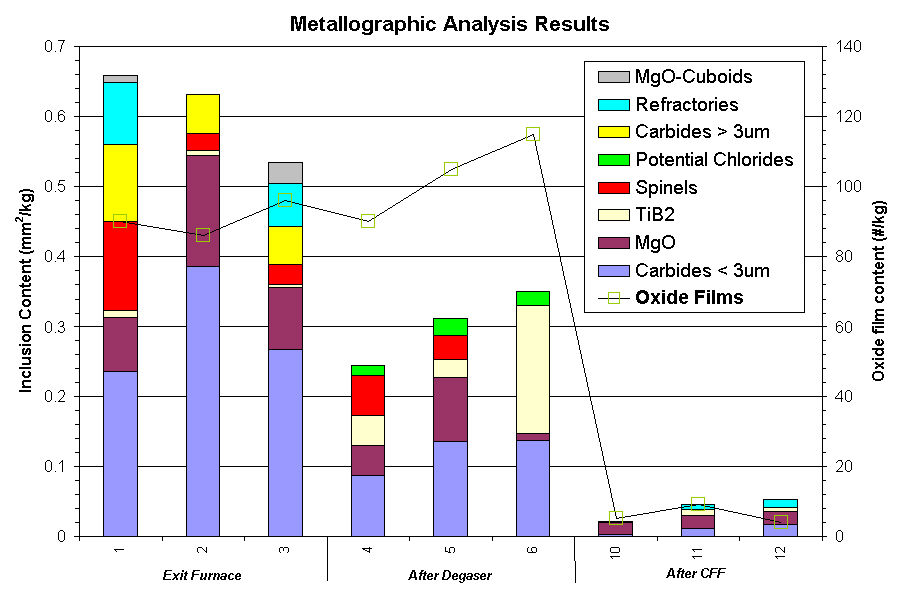

Caractérisation de la propreté inclusionnaire daciers de fonderie

17 abr 2020 La propreté inclusionnaire est un des enjeux de la métallurgie. ... Les principaux types d'inclusion détectés sont les oxydes petits |

|

Métallurgie physique

Rapport du Centre de Recherches Métallurgiques Liège Les inclusions sont très rares et les précipités à l'intérieur des grains ferri-. |

|

Le rapport de Jean-Marc Borello « Donnons-nous les moyens de l

L'inclusion économique et sociale est cependant un chantier plus vaste auquel tous les Union des industries et métiers de la métallurgie (UIMM). |

|

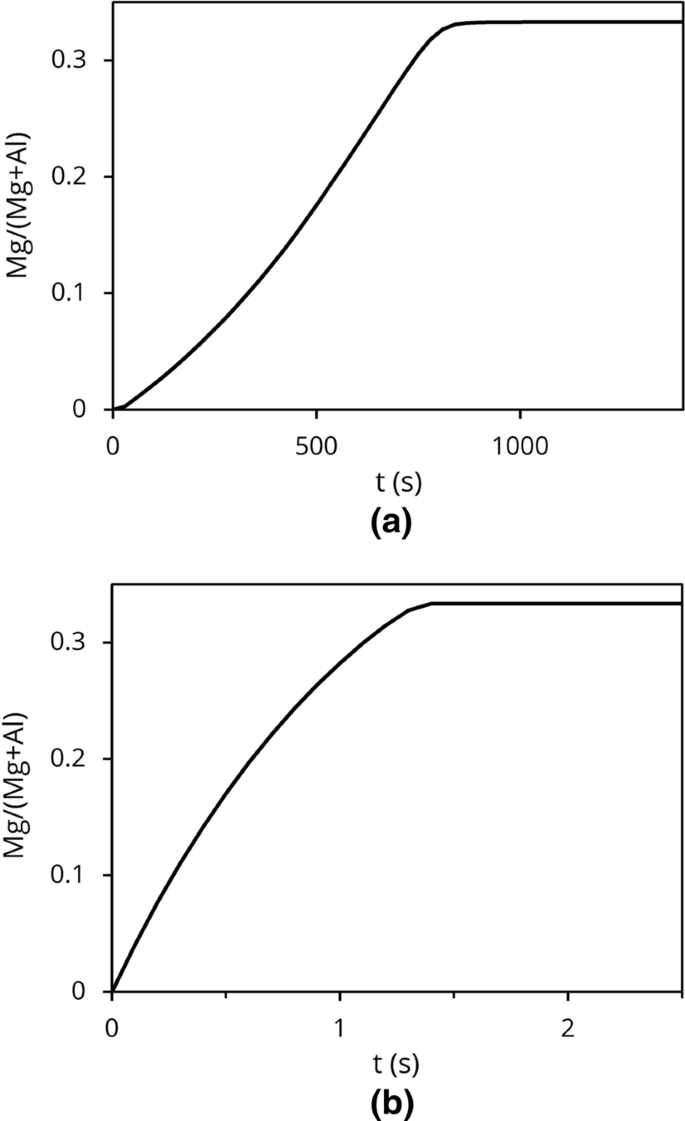

Inclusion behavior in an Aluminum bath stirred by induction

19 jul 2021 Pole M4 : matière matériaux |

|

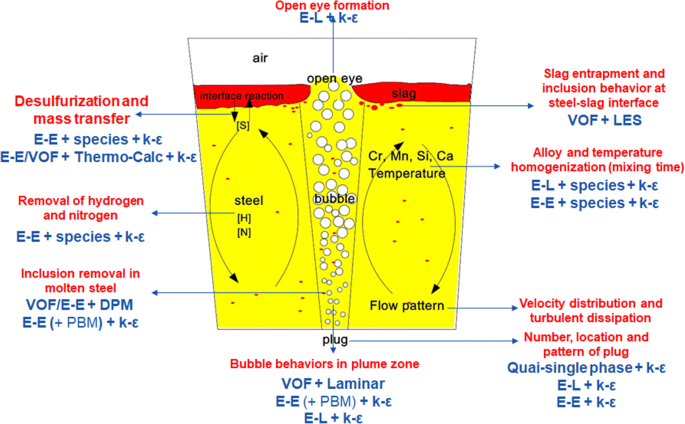

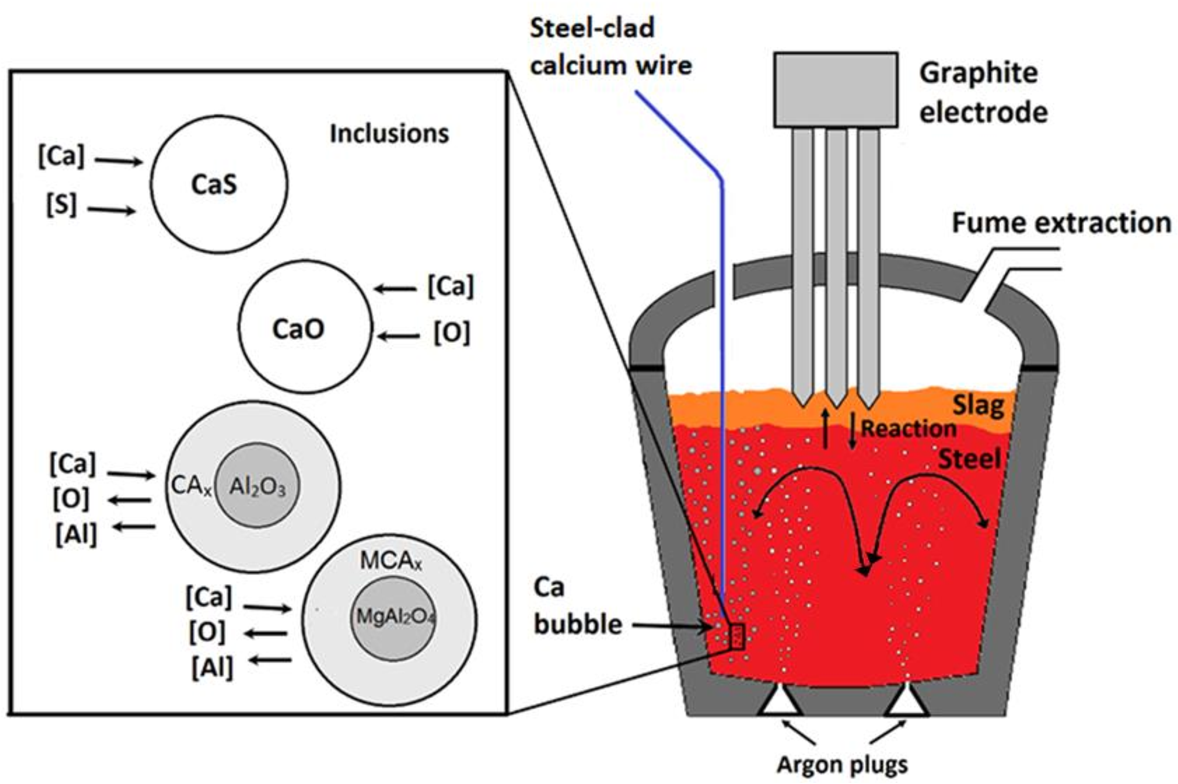

Réaction métal-laitier et contrôle de la composition des inclusions

et contrôle de la composition des inclusions résiduelles en métallurgie secondaire*. * Communication présentée au congrès « Clean Steel 3 » (Bala-. |

|

INDUSTRIELS ENGA GÉ S

inclusive l'UIMM La Fabrique de l'Avenir a signé une convention nationale avec l'Agefiph. Elle donne un nouvel élan à l'insertion professionnelle. |

|

INDUSTRIELS ENGA GÉ S

inclusive l'UIMM La Fabrique de l'Avenir a signé une convention nationale avec l'Agefiph. Elle donne un nouvel élan à l'insertion professionnelle. |

|

The Diversity Equity & Inclusion imperative in mining and metals

Inclusion refers to the practice of making all members of an organization feel welcome and giving them equal opportunity to connect belong grow and contribute to the organization while feeling comfortable and confident being their authentic selves It constitutes an environment where all individual di?erences are embraced5 |

|

Steel Cleanliness: Inclusions in Steel S

leaders to report a strong sense of inclusion Also the women who responded to our survey are less likely than the men to indicate that they feel a strong sense of inclusion While LGBTQ+ respondents’ degree of inclusion appears to be a bright spot this finding is likely influenced by that sample skewing toward more senior employees 9 |

|

MÉTALLURGIE - Dunod

Métallurgie sous tous ses aspects reste toujours au premier plan de l’actualité en Science des Matériaux Même l’importance considérable prise par les matériaux fonctionnels : céramiques semi-conducteurs ?lms minces matériaux nanostructurés n’occulte pas la place éminente de la métallurgie |

|

MIXITE ET EGALITE PROFESSIONNELLE DANS L’INDUSTRIE

dans la métallurgie) et stable depuis des décennies malgré les actions menées de longue date par les entreprises et leurs représentants Mais ce chiffre cache un constat sans doute plus préoccupant : les femmes occupent majoritairement des fonctions support et non au cœur de la conception et de la production : |

|

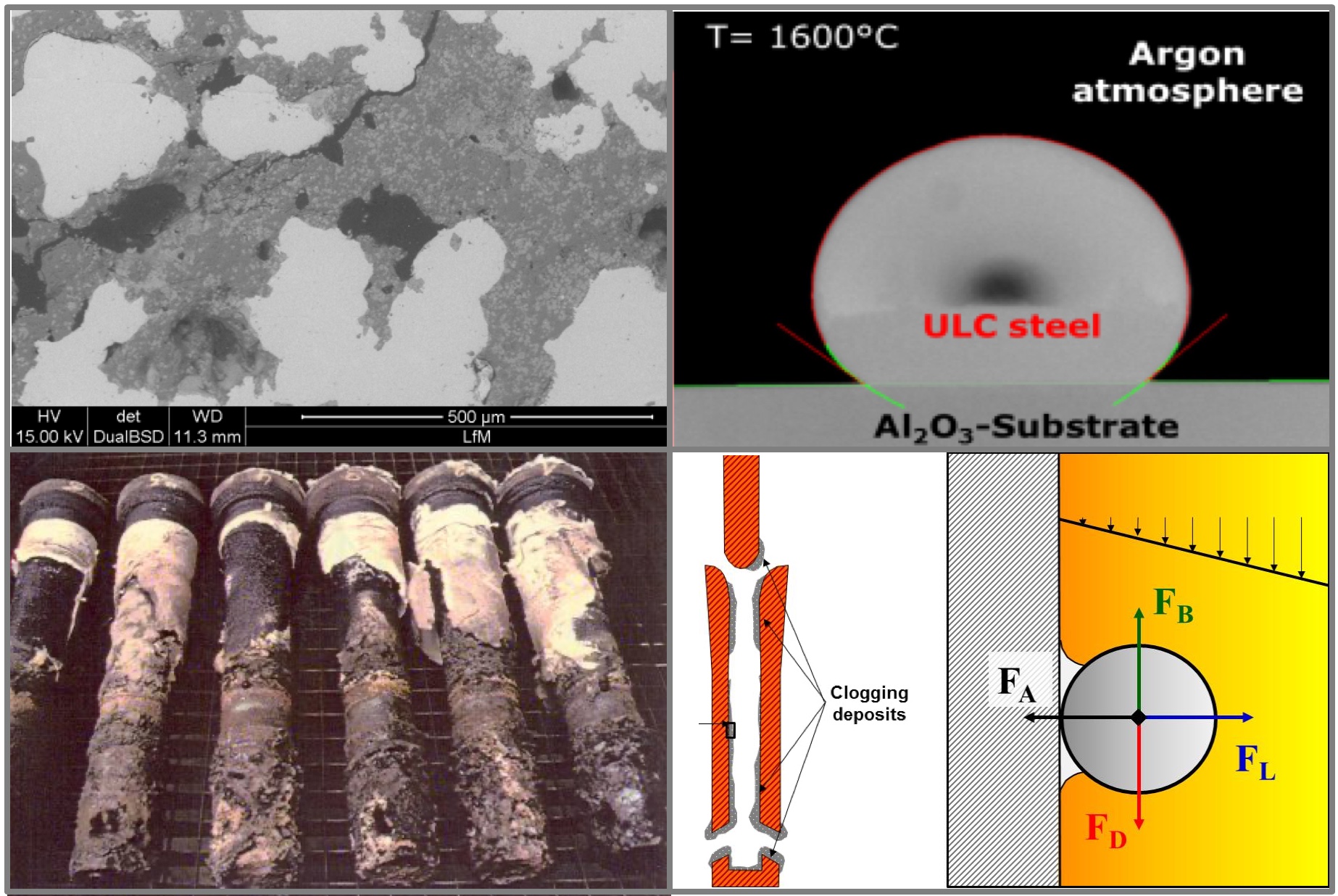

Steel Cleanliness: Inclusions in Steel S - Heat Treat Doctorcom

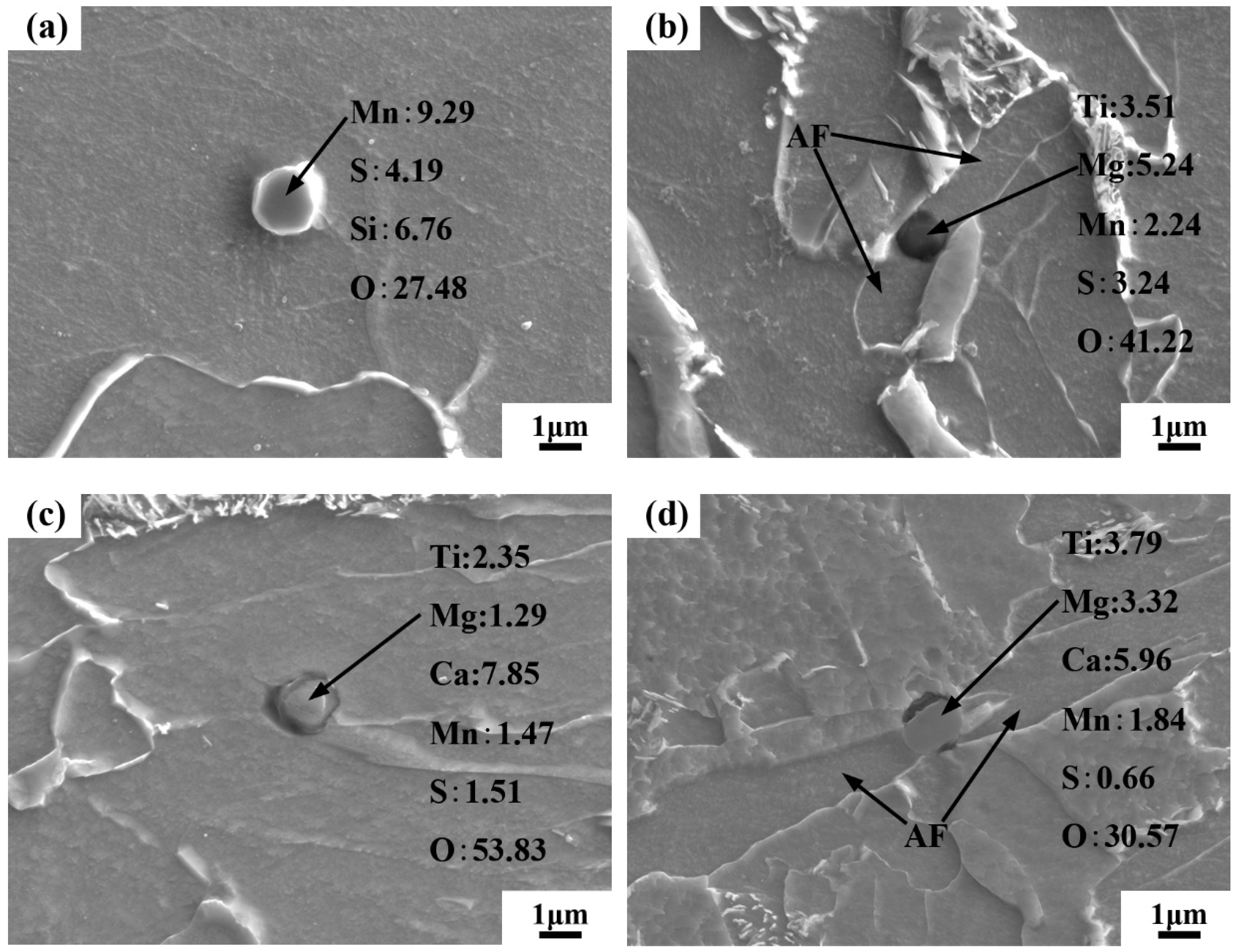

Here’s a brief overview of the more common types of inclusions: 1 Alumina (Al 2O 3) is found in steel in which aluminum has been added typically to control grain size or as a deoxidant It can also be carried into steels from refractories in which case the inclusions tend to be large and isolated |

|

Centenaire de la Revue de Métallurgie

Je sais que la Revue de Métallurgie a entamé des discussions avec d’autres publications dans le but de jeter les bases d’une Revue Technique et de Revues Scientifiques européennes de qualité et j’encourage donc vivement la Revue de Métallurgie à poursuivre dans cette direction ; c’est la meilleure façon de se donner |

|

Inclusion and Special Education - ERIC

to explore how inclusion and special education are two entities that are deeply interwoven through their historical perspectives and evolutionary trajectory Since inclusion and special education is a broad topic and policies and education systems vary across the globe we decided to focus on the context of the United States for this paper |

|

Searches related to inclusion métallurgie filetype:pdf

En effet les signataires ne souhaitent pas que les salariés relevant d’entreprises de la métallurgie d’Ille-et-Vilaine et du Morbihan soient soumis à des rémunérations conventionnelles minimales différentes en fonction de l’effectif des entreprises qui les emploient Article 4 Durée d’application de cet accord |

What are the types of inclusions in steel?

- Manganese sul? de is the most common type of inclusion en- countered. According to analysis based on the steel ingots containing 0.01-0.15% sulfur, the morphology is typically clas- si? ed into three types: a. Type I are silicon-killed steels (or steels incompletely killed with aluminum, zirconium or titanium).

What is the source of nonmetallic inclusions?

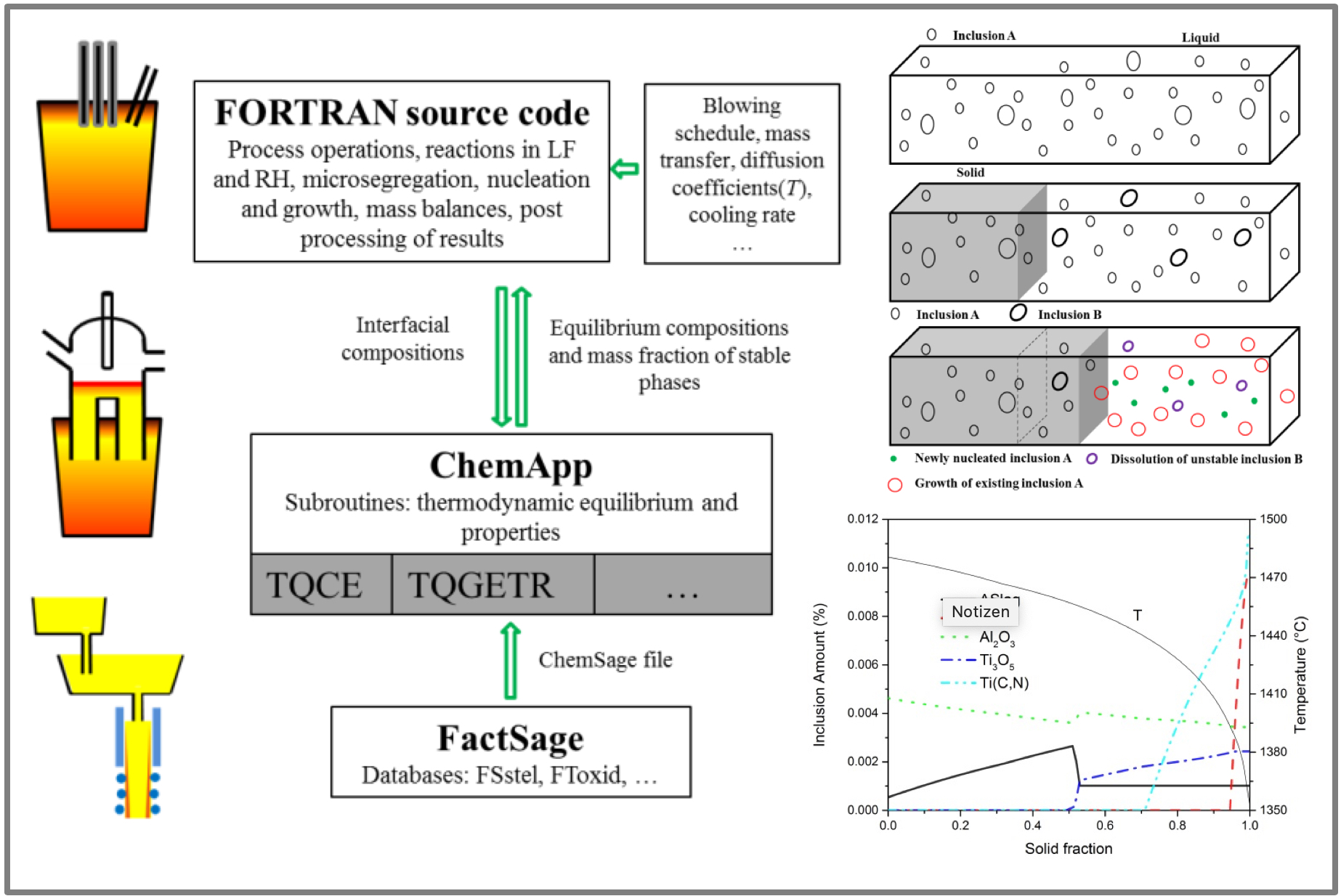

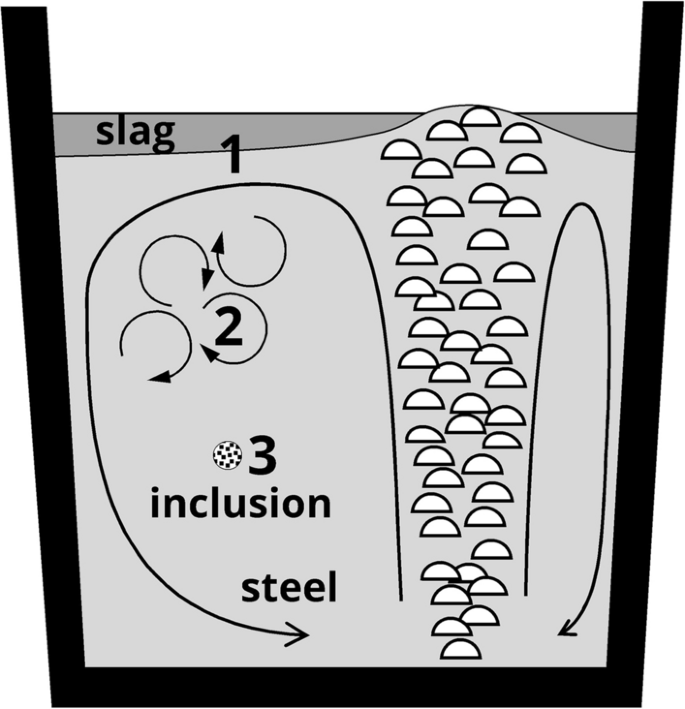

- The steelmaking process (tap, ladle treatment and continuous casting) is the source for most nonmetallic inclusions (Fig. 1), although indigenous (natural) sources, alloy additions and exog- enous (foreign) sources such as refractory or slag also contribute. Most are formed because admixture dissolubility decreases during cooling and consolidation.

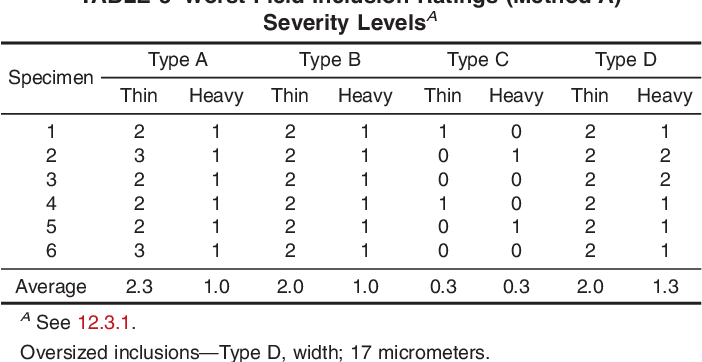

What is the standard test method for inclusions in steel?

- Common test methods include ASTM E 45-05e2 (Standard Test Method for Determining the Inclusion Content of Steel) and ASTM E 2142- 08 (Standard Test Methods for Rating and Classifying Inclusions in Steel Using the Scanning Electron Microscope). Where Do Inclusions Come From?

What are the different methods of inclusion analysis?

- Individual inclusions of- ten consist of more than one type, such as sul? des and silicates, so energy dispersive spectroscopy (EDS) analysis is a useful tool. EDS offers both point analysis and X-ray maps to distinguish among types of inclusions directly, not just by inference from shape. ASTM E 2142 de? nes three methods of inclusion analysis.

|

Inclusions dans les Matériaux Métalliques

23 mar 2007 · Société Française de Métallurgie et de Matériaux d'inclusions sur la qualité et les propriétés mécaniques des alliages, dans un contexte où |

|

Identification rapide des inclusions dans les aciers par la technique

l'Irsid, le CRM (Centre de Recherche Métallurgique à La Revue de Métallurgie- CIT Mars 1997 367 To assess the non-metallic inclusion population in steel |

|

Métallurgie physique - CORE

Rapport du Centre de Recherches Métallurgiques, Liège ÉTUDE DE Les inclusions sont très rares et les précipités à l'intérieur des grains ferri- tiques peu |

|

Doctorat ParisTech TH È SE lÉcole Nationale - Thesesfr

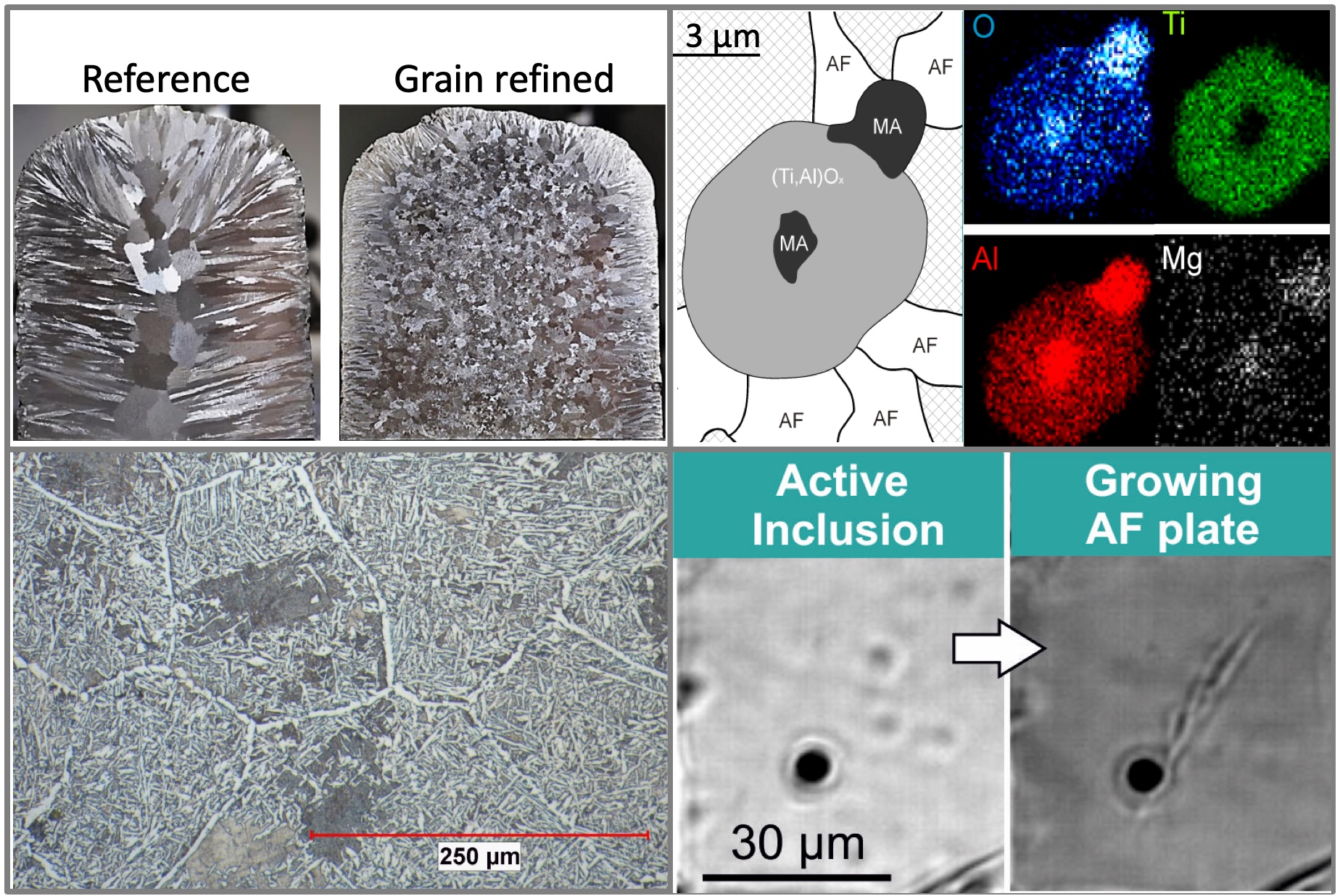

Figure II-9 : Installation de métallurgie en poche [18] Suite à tous ces procédés, l' acier est enfin arrivé dans le moule et peut solidifier Se faisant, les inclusions |

|

Métallurgie physique

Rapport du Centre de Recherches Métallurgiques, Liège ÉTUDE DE Les inclusions sont très rares et les précipités à l'intérieur des grains ferri- tiques peu |

|

Métallurgie du soudage - Eduscol - Ministère de lÉducation nationale

Phénomène provenant uniquement du métal de base (inclusions alignées dans le sens du laminage) Fissuration en ZAT parallèle à la peau des produits laminés |

|

ELABORATION DES METAUX FERREUX (FONTES ET ACIERS)

Le fer et ses alliages sont obtenus par des opérations métallurgiques, qui ont pour but aussi avantageuse, car elle contient peu d'inclusion non métallique |

|

Caractérisation des matériaux par analyse dimage - A3TS

caractéristiques de structures métallurgiques sur une surface d'échantillon ( inclusions) et souvent attaquée chimiquement (taille de grains ) L'analyse |

|

Caj métallurgie du fer et mobilier métallique - RERO DOC

de structure spongieuse encore rempli d'inclusions de scorie et de charbon 5 Chaîne opératoire de la métallurgie du fer (filière directe dans un bas fourneau |

![PDF] Modeling of inclusion evolution in Ladle Metallurgy Furnace PDF] Modeling of inclusion evolution in Ladle Metallurgy Furnace](https://%D1%80%D0%BE%D1%81%D0%B8%D0%BD%D0%BA%D0%B0%D0%BF%D0%BB%D1%8E%D1%81.%D1%80%D1%84/img/din-50602.jpg)

![PDF] INCLUSION CONTROL MODEL IN THE LADLE METALLURGY FURNACE PDF] INCLUSION CONTROL MODEL IN THE LADLE METALLURGY FURNACE](https://reader020.staticloud.net/reader020/html5/20190707/5750a17b1a28abcf0c93deb3/bg1.png)

![PDF] Standard Test Methods for Determining the Inclusion Content PDF] Standard Test Methods for Determining the Inclusion Content](https://media.springernature.com/lw685/springer-static/image/art%3A10.1038%2Fsrep46503/MediaObjects/41598_2017_Article_BFsrep46503_Fig1_HTML.jpg)