30RB/RQ 017-160 - Régulation Pro-Dialog+

30RB/RQ 017-160 - Régulation Pro-Dialog+

Carrier. 30RB/RQ 017-160. Régulation Pro-Dialog+. PRO-DIALOG +. Carrier. AQUASNAP. AQUASNAP. Carrier. \MAINMENUSTATUS. CAPB_T. DEM_LIM. AP. CTRL PHI. INSTOP.

30RB 039-160 / 30RQ 039-160

30RB 039-160 / 30RQ 039-160

Diagnostic rapide des éventuels incidents et de leur historique par la régulation Pro-Dialog+. Les unités Carrier 30RB/RQ sont conçues pour un respect aisé de ...

30RB/30RQ 017-160 Pro-Dialog+ Control

30RB/30RQ 017-160 Pro-Dialog+ Control

The compressors in circuit A are labelled A1. A2 and A3. Those in circuit B are B1 and B2. The following abbreviations are used frequently: CCN. Carrier

AHI Carrier

AHI Carrier

devices fans and of the water heat exchanger water pump for optimum energy efficiency. Pro-Dialog+ interface. \MAINMENUSTATUS. Circuit B Total Capacity.

30RB/30RBY 039-160 “A” Air-Cooled Liquid Chillers

30RB/30RBY 039-160 “A” Air-Cooled Liquid Chillers

To do this consult the 30RB/RQ 017-160 Pro-Dialog+ control manual. 1.2 qualified by Carrier are available via the Carrier spare parts network on request ...

AHI Carrier

AHI Carrier

Pro-Dialog controls compressor start-up needed to maintain the desired heat exchanger entering or leaving water temperature. In cooling mode it controls the

AHI Carrier

AHI Carrier

Touch Pilot Junior Control manual for the 30RB/30RQ 017-160 series. 30RQS on the board refer to the 30RB/RQ Touch Pilot Junior control manual. Other ...

AQUASNAP 30RB / 30RQ 30RBY / 30RQY

AQUASNAP 30RB / 30RQ 30RBY / 30RQY

For the use of the control system refer to the Pro-Dialog + control manual. 30RB-RQ units use a R-410A refrigerant charge. For your information

30RB 039-160 / 30RQ 039-160

30RB 039-160 / 30RQ 039-160

historique par la régulation Pro-Dialog+. Les unités Carrier 30RB/RQ sont conçues pour un respect aisé de ces directives la.

30RB/30RQ 017-040 A 30RBY 017-033 A

30RB/30RQ 017-040 A 30RBY 017-033 A

du système de régulation consulter le Manuel de la régulation Pro-Dialog +. ... Les unités 30RB-RQ utilisent une charge de fluide frigorigène R-410A.

AHI Carrier

AHI Carrier

Pro-Dialog+ combines intelligence with operating simplicity. 30RB/RQ. 017. 021. 026. 033. 040. Power circuit. Nominal power supply. V-ph-Hz.

30RB 039-160

30RB 039-160

PRO-DIALOG +. Model shown is with low-noise option. Air-Cooled Liquid Chillers. 30RB 039-160. Nominal cooling capacity 40-160 kW.

AHI Carrier

AHI Carrier

Pro-Dialog+ combines intelligence with operating simplicity. 30RB/RQ - units with hydronic module ... Source: EU Regulation 813/2013.

30RA/RH “B” 30RY/RYH “B” Régulation PRO-DIALOG

30RA/RH “B” 30RY/RYH “B” Régulation PRO-DIALOG

- Mode CCN: la machine est contrôlée à l'aide de commandes en provenance du réseau CCN (Carrier. Comfort Network). Dans ce cas un câble de communi- cation est

30RBS/30RBSY 039-160 « C »

30RBS/30RBSY 039-160 « C »

Sur le fonctionnement du régulateur se reporter au manuel de régulation Touch Pilot Junior pour unités 30RB/RQ. ... professionnel qualifié.

AQUASNAP 30RB / 30RQ 30RBY / 30RQY

AQUASNAP 30RB / 30RQ 30RBY / 30RQY

For the use of the control system refer to the Pro-Dialog + control manual. 30RB-RQ units are shipped with a full operating charge of refrigerant.

AHI Carrier

AHI Carrier

Touch Pilot Junior Control manual for the 30RB/30RQ 017-160 series 3.5 - Applicable rules for units incorporated into an air duct network .

61WG / 30WG 020-090 Régulation Pro-Dialog+

61WG / 30WG 020-090 Régulation Pro-Dialog+

Pro-Dialog contrôle: • le démarrage des compresseurs pour réguler la boucle d'eau. • les pompes

AQUASNAP30RB / 30RQ30RBY / 30RQY

Installation, operation and maintenance instructionsPRO-DIALOG +

Cop_GB_.indd 113-06-2011 9:12:14

30RB/30RQ30RBY/30RQY

ENGLISH

Air-cooled liquid chillers and reversible cycle air-water heat pump with integrated hydronic module

Cop_GB_.indd 213-06-2011 9:12:14

GB - 1

ENGLISH

30RB/30RQ - 30RBY/30RQY

Air-cooled liquid chillers and reversible air-to-water heat pumps with integrated hydronic module For the use of the control system, refer to the Pro-Dialog + control manual.Contents

PagePhysical data

........................................................................................................................................................................ 2-5

Electrical data

...................................................................................................................................................................... 2-5

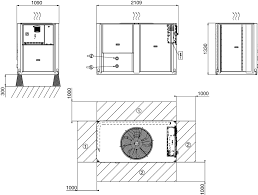

Dimensions and location of hydraulic connections

................................................................................................. 6-8

User interface and main switch

...................................................................................................................................... 9

Clearance for horizontal outlet unit

.............................................................................................................................. 9

Clearance for vertical outlet unit

.................................................................................................................................... 9

General information and hydronic module ............................................................................................................... 10-12

Water connections

............................................................................................................................................................. 12-14

Electrical connections

....................................................................................................................................................... 15

Refrigerant charge

............................................................................................................................................................. 16

Electronic control

............................................................................................................................................................... 16

Start-up ................................................................................................................................................................................. 17

Compressor replacement................................................................................................................................................. 17

Pump replacement

............................................................................................................................................................ 18

Unit protection devices

.................................................................................................................................................... 18-19

Operating limits and operating range

.......................................................................................................................... 19

General maintenance

........................................................................................................................................................ 20

Maintenance ....................................................................................................................................................................... 20

Final recommendations

.................................................................................................................................................... 20

Troubleshooting

................................................................................................................................................................. 21

Start up date _________________________

Equipment sold by:

_________________________________________________Contract No: _________________________________Installed by:

_______________________________________________________Contract No: _________________________________

Site address

____________________________Equipment type and serial No:

30RB ___________________________________________________________________

30RQ ___________________________________________________________________

ELECTRICAL DATA:

Supply voltage

Ph 1: _______________V Ph 2: _______________V Ph 3: ________________VNominal voltage:

_________________________________________V % network voltage ____________________________Current draw

Ph 1: _______________A Ph 2: _______________A Ph 3: _________________AControl circuit voltage:

_____________________________________V Control circuit fuse__________________________AMain circuit breaker rating

________________PHYSICAL DATA

Coil:Plate heat exchanger:

Entering air temp.:

____________________________°C Entering water temp.: _____________________°CLeaving air temp.:

____________________________°C Leaving water temp.: ______________________°CLoss of head (water): ______________________kPa

SAFETY DEVICE SETTING:

High pressure switc

h: cut-out: __________________kPa cut-in: ________________________kPaOil level

_______________________________OPTIONS:

Commissioning engineer

_________________Customer agreement

Name :______________________________________ Date: ___________________________________ Note Complete this start-up list at the time of installation.Start-up check list

128H68-GB.indd 113-06-2011 8:32:42

30RBGB - 2

30RB017 021 026 033

PowerV-ph-Hz 400-3-50

Voltage range

V 340-460

Starting current*

A 75 95 118 118

Maximum power drawn (Vn) **

kW 7,8 9,1 11,0 13,8Rated current***

A 8 12 16 17

Maximum power drawn (Vn) ****

A 13 16 20 24

Maximum power drawn (Vn +/-15%) †

A 15 18 23 27

* Max. starting current within the operation limits (corresponding to the current of locked rotor in the compressor)

** Input power when the unit is at its operation limits (evaporation temperature = 10°C, condensation temperature = 65°C) and at the rated voltage (400 V)

*** The currents shown refer to Eurovent conditions (evaporator water inlet and outlet temperature = 12/7°C with air to the condenser at 35°C)

**** Max. operating current related to the max. input power and rated voltage (400 V) † Max. operating current related to the max. input power and within the range 340-460 VTable II: Electrical data - Model RB

30RB017 021 026 033

Operating weight

with hydronic moduleKg 189 208 255 280

without hydronic moduleKg 173 193 237 262

Refrigerant charge R-410A

Kg 5,5 6,4 5,8 8,6

Compressor

One scroll compressor

Evaporator

One plate heat exchanger

Net water volume

l 1,52 1,9 1,71 2,28Water connections (MPT gas)

inches 1 1 1-1/4 1-1/4Maximum water pressure

kPa 1000 1000 1000 1000 (unit without hydronic module)Maximum water pressure

kPa 400 400 400 400 (unit with hydronic module)Hydronic module

Pump, mesh ?lter, expansion tank, ?ow switch, pressure gauges, automatic air purge valve and drain plug and safety valve.

PumpOne single-speed pump

Water inlet connection (MPT gas)

inches 1-1/4 1-1/4 1-1/4 1-1/4Water outlet connection (MPT gas)

inches 1 1 1-1/4 1-1/4Closed expansion tank water volume

l 5 5 8 8Pre-charge of expansion vessel

bar 1,5 1,5 1,5 1,5Water ?ll system (option)

Inlet/outlet diameter (MPT gas)

inches 1/2 1/2 1/2 1/2Condenser

One, copper tubes and aluminium ?ns

Fan Two,axial type with two speeds Two-speed axial typeDiameter

mm 495 495 710 710No. of blades

3 3 7 7

Air ?ow (high speed)

l/s 2212 2212 3530 3530Fan speed (high speed)

g/min 870 870 900 900Table I: Physical data - Model RB

Physical data and electrical data - Model RB

128H68-GB.indd 213-06-2011 8:32:42

30RQGB - 3

ENGLISH

30RQ017 021 026 033

PowerV-ph-Hz 400-3-50

Voltage range

V 340-460

Starting current*

A 75 95 118 118

Maximum power drawn (Vn) **

kW 7,8 9,1 11,0 13,8Nominal current drawn***

kW 8 12 16 17Maximum power drawn (Vn) ****

A 13 16 20 24

Maximum power drawn (Vn +/-15%) †

A 15 18 23 27

* Max. starting current within the operation limits (corresponding to the current of locked rotor in the compressor)

** Input power when the unit is at its operation limits (evaporation temperature = 10°C, condensation temperature = 65°C) and at the rated voltage (400 V)

*** The currents shown refer to Eurovent conditions (evaporator water inlet and outlet temperature = 12/7°C with air to the condenser at 35°C)

**** Max. operating current related to the max. input power and rated voltage (400 V) † Max. operating current related to the max. input power and within the range 340-460 VTable II: Electrical data - Model RQ

30RQ017 021 026 033

Operating weight

with hydronic moduleKg 206 223 280 295

without hydronic moduleKg 191 208 262 277

Refrigerant charge R-410A

Kg 6,4 7,7 7,6 9,5

Compressor

One scroll compressor

Evaporator

One plate heat exchanger

Net water volume

l 1,52 1,9 2,28 2,85Water connections (MPT gas)

inches 1 1 1-1/4 1-1/4Maximum water pressure

kPa 1000 1000 1000 1000 (unit without hydronic module)Maximum water pressure

kPa 400 400 400 400 (unit with hydronic module)Hydronic module

Pump, mesh ?lter, expansion tank, ?ow switch, pressure gauges, automatic air purge valve and drain plug and safety valve.

PumpOne single-speed pump

Water inlet connection (MPT gas)

inches 1-1/4 1-1/4 1-1/4 1-1/4Water outlet connection (MPT gas)

inches 1 1 1-1/4 1-1/4Closed expansion tank water volume

l 5 5 8 8Pre-charge of expansion vessel

bar 1,5 1,5 1,5 1,5Water ?ll system (option)

Inlet/outlet diameter (MPT gas)

inches 1/2 1/2 1/2 1/2Condenser

One, copper tubes and aluminium ?ns

Fan Two,axial type with two speeds Two-speed axial typeDiameter

mm 495 495 710 710No. of blades

3 3 7 7

Air ?ow (high speed)

l/s 2217 1978 3530 3530Fan speed (high speed)

g/min 870 870 900 900Table I: Physical data - Model RQ

Physical data and electrical data - Model RQ

128H68-GB.indd 313-06-2011 8:32:42

30RBYGB - 4

30RBY017 021 026 033

PowerV-ph-Hz 400-3-50

Voltage range

V 360 - 440

Starting current*

A 75 95 118 118

Maximum power drawn (Vn) **

kW 8,0 9,3 11,2 14,0Rated current***

W 8 12 20 21

Maximum power drawn (Vn) ****

A 13 16 20 24

Maximum power drawn (Vn +/-15%) †

A 15 18 23 27

* Max. starting current within the operation limits (corresponding to the current of locked rotor in the compressor)

** Input power when the unit is at its operation limits (evaporation temperature = 10°C, condensation temperature = 65°C) and at the rated voltage (400 V)

*** The currents shown refer to Eurovent conditions (evaporator water inlet and outlet temperature = 12/7°C with air to the condenser at 35°C)

**** Max. operating current related to the max. input power and rated voltage (400 V) † Max. operating current related to the max. input power and within the range 360-440 VTable II: Electrical data - Model RBY

30RBY017 021 026 033

Operating weight**

with hydronic moduleKg 209 228 255 280

without hydronic moduleKg 193 213 237 262

Refrigerant charge R-410A

Kg 5,5 6,4 5,8 8,6

Compressor

One scroll compressor

Evaporator

One plate heat exchanger

Net water volume

l 1,52 1,9 1,71 2,28Water connections (MPT gas)

inches 1 1 1-1/4 1-1/4Maximum water pressure

kPa 1000 1000 1000 1000 (unit without hydronic module)Maximum water pressure

kPa 400 400 400 400 (unit with hydronic module)Hydronic module

Pump, mesh ?lter, expansion tank, ?ow switch, pressure gauges, automatic air purge valve and drain plug and safety valve.

PumpOne single-speed pump

Water inlet connection (MPT gas)

inches 1-1/4 1-1/4 1-1/4 1-1/4Water outlet connection (MPT gas)

inches 1 1 1-1/4 1-1/4Closed expansion tank water volume

l 5 5 8 8Pre-charge of expansion vessel

bar 1,5 1,5 1,5 1,5Water ?ll system (option)

Inlet/outlet diameter (MPT gas)

inches 1/2 1/2 1/2 1/2Condenser

One, copper tubes and aluminium ?ns

Fan Two radial fans with backward blades One axial fanDiameter

mm 495 495 710 710No. of blades

3 3 7 7

Outlet static pressure

Pa 80 80 80 80

Air ?ow (high speed)

l/s 2212 2212 3530 3530Fan speed (high speed)

g/min 870 870 900 900Table I: Physical data - Model RBY

Physical data and electrical data - Model RBY

128H68-GB.indd 413-06-2011 8:32:43

30RQYGB - 5

ENGLISH

30RQY017 021 026 033

PowerV-ph-Hz 400-3-50

Voltage range

V 360 - 440

Starting current*

A 75 95 118 118

Maximum power drawn (Vn) **

kW 8,0 9,3 11,2 14,0Nominal current drawn***

W 8 12 20 21

Maximum power drawn (Vn) ****

A 13 16 20 24

Maximum power drawn (Vn +/-15%) †

A 15 18 23 27

* Max. starting current within the operation limits (corresponding to the current of locked rotor in the compressor)

** Input power when the unit is at its operation limits (evaporation temperature = 10°C, condensation temperature = 65°C) and at the rated voltage (400 V)

*** The currents shown refer to Eurovent conditions (evaporator water inlet and outlet temperature = 12/7°C with air to the condenser at 35°C)

**** Max. operating current related to the max. input power and rated voltage (400 V) † Max. operating current related to the max. input power and within the range 360-440 VTable II: Electrical data - Model RQY

30RQY017 021 026 033

Operating weight**

with hydronic moduleKg 226 243 280 295

without hydronic moduleKg 211 228 262 277

Refrigerant charge R-410A

Kg 6,4 7,7 7,6 9,5

Compressor

One scroll compressor

Evaporator

One plate heat exchanger

Net water volume

l 1,52 1,9 2,28 2,85Water connections (MPT gas)

inches 1 1 1-1/4 1-1/4Maximum water pressure

kPa 1000 1000 1000 1000 (unit without hydronic module)Maximum water pressure

kPa 400 400 400 400 (unit with hydronic module)Hydronic module

Pump, mesh ?lter, expansion tank, ?ow switch, pressure gauges, automatic air purge valve and drain plug and safety valve.

PumpOne single-speed pump

Water inlet connection (MPT gas)

inches 1-1/4 1-1/4 1-1/4 1-1/4Water outlet connection (MPT gas)

inches 1 1 1-1/4 1-1/4Closed expansion tank water volume

l 5 5 8 8Pre-charge of expansion vessel

bar 1,5 1,5 1,5 1,5Water ?ll system (option)

Inlet/outlet diameter (MPT gas)

inches 1/2 1/2 1/2 1/2Condenser

One, copper tubes and aluminium ?ns

Fan Two radial fans with backward blades One axial fanDiameter

mm 495 495 710 710No. of blades

3 3 7 7

quotesdbs_dbs23.pdfusesText_29[PDF] 30RA/RY - 30RH/RYH Régulation PRO-DIALOG - Carrier

[PDF] 30RA/RY - 30RH/RYH Régulation PRO-DIALOG - Carrier

[PDF] OPERATION AND SERVICE MANUAL SUPRA 750Mt_, 850Mt_

[PDF] Québec Métiers d 'avenirpdf

[PDF] Dares Analyses 2016-056 - Les jeunes en emploi d 'avenir

[PDF] Declaración de Derechos ( Bill of Rigths ) de los Estados Unidos de

[PDF] Propuesta de Servicios Profesionales

[PDF] distance carte échelle = distance réelle - Académie de Nancy-Metz

[PDF] Demande de Carte de réduction - Oncf

[PDF] Conditions générales CARTE FNAC + - Resilierfr

[PDF] RÉPUBLIQUE TOGOLAISE

[PDF] carte administrative idf - Driea

[PDF] Inscriptions administratives 2017/2018 - L 'Université Paris Descartes

[PDF] Images correspondant ? carte afrique avant colonisation filetype:pdf