Curtis Moore

Curtis Moore

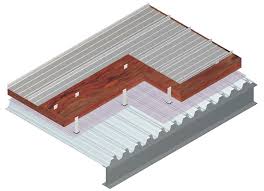

The Kalzip liner-deck roof system has the outer Kalzip standing seam roof sheet and the internal Kalzip liner-deck trapezoidal structural decking sheet laid in

Kalzip Ltd KALZIP STANDING SEAM ROOF SYSTEMS KALZIP

Kalzip Ltd KALZIP STANDING SEAM ROOF SYSTEMS KALZIP

This Certificate relates to the Kalzip Deck Roof System a double skin built-up roof system incorporating standing seam profiled aluminium alloy (coated or

Kalzip® systems Products and applications

Kalzip® systems Products and applications

Kalzip Products. All systems in one view. 6. Kalzip Liner roof system. 12. Kalzip structural deck system. 14. Kalzip Deck roof construction.

Kalzip® Solar Power Systems

Kalzip® Solar Power Systems

Kalzip® standing seam roof sheets are the ideal substrate for PV systems on new buildings and renova- ted roofs as well as when retrofitting. A further alterna

Kalzip® DuoPlus roofing systems Exceptional thermal performance

Kalzip® DuoPlus roofing systems Exceptional thermal performance

The Kalzip DuoPlus E and Duo E roof systems are primarily based on a standard Kalzip standing seam roof build and as such is subject to the same basic set of

Kalzip® Systems made of Aluminium Roof & Facade solutions

Kalzip® Systems made of Aluminium Roof & Facade solutions

Kalzip systems meet the highest require- ments in terms of building physics and design creating roofs and façades with impressive functionality and fascinating.

Kalzip® solar systems Integrated PV roofing solutions for creative

Kalzip® solar systems Integrated PV roofing solutions for creative

Kalzip SolarSysteme. Revolutionary solar modules are providing Kalzip® AluPlusSolar and. Kalzip® SolarClad standing seam systems with both new and retrofit.

Kalzip Walkway systems - Maximum safety due to collective protection!

Kalzip Walkway systems - Maximum safety due to collective protection!

Kalzip roof walkway systems ensure free and safe movement on a slip-resistant surface for all users. Tests of the construction and in particular the

Kalzip® Liner roof systems Form and functionality

Kalzip® Liner roof systems Form and functionality

The Kalzip liner roof system is ideal where speed of installation on a project is of utmost importance. A non-fragile walkable Kalzip liner sheet can be.

Kalzip® systems Products and applications

Kalzip® systems Products and applications

Kalzip Products. All systems in one view. 6. Kalzip Liner roof system. 12. Kalzip structural deck system. 14. Kalzip Deck roof construction.

Kalzip Ltd KALZIP STANDING SEAM ROOF SYSTEMS KALZIP

Kalzip Ltd KALZIP STANDING SEAM ROOF SYSTEMS KALZIP

This Certificate relates to the Kalzip Deck Roof System a double skin built-up roof system incorporating standing seam profiled aluminium alloy (coated or

Kalzip® systems

Kalzip® systems

The Kalzip liner-deck roof system has the outer Kalzip standing seam roof sheet and the internal Kalzip liner-deck trapezoidal structural decking sheet laid in

Kalzip® Systems made of Aluminium Roof & Facade solutions

Kalzip® Systems made of Aluminium Roof & Facade solutions

Kalzip systems meet the highest require- ments in terms of building physics and design creating roofs and façades with impressive functionality and fascinating.

Kalzip® Liner roof systems Form and functionality

Kalzip® Liner roof systems Form and functionality

the event of other failed roofing systems or building enhancements. The Kalzip liner roof system is ideal where speed of installation on a project.

Kalzip® DuoPlus roofing systems Exceptional thermal performance

Kalzip® DuoPlus roofing systems Exceptional thermal performance

Kalzip's DuoPlus E and Duo E roof systems provide a cost effective and seam roofing system this hybrid configuration combines rigid insulation.

Kalzip® solar systems Integrated PV roofing solutions for creative

Kalzip® solar systems Integrated PV roofing solutions for creative

Kalzip® SolarClad standing seam systems with both new and retrofit options. These innovative roof-integrated solar solutions are equipped.

Lightning conduction and protective screening of buildings

Lightning conduction and protective screening of buildings

covers made of Kalzip profile panels as a containment system for the protection ... when using Kalzip roof or wall systems.

Kalzip® FC rainscreen Simple flexible and economical

Kalzip® FC rainscreen Simple flexible and economical

conventional panel systems but also allows scaffolding or subsequent construction work to be coordinated independently from the installation process.

Kalzip® Deck roof systems Statically exactly adjustable and highly

Kalzip® Deck roof systems Statically exactly adjustable and highly

Kalzip Systems. 2. Kalzip GmbH 2020. Kalzip Deck roof system. Kalzip is a flexible weather-resistant

Kalzip® DuoPlus roofing systems Exceptional thermal

Kalzip® DuoPlus roofing systems Exceptional thermal

systems Kalzip’s DuoPlus E and Duo E roof systems provide a cost effective and technically sound solution for roof U-values as low as 0 10 W/m2/K The system was developed in anticipation of the on-going changes to Part L of the Building Regulations and future initiatives with energy efficiency

Kalzip systems - Engineered Architecturals

Kalzip systems - Engineered Architecturals

This system comprises of the Kalzip standing seam outer sheet insulation Kalzip clips VCL and a liner sheet (fig 5) This system is predominantly used for new build construction although it is also suitable for retro-fit especially where the existing roofing system has been completely removed

Kalzip Roof System Guide Specification

Kalzip Roof System Guide Specification

Kalzip™ Guide Specifications This Guide Specification is to be used to develop an office master specification or specifications for a project In either case this Guide Specification must be edited to fit the conditions of use Particular attention should be given to the deletion of inapplicable provisions Include necessary items related to

Searches related to kalzip® systems filetype:pdf

Searches related to kalzip® systems filetype:pdf

Kalzip Maintenance Walkways according to DIN EN 516 (class 1 type C) Kalzip escape routes according to DIN 14094-2 (fire brigade) Width: 500 mm or 800 mmGrilles with anti-slip protection R11 if required with tread strips Includes tilt adjustment to adapt the roof pitch and fixing clamps for penetration-free mounting on Kalzip profiled sheets

What is Kalzip and how does it work?

- Kalzip as a protective screening If the complete building envelope consists of aluminum, i.e. Kalzip systems used for both the roof and wall cladding, the envelope will halt and collect the electrical energy from lightning and safely conduct it to earth thereby preventing dangerous voltages from affecting the power supplies.

What is a Kalzip roof?

- A basic Kalzip system is simply Kalzip sheets directly over open purlins secured with Kalzip clips with (fig. 2) or without (fig. 1) draped foil backed insulation. This type of roof construction can be used on metal building constructions, water reservoir covers or over space framing, such as for arenas, carports or canopies.

What is Kalzip VCL MH?

- Area of application Kalzip VCL MH is used as a vapour control layer for roofs with waterproofing according to DIN 18531, the abc of bituminous sheeting from the vdd e.V. or the flat roof guideline from the ZVDH e.V., preferably on substructures made of trapezoidal steel liner.

Who is Kalzip aluminum standing system?

- Kalzip aluminum standing system is a key brand within the multi-national group. During the past 35 years more than 800 million square feet of Kalzip roofing have been installed around the world – an enviable track record of performance that has firmly established it as the global market leader.

Kalzip® FC rainscreen

Simple, flexible and economical

Kalzip FC Fassadensystem

Inhalt

SeiteKalzip® FC rainscreen -

simple flexible and economicalNew buildings and refurbishment

4Product and system characteristics

5System options and components - General

6Modular click rails

10System accessories

12HYBRID FC Façade -

the innovative facade solutionAesthetics and economy

14Design options in execution

16The system in detail

Kalzip® FC rainscreen system

18Sub-constructions

20Designing with the FC rainscreen system

22Bi-directional panel installation

23Panel removal

24Summary of system benefits

25General information

26Refurbishment

Rostock & Roeger

Omnibus-Zentrum

GmbH, Koblenz (D)

Refurbishment Spiegels

GmbH, Nettetal (D)

Architect:

Engelbert Hanßen

Gewürzmanufaktur Spirit

of Spice, Willich (D)Architect:

Architekturbüro

2Kalzip GmbH 2019

Kalzip FC Fassadensystem

KALZIP® FC RAINSCREEN -

SIMPLE FLEXIBLE AND

ECONOMICAL

Kalzip® FC rainscreen is a non-penetrative

façade system that incorporates a fast-to-install lightweight flat rainscreen panel, suitable for both new build and refurbishment projects.The main feature of the system is its flexibility

which allows the installation of the profiles to be carried out in two directions, either from the top down or from the bottom up.Gries Deco Company GmbH

Niedernberg (D)

Architect: netzwerkarchitekten, Darmstadt

The choice of panel mounting direction is one

of the unique benefits which enables not only easier and faster installation compared to conventional panel systems, but also allows scaffolding or subsequent construction work to be coordinated independently from the installation process. The system"s innovative design and technical capabilities also allow individual panels to be removed and installed without compromising the adjoining panels or the overall integrity of the façade system.3Kalzip GmbH 2018

Kalzip FC Fassadensystem

Based on the versatile application options in

combination with an easy construction design and the outstanding price/performance ratio, the attached and rear ventilated FC facade is the best construction-physical facade const- ruction.It offers the largest possible heat protection;

the aluminum material protects the building reliably and sustainably against weather influ ences and it gives a unique character to the building.FC facade system - simple,

flexible and economicalNew building and refurbishment

The ventilation regulates the moisture balance,

prevents a heat buildup and protects against moisture damages. This simple, sustainable facade concept, developed based on recycling needs, is for many reasons the solution for:New construction

For a new construction, the system is especially

attractive based on its combination variety uni queness of colors and panel width. Different rasters of modular raster click rails for the substructure are available for this purpose.Energetic facade restoration

With respect to the restoration of an existing

building, simple and little plan-related efforts are required to adapt the energy balance of a building to the currently valid and requested energy standard. This dramatically reduces theCO2 emissions and the room climate will be

improved.The simplified design makes it possible to per-

form the adjustment exclusively through the substructure.4Kalzip GmbH 2019

Kalzip FC Fassadensystem

Sophisticated and leading installation

systems n Time-saving installation by latching the sys- tem components in - this is especially cost effective n Freely selectable installation direction from top to bottom or from bottom to top as well as - surface related - independent of adjacent panels. The benefit: The installation is in sync with the construction progress, connections and fit components can be installed retroac- tively - for example, it is possible to delay entire facade fields in the traffic area until the outside systems have been completed. n Easy latching in of the accessories for fixed point, bend part bracket, etc., in the raster click railLogistikzentrum SBF Poing, München

Architects: io-consultants GmbH & Co. KG

n Suitable for the installation on all substructu- res - therefore always the most economic and constructions-physical best solutionExchanging instead of complete dismantling

n Easy and fast exchange of damaged panels using the FC tool kit n Removal of entire facade surfaces with low time and cost expenditures n Guarantee of the optical appearance of the facade at any timeHigh design flexibility for expressive charac-

ter n Level geometric impression with delicate groove raster n Multi-directional installation offers variable design options for architects and planers n Optimized production tolerances based on advanced roll-forming technology.Maximum design flexibility due to a variety

of construction widthsEmphasizing the metallic building enclosure

through expressive colors and surfacesAs a standard, all panels with head bending

at no extra costsFor a sustainable and economic planning

Reduced material use through optimized

panel geometry.If required, cost-saving exchange of indivi-

dual panels - a benefit for the building insu rance.PRODUCT AND SYSTEM

CHARACTERISTICS

The flexible FC rainscreen system made of aluminum with freely selectable installation direction and easy

panel exchangeKalzip GmbH 20185

Kalzip FC Fassadensystem

General information

System options and components

Profile type: FC 30/300FC 30/400FC 30/500FC 30/600FC 30/800Fit panel - const-

ruction width130-299 mm130-

399 mm130-

499 mm130-

599 mm130-

799 mm

Transition sheet

- leg length330 mm430 mm530 mm630 mm830 mmFit panels/transition sheets (max. L= 6,000 mm)

Profile type:FC 30/250FC 30/350FC 30/450FC 30/700

Fit panel - cons

truction width130-249 mm130-349 mm130-449 mm130-749 mmTransition sheet

- leg length280 mm380 mm480 mm730 mmFit panels/transition sheets (max. L= 6,000 mm)

Profile type:Kalzip FC

30/300Kalzip FC

30/400Kalzip FC

30/500Kalzip FC

30/600Kalzip FC

30/800

Profile thick-

ness1,0 mm1,2 mm1,0 mm

1,2 mm-

1,2 mm-

1,47 mm-

1,47 mm

Micro liningnoon requestnonono

Maximal

6.000 mm

panel length for construction > 500 mmStandard construction widths PC panel

Profile type:Kalzip FC

30/250Kalzip FC

30/350Kalzip FC

30/450Kalzip FC

30/700

Profile thick-

ness1,0 mm1,2 mm1,0 mm

1,2 mm-

1,2 mm-

1,47 mm

Micro liningnononono

Maximal

6.000 mm

panel length for construction > 500 mm Intermediate construction widths FC panels (starting at 1000 m2 project size)Transition sheets, upper han

ging (left), lower hanging (right)Profile examples

Kalzip FC Profile and fit

panels without head ben ding Kalzip FC Profile and fit panels with head ben dingSpecial construction widths on request..

6Kalzip GmbH 2019

Kalzip FC Fassadensystem

Head bending

As a standard, FC panels are delivered with head ben ding on both sides at no extra costs. On request, panels can also be produced without head bending.. 17 mm Corner panels can be produced as inner and outer cor- ners with different angles.Corner panel for inner corner

( min. 45°)Corner panel for outer corner ( min. 45°)Corner panels

Specification

Leg 1: min. 150 mm/max. 1,000 mm

Leg 2: min. 300 mm/max. 2,000 mm

Spessart Forum (D), Architect: Planungsbüro Bensing & Partner, Bad Soden-Salmünster 7Kalzip GmbH 2018

Kalzip FC Fassadensystem

Micro-lined panels

Kalzip FC 30/400 with head bending and micro-liningApprox. 20 mm from the upper or lower panel end.

Transition sheets without micro-liningRV 6-8

Share of holes:

min. 44%, max. 48% depending on the panel widthPerforation diameter: 6 mmRV 3-5

Share of holes:

min. 29%, max. 31% depending on the panel widthPerforation diameter: 3 mm

Perforated panels

Deviating perforation on request..

8Kalzip GmbH 2019

Kalzip FC Fassadensystem

Colors and surfaces

nStandard hues

HPC RAL 9006 30% gloss degree, thicknesses: 1.0 - 1.47 mm HPC RAL 9007 30% gloss degree, thicknesses: 1.0 - 1.47 mm HPC RAL 7016 3% gloss degree, thicknesses: 1.0 - 1.47 mm Other RAL, NCS, HPC hues and special hues on request, minimum volume 300 m²Anti-graffiti coating on request

nSurfaces

AluPlusPatina natural aluminum, thicknesses: 1.0 - 1.47 mm AluPlusPatina bronze B40, thicknesses: 1.0 - 1.47 mmAluPlusPatina gold G12, thicknesses: 1,0 - 1.2 mm

minimum volume of additional color patina surfaces 1,000 m² Note: As a standard, all surfaces are delivered with a protective foil.Materials

EN AW-3004, EN-AW-3005 or EN AW-6025

Architect: Stadt Wolfenbüttel,

Amt für Stadtentwicklung, Planen und Bauen

Technical data

Dimensions

nConstruction widths 250 mm - 500 mm

Length: min. 400 mm, max. 8,000 mm

other profile lengths on request nConstruction width > 500 mm - 800 mm

as well as fit panels and transition sheetsLength: min. 400 mm, max. 6,000 mm

Carrying capacity values

Carrying capacity values as per Eurocode 9 and

as per building-authority approval by Deutsches Institut für BautechnikNo. Z-14.1-581

Tolerances

Panel length:

as per Kalzip internal standard L0,4 - 4,00

m +2/-2 mm*L > 4,00 - 8,00

m +3/-3 mm*Rectangularity: as per DIN EN 508-2 a

0,5% of the nominal construction width

Cross arching:

as per EPAQ - European quality directive for profiles: to the outside (+ 0.02* panel width 10 mm) to the inside (- 0.01* panel width < 10 mm) *Temperature note: measured at 20°C 9Kalzip GmbH 2019

Kalzip FC Fassadensystem

Distance caliper

Using the distance caliper, raster click rails,

which must be installed on top of each other, can be adjusted and installed accurately fitting to the construction width of the FC panels wit- hout the need for additional measurements.The tool can be adjusted to the required const-

ruction width with a few hand movements.Raster rail SEThe raster click rail SE is a self-carrying rail,

which can be used as a statically carrying pro- file and therefore it can be fastened at a subst- ructure independent of the latch-in position.Raster rail SEL The raster rail SEL is also a carrying rail and it can be fastened directly at the L wall brackets by using the 50 mm long legs. An additional continuous profile is not required.Penetration-free fastening on modular raster rail

404040

4050

55 mm35 mm

404040

4050System depth with raster

click rail SELSystem depth with raster click rail SE 50 mm70 mm

10Kalzip GmbH 2019

Kalzip FC Fassadensystem

Raster click rails (SE, SEL), standard lengths

3002.985 10350

2.985 9400

2.985 8450

2.985 7500

2.985 6600

2.985 5800

2.985 4250

2.985

12Standard length short in mm

Number of hanging points

5.935205.935

175.935

155.750

135.935

125.935

105.935

85.935

24Standard long short in mm

Number of hanging points

Fitness Center, Portland (UK)

Type11Kalzip GmbH 2019

Kalzip FC Fassadensystem

Fixed-point clamp

To guarantee a uniform vertical joint pattern, each panel must be fixated in its defined position by a system-related fixed-point clamp. The fixed- point clamp can be re-released and fixated again after the installation and alignment of the panel, using an Allen wrench, if required, even through the horizontal panel joint.Guidance snapper The guidance snappers ensure a steady gap between the panels and therefore guarantee an even joint pattern. The use of guidance snappers is mandatory for very short panels and corner panels as well as for verti cal overhead installations. Information can be found in the installation guideline. Sophisticated system accessories for a perfect result12Kalzip GmbH 2019

Kalzip FC Fassadensystem

Bend part bracket

A bend part bracket pluggable on the raster rails is available for an easy and quick fastening of bend parts (lisene, corner, soffit and connection profiles). The brackets latch into the provided perforation and offer - without additional adjustment - a level surface for the reception of the bend parts.Adapter for SE and SEL rail The FC adapter permits a simple installation of FC fit panel widths from130 mm up to the used panel construction width (see page 6) in the

pedestal and attic area as well as above and below of openings within the facade surface (e.g. doors and windows). The FC adapter is delivered with 2 complete plastic inlays and therefore, it can be used for the upper as well as the lower connection. Number and arrangement for the fastening of lesene: approx. 1.5 units/m (arranged offset)FC adapter for SEL rail

Length 94 mm, depth 33 mm

without inlay, 3 holes, hole diameter: 5.2 mmFC adapter for SE railLength 94 mm, depth 53 mm

without inlay, 3 holes, hole diameter: 5.2 mmRestoration Rostock & Roeger

Omnibus-Zentrum GmbH, Koblenz (D)

13Kalzip GmbH 2019

Kalzip FC Fassadensystem

HYBRID FC facade -

the innovative facade solutionDesign and economic feasibility

The combination of energy efficiency, econo-

mic feasibility and highest design versatility makes the HYBRID FC facade the most innova tive facade solution for industry and business construction. It was developed as a joint pro- duct of the two companies Fischer Profil undKalzip®. It combines the strengths of both

brands - the economic design and the high aesthetic claims.The HYBRID FC facade, which is approved by

the construction authorities, consists of a clam- shell wall cover: The FischerTherm steel sand wich element is connected to the attached, rear ventilated FC aluminum facade by Kalzip®.The FC panels on the sandwich element is ins

talled by using the SE raster click rails and a newly developed fastening material. The rail is in this case only fastened at the outer shell - it does not penetrate the sandwich ele- ment. A substructure is therefore not required Fast economic installation of the FischerTHERM sandwich elements with DUO sealing. Direction-depending installation of the Kalzip FC panels.. 14Kalzip GmbH 2019

Kalzip FC Fassadensystem

Discover

the benefits at a glance!quotesdbs_dbs9.pdfusesText_15[PDF] Kamil Sza?ata

[PDF] Kaminholz aus dem Sauerland - Kaminholz

[PDF] Kamishibaï les trois cochons

[PDF] Kamo et moi - Cercle Gallimard de l`enseignement

[PDF] Kamo, l`agence Babel

[PDF] KAMPA AG erwirbt Hebel Haus

[PDF] Kampfkunst und Recht Kampfkunst und Recht

[PDF] Kampfschwimmer-Uhr von Rolex Panerai: Werk: Rolex Cal. 5513

[PDF] Kanada - DHBW Stuttgart

[PDF] Kanalrauchmelder KRM - Oppermann Regelgeräte GmbH

[PDF] KANBAN - Gestion De Projet

[PDF] KANBAN ET LE DÉVELOPPEMENT LOGICIEL AGILE - Gestion De Projet

[PDF] Kanban, mettre en œuvre la méthode dans l`IT - De LAutomobile Et Des Véhicules