AMPLIFICADORES PARA ACELEROMETROS Since 1959

AMPLIFICADORES PARA ACELEROMETROS Since 1959

Connector Binder 713 UNF 10-32 UNF 10-32. Weight. 165 gr. 150 gr. 150 gr. Height. 36 mm. 42 mm. 42 mm. Diameter. 32 mm. 50 mm. 50 mm. Model. KS76(a)(1). KS77(a)

Piezoelectric Charge Accelerometer Types 4384 and 4384-V (BP

Piezoelectric Charge Accelerometer Types 4384 and 4384-V (BP

10 – 32 UNF-2B × 3.2 mm threaded hole. Mounting Torque. Max. Nm (lbf∙in). 3.5 Set screw 10 – 32 UNF × 1/ 2″ (12.8 mm). YQ-2962. Set screw

Piezoelectric Charge Accelerometer Types 4382 and 4382-V (BP

Piezoelectric Charge Accelerometer Types 4382 and 4382-V (BP

10 – 32 UNF length 5.3 mm. YJ-0216. Beeswax for mounting. YP-0080. Probe with 10 – 32 UNF-2B × 3.2 mm threaded hole. Mounting Torque. Max. Nm (lbf∙in). 3.5 ...

Piezoelectric Charge Accelerometer Types 4381 and 4381-V (BP

Piezoelectric Charge Accelerometer Types 4381 and 4381-V (BP

10 – 32 UNF-2B × 3.2 mm threaded hole. Mounting Torque. Max. Nm (lbf∙in). 3.5 Set screw 10 – 32 UNF × 1/ 2″ (12.8 mm). YQ-2962. Set screw

Piezoelectric Charge Accelerometer Types 4371 and 4371-V (BP

Piezoelectric Charge Accelerometer Types 4371 and 4371-V (BP

10 – 32 UNF length 13 mm. YQ-2960. Set screw

Product Data: Piezoelectric Charge Accelerometer Types 4383 and

Product Data: Piezoelectric Charge Accelerometer Types 4383 and

Probe with sharp tip 10 – 32 UNF. YP-0150. Insulated stud

Product data: Lateral Modal Exciter Stands - UA 1607 UA 1608

Product data: Lateral Modal Exciter Stands - UA 1607 UA 1608

200mm diameter 2.5mm. Ten fastening screws. UA1597. Five push/pull steel stingers. Content: Ten adaptors

Product Data: Piezoelectric Charge Accelerometer Types 4375 and

Product Data: Piezoelectric Charge Accelerometer Types 4375 and

10–32 UNF connectors 250 °C (482 °F). DB-0757. Cementing stud

Piezoelectric Charge Accelerometer Types 4370 and 4370-V(BP

Piezoelectric Charge Accelerometer Types 4370 and 4370-V(BP

10 – 32 UNF length 5.3 mm. YJ-0216. Beeswax for mounting. YP-0080. Probe with sharp tip

Metric Landscape AG Catalogue 2020_Layout 1

Metric Landscape AG Catalogue 2020_Layout 1

4.5 mm Barb. 10-32 UNF. Thread. 4.5 mm Barb 4.5 mm Barb. 1/2” NPT/F. Thread. Dimensions. Assembled. Height. 24 mm. 24 mm. 152 mm. 152 mm. 30 mm. Width. 20 mm.

Product Data: Piezoelectric Charge Accelerometer Types 4384 and

Product Data: Piezoelectric Charge Accelerometer Types 4384 and

10 – 32 UNF-2A top connector and a 10 – 32 UNF-2B threaded hole for mounting. 10 – 32 UNF threaded steel stud length 12.7 mm. Type 4384-V.

Tap Drill Sizes

Tap Drill Sizes

Minor Diameter. Tap Drill Diameter (Cutting Tap). UNC. UNF. UNEF 16 TAP DRILL SIZES - METRIC THREAD. Size. Pitch ... #10 - 32 UNF .2008. 5.10.

TAP DRILL SIZES INCH / METRIC EQUIVALENT

TAP DRILL SIZES INCH / METRIC EQUIVALENT

#10-32 UNC/UNF CUT TAPS - Special Percentage of Thread Requirements ... Drill Size (mm) = Basic Major Diameter - pitch x desired % of thread*.

Tubing and Fittings Quick Reference - Metric & Inch

Tubing and Fittings Quick Reference - Metric & Inch

8 Metric Fittings. 14 Tubing. QB Series – Threaded Inch Fittings. Example: QB Series T style connector with 10-32 UNF thread and ¼ inch tube connection.

Product Data: Piezoelectric Charge Accelerometer Types 4370 and

Product Data: Piezoelectric Charge Accelerometer Types 4370 and

a 10 – 32 UNF-2A top connector and a 10 – 32 UNF-2B threaded hole for mounting. 10 – 32 UNF threaded steel stud length 12.7 mm. Type 4370-V.

HS-AS Studs

HS-AS Studs

10-32 UNF x 9.5 mm Long Male Hex Socket Drive. M10 Male x 1.50 Stop & Slot x 11.5mm Long. ¼”-28 UNF Male Stop & Slot x 11.5mm Long.

AMPLIFICADORES PARA ACELEROMETROS Since 1959

AMPLIFICADORES PARA ACELEROMETROS Since 1959

Connector Binder 713 UNF 10-32 UNF 10-32. Weight. 165 gr. 150 gr. 150 gr. Height. 36 mm. 42 mm. 42 mm. Diameter. 32 mm. 50 mm. 50 mm. Model. KS76(a)(1).

Product Data: Piezoelectric Charge Accelerometer Types 4382 and

Product Data: Piezoelectric Charge Accelerometer Types 4382 and

AO-0038: Low-noise coaxial cable with 10 – 32 UNF connectors length 1.2 m. • 10 – 32 UNF threaded steel stud

Gaugeable Tube Fittings and Adapter Fittings (MS-01-140;rev_AF

Gaugeable Tube Fittings and Adapter Fittings (MS-01-140;rev_AF

10-32 Thread. M5 × 0.8 Thread

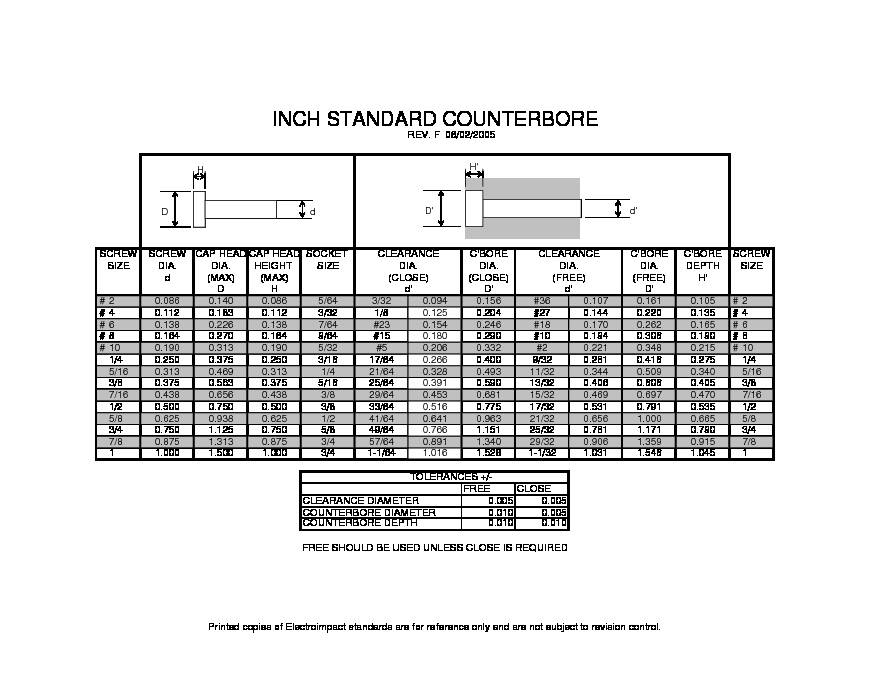

INCH STANDARD COUNTERBORE

INCH STANDARD COUNTERBORE

04-Nov-2015 0.394 8.0 mm. 10.5 0.413 16.5 0.650 11.40 0.449 17.40 0.685 11.0 0.433 M 10. M 12. 0.472. 18.0 0.709. 12.0. 0.472 10.0 mm 12.5 0.492 18.5 ...

REV. F 06/02/2005

SCREWSCREWCAP HEADCAP HEADSOCKET CLEARANCEC'BORECLEARANCEC'BOREC'BORESCREWSIZEDIA.DIA.HEIGHT SIZEDIA.DIA.DIA.DIA.DEPTHSIZE

d(MAX)(MAX)(CLOSE)(CLOSE)(FREE)(FREE)H'DHd'D'd'D'

TOLERANCES +/-

FREECLOSE

CLEARANCE DIAMETER0.0050.005

COUNTERBORE DIAMETER0.0100.005

COUNTERBORE DEPTH0.0100.010

FREE SHOULD BE USED UNLESS CLOSE IS REQUIRED

INCH STANDARD COUNTERBORE

D H dD' H' d'Printed copies of Electroimpact standards are for reference only and are not subject to revision control.

REV. H 06/02/2005

SCREWSCREWCAP HEADCAP HEADSOCKET CLEARANCEC'BORECLEARANCEC'BOREC'BORESCREW SIZEDIA.DIA. (MAX)HEIGHT (MAX)SIZEDIA. (CLOSE)DIA. (CLOSE)DIA. (FREE)DIA. (FREE)DEPTHSIZE dDHd'D'd'D'H' inmminmminmminmminmminmminmmin M20.0793.80.1502.00.0791.5 mm2.20.0874.00.1572.500.0984.300.1692.50.098M2 M2.50.0984.50.1772.50.0982.0 mm2.70.1064.70.1853.000.1185.000.1973.00.118M2.5 M30.1185.50.2173.00.1182.5 mm3.50.1386.00.2363.750.1486.250.2463.50.138M3 M40.1577.00.2764.00.1573.0 mm4.50.1777.50.2954.900.1937.900.3114.50.177M4 M50.1978.50.3355.00.1974.0 mm5.50.2179.00.3545.900.2329.400.3705.50.217M5 M60.23610.00.3946.00.2365.0 mm6.50.25610.50.4137.000.27611.000.4337.00.276M6 M80.31513.00.5128.00.3156.0 mm8.50.33513.50.5319.200.36214.200.5599.00.354M8 M100.39416.00.63010.00.3948.0 mm10.50.41316.50.65011.400.44917.400.68511.00.433M10 M120.47218.00.70912.00.47210.0 mm12.50.49218.50.72813.500.53119.500.76813.00.512M12 M160.63024.00.94516.00.63014.0 mm17.00.66925.00.98418.000.70926.001.02418.00.709M16 M200.78730.01.18120.00.78717.0 mm21.00.82731.01.22022.500.88632.501.28022.00.866M20 M240.94536.01.41724.00.94519.0 mm25.00.98437.01.45726.701.05138.701.52426.01.024M24 M301.18145.01.77230.01.18122.0 mm31.01.22046.01.81133.001.29948.001.89032.01.260M30 NOTE: " FREE SIZES " AND M2.0 AND M2.5 THREAD PITCHES SHOULD ALWAYS BE SPECIFIED, ARE NOT McMASTER CARR STANDARD CUTTING TOOLSBUT WHEN METRIC THREADS ARE SPECIFIED WITHOUT A PITCH, FREE SHOULD BE USED UNLESS CLOSE IS REQUIREDTHE FOLLOWING PITCHES ARE TO BE USED:TOLERANCES +/- M 2X .40M 6X 1.0M 16X 2.0

FREECLOSEM 2.5X .45M 8X 1.25M 20X 2.5

CLEARANCE DIAMETER0.0050.005M 3X .50M 10X 1.5M 24X 3.0 COUNTERBORE DIAMETER0.0100.005M 4X .70M 12X 1.75M 30X 3.5COUNTERBORE DEPTH0.0100.010M 5X .80M 14X 2.0

METRIC COUNTERBORE

D H dD' H' d'11/4/2015Printed copies of Electroimpact standards are for reference only and are not subject to revision control.

REV. E 06/02/2005

SCREWSCREWFLAT HEADFLAT HEADSOCKET C'SINKCLEARANCESCREWSIZEDIA.DIA.HEIGHTSIZEDIA.DIA. d'SIZE

dD (max)H (max)D'CLOSE #20.0860.1970.0640.0500.2143/320.094#2 #40.1120.2550.0831/160.2721/80.125#4 #60.1380.3070.0975/640.324#230.154#6 #80.1640.3590.1123/320.376#150.180#8 #100.1900.4110.1271/80.428#50.206#101/40.2500.5310.1615/320.54817/640.2661/4

3/80.3750.7810.2347/320.79825/640.3913/8

1/20.5000.9380.2515/160.95533/640.5161/2

5/80.6251.1880.3243/81.20541/640.6415/8

3/40.7501.4380.3961/21.45549/640.7663/4

7/80.8751.6880.4689/161.70557/640.8917/8

11.0001.9380.5405/81.9551-1/641.0161

COUNTERSINK DIAMETERS ARE BASED ON THE THEORETICAL MAXIMUM HEAD DIAMETER AT A DEPTH OF .005 TO .015 AND AN ANGLE OF 82 DEGREES. ACTUAL DEPTH MAY VARY DEPENDING ON ACTUAL HEAD DIAMETER AND ANGLECOUNTERSINK DIAMETER TOLERANCES ARE +/- .010

COUNTERSINK ANGLE TOLERANCES ARE +/- 2 DEGREES

FREE SHOULD BE USED UNLESS CLOSE IS REQUIRED

INCH STANDARD COUNTERSINK

82D'd'Dd

HPrinted copies of Electroimpact standards are for reference only and are not subject to revision control.

REV. H 06/02/2005

SCREWSCREWFLAT HEADFLAT HEADSOCKET CLEARANCESCREW

SIZEDIA.DIA.HEIGHTSIZEDIA. d'SIZE

dD (max)H (max) CLOSE inmminmmin mminmminM20.0790.1650.0431.3 mm4.70.1852.20.087M2

M2.50.0980.2070.0541.5 mm5.80.2272.70.106M2.5

M30.1180.2520.0672 mm6.90.2723.50.138M3

M40.1570.3390.0912.5 mm9.40.3694.50.177M4

M50.1970.4170.1103 mm11.60.4575.50.217M5

M60.2360.4960.1304 mm13.90.5466.500.256M6

M80.3150.6610.1735 mm18.30.7218.50.335M8

M100.3940.8270.2176 mm22.80.89710.50.413M10

M120.4720.9840.2568 mm27.01.06412.50.492M12

M140.5511.1020.27610 mm30.41.19714.50.571M14

COUNTERSINK DIAMETERS ARE BASED ON THE THEORETICAL MAXIMUM HEAD DIAMETER AT A DEPTH OF .005 TO .015 AND AN ANGLE OF 90 DEGREES. ACTUAL DEPTH MAY VARY DEPENDING ON ACTUAL HEAD DIAMETER AND ANGLECOUNTERSINK DIAMETER TOLERANCES ARE +/- .010

COUNTERSINK ANGLE TOLERANCES ARE +/- 2 DEGREES

THREAD PITCHES SHOULD ALWAYS BE SPECIFIED,

BUT WHEN METRIC THREADS ARE SPECIFIED WITHOUT A PITCH, THE FOLLOWING PITCHES ARE TO BE USED:M 2X .40M 5X.80M 12X 1.75M 24X 3.0

M 2.5X .45M 6X 1.0M 14X 2.0M 30X 3.5

M 3X .50M 8X 1.25M 16X 2.0

M 4X .70M 10X 1.5M 20X 2.5

16.8 21.025.0

COUNTERSINK

DIAMETER

D' 4.2 5.2 7.0METRIC COUNTERSINK

28.01.1 1.4 1.7 2.3 2.8 3.3 4.4 6.4 8.6 10.6 5.5 6.5 12.6

90D'd'Dd

HPrinted copies of Electroimpact standards are for reference only and are not subject to revision control.

WRENCH FLATS

REV. D 11/1/15

METRIC

SAENOMINALMAX.MIN.WidthMAX.MIN.Width

MMMMMMININININ

44.003.825.0000.1570.1500.197

55.004.785.0000.1970.1880.197

5.55.505.325.0000.2170.2090.197

66.005.785.0000.2360.2280.197

77.006.785.5000.2760.2670.217

2020.0019.6711.4000.7870.7740.449

2121.0020.6711.7000.8270.8140.461

2222.0021.6712.0000.8660.8530.472

2424.0023.6712.7000.9450.9320.500

2727.0026.6713.6001.0631.0500.535

3030.0029.6714.6001.1811.1680.575

Flat should be .866x round size to make flat the same length as on a hex headPrinted copies of Electroimpact standards are for reference only and are not subject to revision control.

Printed copies of Electroimpact standards are for reference only and are not subject to revision control.

BOLT INSTALLATION GUIDELINES

Size10. Torque values for purchased components or specified on Electroimpact assembly drawings supersede the values shown in the table.

Torque (Class 12.9)

Torque (Class 10.9) & Low

HeadTorque (Class 8.8), Flathead,

ButtonHead

Minimum

Engagement

Notes:

1. M5 and under bolts apply purple Loctite 222 or equivalent, except flat heads and button heads anti-seize only.

2. M6 - M10 bolts apply blue Loctite 243 or equivalent, except flat heads and button heads anti-seize only.

3. M12 and over bolts apply copper anti-seize or equivalent.

4. Minimum thread engagement shown should be checked prior to installing bolt. Values shown are for ASTM A36 steel tapped holes with Class

12.9 bolts. If minimum engagement cannot be obtained contact the engineer responsible for the assembly about using a reduced torque value.

5. Loctite or anti-seize should be applied to thread and underside of bolt head or nut.

6. Plated class 12.9 fasteners need to be re-torqued after a minimum of 24hrs from initial torquing to check for hydrogen embrittlement.

7. Closely spaced patterns of bolts attaching a single component, such as slewing rings, should be torqued in an alternating sequence and in steps

up to the final torque.8. Critical bolts that have been fully torqued should not be reused.

9. Values shown are calculated according to VDI2230:2005 using a friction factor of .12 for Loctited bolts and .10 for anti-seize coated bolts to

stress the bolt to 90% of yield.Scott Smith 11/4/2015

Internal Thread Minor Diameter Limits

Rev A 6/24/04

InchMetric

Class 2BClass 6H

ThreadMinMaxThreadMinMaxMin Max

4-400.0940.085M 2 X .401.571.680.0620.066

4-480.0890.097M 2.5 X .452.012.140.0790.084

6-320.1040.114M 3 X .502.462.640.0970.104

8-320.1300.139M 4 X .703.243.470.1280.136

10-240.1450.156M 5 X .804.134.380.1630.173

10-320.1560.164M 6 X 1.04.925.150.1940.203

1/4-200.1960.207M 8 X 1.256.656.910.2620.272

1/4-280.2110.220M 10 X 1.58.388.680.3300.342

5/16-180.2520.265M 12 X 1.7510.1110.440.3980.411

5/16-240.2670.277M 14 X 2.0 11.8412.210.4660.481

quotesdbs_dbs2.pdfusesText_2[PDF] 100 años de lucha libre en mexico pdf

[PDF] 100 common errors in english pdf

[PDF] 100 jours bac algerie

[PDF] 100 pics 2015 quiz answers

[PDF] 100 variante bac

[PDF] 100 variante bac biologie

[PDF] 100 variante bac biologie anatomie si genetica 2009

[PDF] 100 variante bac biologie anatomie si genetica 2015

[PDF] 100 variante bac biologie vegetala si animala

[PDF] 100 variante bac chimie

[PDF] 100 variante bac chimie organica

[PDF] 100 variante bac fizica

[PDF] 100 variante bac geografie

[PDF] 100 variante bac informatica 2009