BTEC Assignment Brief

BTEC Assignment Brief

You will produce a sample of ethyl ethanoate and test its purity. You will have to compare your laboratory technique with the industrial process used by the

Specification - Pearson BTEC Level 3 National Extended Diploma in

Specification - Pearson BTEC Level 3 National Extended Diploma in

investigate the different methods for testing the purity of the products. o industrial scale – from ethanol and ethanoic acid (for ethyl ethanoate) o ...

8-Synthesis-of-Aspirin.pdf

8-Synthesis-of-Aspirin.pdf

The collected aspirin will be tested for its purity using FeCl3 (aq). Iron (III) ion reacts with phenols to form a purple complex. Salicylic acid contains a

GENERAL TESTS PROCESSES AND APPARATUS

GENERAL TESTS PROCESSES AND APPARATUS

Purity of crude drug (17:3) at a rate of not more than 5 mL per minute ... ethyl acetate and water (4:4:3) as the developing solvent: the standard solution ...

UK Standard Industrial Classification of Economic Activities 2007

UK Standard Industrial Classification of Economic Activities 2007

This group includes the manufacture of measuring testing and navigating equipment for various industrial and non-industrial testing of composition and purity ...

Aspirin

Aspirin

to test for purity. ... s Access to a few iodine crystals (three or four per experiment is enough) s Samples for testing s Ethyl ethanoate as chromatography ...

Ethanol to Ethyl Acetate

Ethanol to Ethyl Acetate

20 May 2019 The ethyl acetate produced has a weight purity of 99.8% meeting market specifications. This process makes use of three main unit operations

Student Safety Sheets

Student Safety Sheets

testing. Limited amounts of Red Bull or similar

Practical handbook

Practical handbook

To test the purity of an organic solid by measuring its melting point t) As the ethyl ethanoate vapours start to carry over and condense record the ...

Investigating Esters

Investigating Esters

Plan to prepare a sample of butyl ethanoate ethyl ethanoate or methyl ethanoate. Unknown author

Integration of the Process for Production of Ethyl Acetate by an

Integration of the Process for Production of Ethyl Acetate by an

17 Aug 2021 Ethyl acetate (EA) in the chemical industry is obtained mainly by the ... This is a particular problem when high purity ethyl acetate is.

High Purity Ethyl Acetate Production with a Batch Reactive

High Purity Ethyl Acetate Production with a Batch Reactive

22 Oct 2010 on the industrial grade ethyl acetate production operating in a batch mode. ... control problem which is formulated to determine an optimal.

BTEC Assignment Brief

BTEC Assignment Brief

B: Explore the manufacturing techniques and testing methods for an organic liquid Prepare a sample of ethyl ethanoate and test its purity.

Q3C (R6) Step 5 - impurities: guideline for residual solvents

Q3C (R6) Step 5 - impurities: guideline for residual solvents

9 Aug 2019 of the solvent for the synthesis of drug substance may enhance the yield or determine characteristics such as crystal form

Aspirin

Aspirin

Ethyl ethanoate is highly flammable and the vapour may irritate the eyes and Chromatography techniques are used a great deal in industry because they ...

Higher Nationals

Higher Nationals

paracetamol antifebrin; a liquid organic compound eg ethyl ethanoate

GENERAL TESTS PROCESSES AND APPARATUS

GENERAL TESTS PROCESSES AND APPARATUS

microscopic examination purity test

8-Synthesis-of-Aspirin.pdf

8-Synthesis-of-Aspirin.pdf

The collected aspirin will be tested for its purity using FeCl3 (aq). Iron (III) ion reacts with phenols to form a purple complex. Salicylic acid contains a

Aspirin

Aspirin

Ethyl ethanoate is volatile highly flammable and the vapour may irritate the eyes and respiratory system. Chemical tests for purity.

rification_and_testing_of_ethyl_ethanoate_in_the_laboratorydocx

rification_and_testing_of_ethyl_ethanoate_in_the_laboratorydocx

High Purity Ethyl Acetate Production with a Batch Reactive Distillation Column using Dynamic Optimization Strategy Abstract—Ethyl acetate with the minimum purity of 85 0 by mole is inevitably needed as an active solvent used in a wide range of applications across many industries

Is industrial manufacture of ethyl ethanoate preferred method of production?

- The gas produced should not be smelled directly instead be wafted to avoid interaction with the respiratory system. Conclusion and evaluations In conclusion, industrial manufacture of ethyl ethanoate is more preferred method of production, as large amount of output of the products is obtained.

What are ethyl ethanoate & ethanol ester?

Esters can be made from carboxylic acids and alcohols. This is discussed in detail on another page; in general terms, the two combine together, losing a molecule of water in the process. Consider a very simple ester such as ethyl ethanoate. The figure below shows its formation from ethanoic acid and ethanol.

What is the maximum purity of ethyl acetate?

It is normally produced by the esterification of ethanol and acetic acid. Due to the equilibrium limitation, it has been reported that the ethyl acetate with the maximum purity of 52.0% can be obtained in a batch reactor. To achieve higher purity, further purification unit is added with the use of some energy.

What does ethylethanoate smell like?

Abundance acid and alcohol bothdissolve and are tucked securely away under the ester layer. Little esters like ethylethanoate smell like ordinary natural solvents (ethyl ethanoate is a common solventin, for example, glues). As the esters get greater, the smells tend towards artificialfruit flavouring - "pear drops", for example.

Abstract - Ethyl acetate with the minimum purity of 85.0% by mole is inevitably needed as an active solvent used in a wide range of applications across many industries. It is normally produced by the esterification of ethanol and acetic acid. Due to the equilibrium limitation, it has been reported that the ethyl acetate with the maximum purity of 52.0% can be obtained in a batch reactor. To achieve higher purity, further purification unit is added with the use of some energy. Alternatively, to overcome the limitation, a batch reactive distillation column, combining the reaction and separation into a single stage, is proposed. The ethyl acetate is always distilled and withdrawn out the reaction zone and the equilibrium is shifted to the right. The reactant conversion is then improved. Therefore, the objective of this work is to study an approach to produce ethyl acetate with the purity of 90.0% by mole by a batch reactive distillation column. Based on open loop simulations, the distillation with constant reflux ratio cannot achieve the product specification. Thus, dynamic optimization strategy is proposed to handle this problem. The optimization problem is formulated to maximize the weight of distillate product for a given product specification, reboiler heat duty, and batch operating time. For the process safety - preventing the dried column and fractured, minimum reflux ratio must be determined in advance and then an optimal reflux profile is calculated to achieve optimal product yield. Simulation results show that 90.0% purity of distillate product can be produced by the dynamic optimization programming with two or more time intervals. Besides, the higher time intervals results in the higher distillate product. Index Terms - batch reactive distillation, dynamic optimization, high purity ethyl acetate, optimal control I. I

Abstract - Ethyl acetate with the minimum purity of 85.0% by mole is inevitably needed as an active solvent used in a wide range of applications across many industries. It is normally produced by the esterification of ethanol and acetic acid. Due to the equilibrium limitation, it has been reported that the ethyl acetate with the maximum purity of 52.0% can be obtained in a batch reactor. To achieve higher purity, further purification unit is added with the use of some energy. Alternatively, to overcome the limitation, a batch reactive distillation column, combining the reaction and separation into a single stage, is proposed. The ethyl acetate is always distilled and withdrawn out the reaction zone and the equilibrium is shifted to the right. The reactant conversion is then improved. Therefore, the objective of this work is to study an approach to produce ethyl acetate with the purity of 90.0% by mole by a batch reactive distillation column. Based on open loop simulations, the distillation with constant reflux ratio cannot achieve the product specification. Thus, dynamic optimization strategy is proposed to handle this problem. The optimization problem is formulated to maximize the weight of distillate product for a given product specification, reboiler heat duty, and batch operating time. For the process safety - preventing the dried column and fractured, minimum reflux ratio must be determined in advance and then an optimal reflux profile is calculated to achieve optimal product yield. Simulation results show that 90.0% purity of distillate product can be produced by the dynamic optimization programming with two or more time intervals. Besides, the higher time intervals results in the higher distillate product. Index Terms - batch reactive distillation, dynamic optimization, high purity ethyl acetate, optimal control I. I NTRODUCTION

Ethyl acetate, available in 3 grades: 85.0-88.0%, 99.0%, and 99.5%, is used as an active solvent in industrial lacquers and surface coating resins. It is also used as an extraction solvent in the production of pharmaceuticals and food, and as a carrier solvent for herbicides [1].The ethyl acetate is normally produced by the

Manuscript submitted March 3, 2010. This work was financial supported by the Thailand Research Fund through the Royal Golden Jubilee Ph.D.Program under Grant PHD/0183/2548.

P. Kittisupakorn is with the Department of Chemical Engineering, Chulalongkorn University, Bangkok 10330 Thailand (corresponding author, tel: +66-2218-6892; fax: +66-2218-6877; e-mail: Paisan.k@chula.ac.th). K. Konakom and A. Saengchan are the doctoral students of the Department of Chemical Engineering, Chulalongkorn University, Bangkok,10330 Thailand.

I. M. Mujtaba is with the School of Engineering, Design & Technology,University of Br

adford, Bradford BD7 1DP, UK. esterification reaction of ethanol and acetic acid. Helminen et al. [2] reported that the ethyl acetate with 52.0% purity maximum can be occurred in a batch reactor. The product purity is very low because of the equilibrium limitation resulting in the need of further purification. Therefore, the combination of reaction and separation processes into a single unit like reactive distillation column is used. However, there has been only very few papers published on the industrial grade ethyl acetate production operating in a batch mode. One literature has proposed a nonlinear state estimator and control system to achieve the ethyl acetate of93.44% by mole after operating under total reflux for 25 hrs

[3]. Other literatures have presented the production of ethyl acetate using a batch reactive distillation column, focused on simulation, optimization [4], [5], and control of the distillate product at a maximum of 80.0% by mole of ethyl acetate [6], [7]. These works have shown the difficulty to achieve the industrial grade ethyl acetate in a shift of 8 hrs. In this work, the production of industrial grade ethyl acetate of 90.0% by mole by 8 hrs using a conventional batch reactive distillation column is proposed. A dynamic optimization strategy is incorporated to solve an optimal control problem which is formulated to determine an optimal reflux ratio. The objective function of the control problem is to maximize the weight of dis tillate product with reboiler heat duty of 50 MJ/hr.II. PROCESS DESCRIPTION

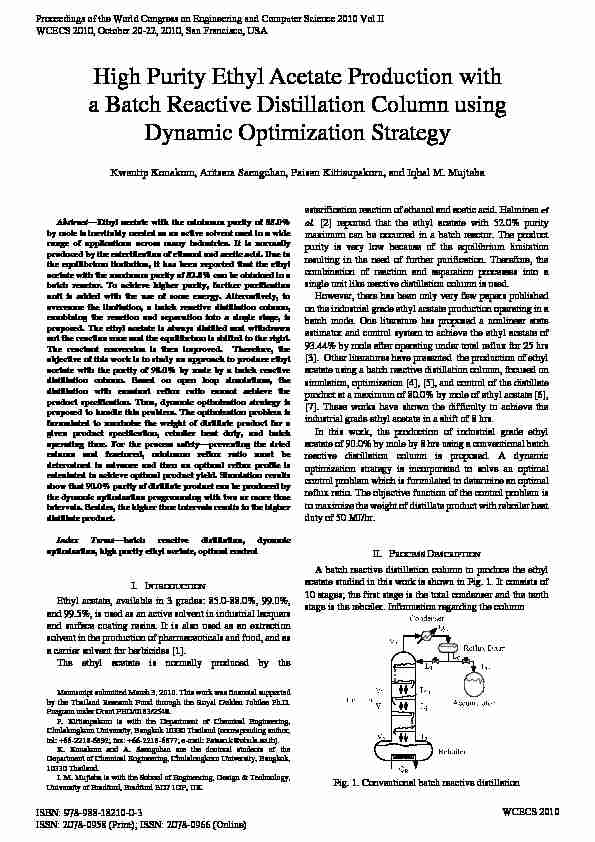

A batch reactive distillation column to produce the ethyl acetate studied in this work is shown in Fig. 1. It consists of10 stages; the first stage is the total condenser and the tenth

stage is the reboiler. Information regarding the column Fig. 1. Conventional batch reactive distillation

High Purity Ethyl Acetate Production with

a Batch Reactive Distillation Column usingDynamic Optimization Strategy

Kwantip Konakom, Aritsara Saengchan, Paisan Kittisupakorn, and Iqbal M. Mujtaba Proceedings of the World Congress on Engineering and Computer Science 2010 Vol II

WCECS 2010, October 20-22, 2010, San Francisco, USAISBN: 978-988-18210-0-3 ISSN: 2078-0958 (Print); ISSN: 2078-0966 (Online)WCECS 2010Table I. Column specifications

System: Acetic acid/ethanol/ethyl acetate/water

Total feed charge,

10H: 5.0 kmol

Feed composition (mole fraction): 0.45/0.45/0.0/0.1Column holdup

Reflux drum holdup:

0.1quotesdbs_dbs7.pdfusesText_5[PDF] tex's french grammar prepositions with places answers

[PDF] tex's french grammar pronominal verbs answers

[PDF] tex's french grammar pronoun en answers

[PDF] tex's french grammar pronoun y answers

[PDF] tex's french grammar questions with subject/verb inversion answers

[PDF] texas ant identification chart

[PDF] texas area code map

[PDF] texas attorney general child support chart 2019

[PDF] texas blue 2024

[PDF] texas bureau of prisons

[PDF] texas carpenter ants

[PDF] texas certificate of conversion

[PDF] texas climate

[PDF] texas code of criminal procedure chapter 15