Metric Tap & Tap Drill Clearance Drill Clearance Drill Sizes

Metric Tap & Tap Drill Clearance Drill Clearance Drill Sizes

LittleMachineShop com • (800) 981-9663 Tap & Clearance Drill Sizes Tap Drill Clearance Drill Screw Size Major Diameter Plastics Threads Per Inch Minor Aluminum, Brass, Diameter 75 Thread for & 50 Thread for Steel, Stainless, & Iron Close Fit Free Fit Drill Size Dec Eq Drill Size Dec Eq Drill Size Dec Eq Drill Size Dec Eq

Using the Three-Wire Method to Measure Threads

Using the Three-Wire Method to Measure Threads

©2011 LittleMachineShop com Page 3 of 4 Chris’ Tip: You can find the pitch diameter of unified and metric screw threads in Machinery’s Handbook and also in Machineries Handbook Pocket Companion Both of these books are available from LittleMachineShop com Wire Sizes and Constants TPI Wire Size Const TPI Wire Size Const

Metric Tap & Clearance Drill Sizes - University of Washington

Metric Tap & Clearance Drill Sizes - University of Washington

LittleMachineShop com • (800) 981-9663 Tap & Clearance Drill Sizes Tap Drill Clearance Drill 75 Thread for Aluminum, Brass, & Plastics 50 Thread for Steel, Stainless, & Iron Screw Close Fit Free Fit Size Major Diameter Threads Per Inch Minor Drill Size Dec Eq Drill Size Dec Eq Drill Size Dec Eq Drill Size Dec Eq

Metric Acme Thread Dimensions Chart

Metric Acme Thread Dimensions Chart

Metric Screw Thread Chart The design principles of ISO general-purpose metric screw threads ("M" series threads) are defined in international standard ISO 68-1 Each thread is characterized by its major diameter, D (D maj in the diagram), and its pitch, P ISO metric threads consist of a symmetric V-shaped thread

DECIMAL EQUIVALENTS CHART - Fastenal

DECIMAL EQUIVALENTS CHART - Fastenal

MACHINE SCREW, FRACTIONAL & METRIC SIZES Inch Metric Cutting Taps Forming Taps Tap Size & Pitch Drill Size Dec Equiv Drill Size Dec Equiv 0-80 3/64 0469 54 0550

TAP DRILL SIZES - INCH & METRIC with DRILL SIZE FORMULAS

TAP DRILL SIZES - INCH & METRIC with DRILL SIZE FORMULAS

FORMULA FOR TAP/DRILL SIZES (METRIC) Figures in table show amount to subtract from O D of screw to obtain specific percentages of thread Select nearest size commercial stock drill METHOD 1: Drilled Hole Size (mm) = Basic Major Dia Of Thread (mm) - *Use whole numbers for of thread for 65 , use 65 (not 65) METHOD 2:

Counterbore Hole Dimensions For Metric Socket Head Cap Screws

Counterbore Hole Dimensions For Metric Socket Head Cap Screws

LittleMachineShop com • (800) 981-9663 Tap & Clearance Drill Sizes Tap Drill Clearance Drill Screw Size Major Diameter Plastics Threads Per Inch Minor Aluminum, Brass, Diameter 75 Thread for & 50 Thread for Steel, Stainless, & Iron Close Fit Free Fit Drill Size Dec Eq Socket Head Cap Screw Size Chart

Inch/MetrIc tap DrIll SIzeS & DecIMal equIvalentS

Inch/MetrIc tap DrIll SIzeS & DecIMal equIvalentS

Drill Size Decimal eQUiValent tap Size 80 0135 1 79 0145 64 0156 78 0160 77 0180 metric tap Drill SizeS metric tap tap Drill (mm) Decimal (inch) m1 6 x 0 35

[PDF] MEDIA-NAV Evolution - Renault Multimedia

[PDF] la profession de masseur- kinésithérapeute - Tel archives ouvertes

[PDF] La VAE en Midi-Pyrénées dans les secteurs social, paramédical

[PDF] Candidats DRJSCS - IRTS Montpellier

[PDF] des masseurs-kinésithérapeutes - Le conseil interrégional de PACA

[PDF] manuels scolaires 2014-2015 premiere stmg - Ensemble Scolaire

[PDF] Maroc - Loi n°1999-65 relative au Code du Travail - Droit-Afrique

[PDF] Le droit administratif

[PDF] Le droit administratif

[PDF] introduction generale au droit administratif - Redouan Larhzal

[PDF] DROIT ADMINISTRATIF

[PDF] Doctrine et droit administratif - Mohammed Amine BENABDALLAH

[PDF] Revue - Fondation Droit Animal

[PDF] LE DROIT AU JUgE ET ? UN RECOURS EffECTIf SELON LA

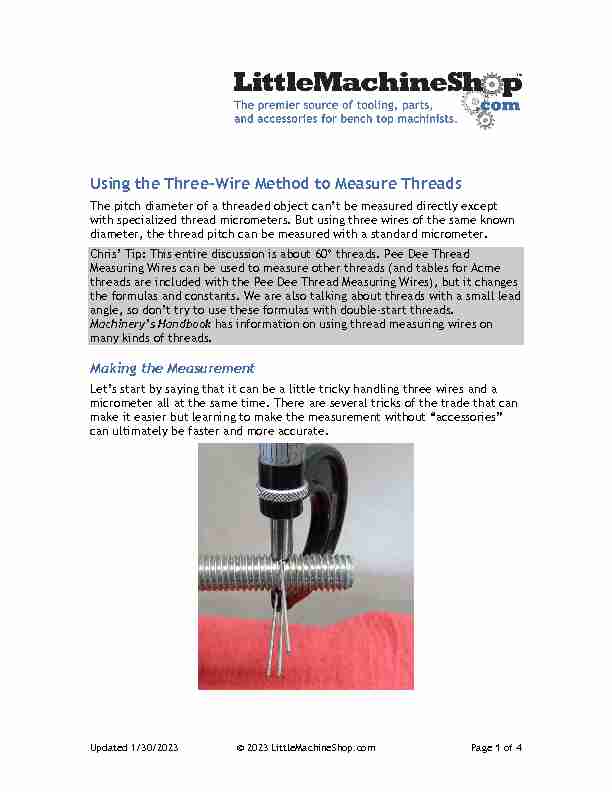

Updated 1/30/2023 © 2023 LittleMachineShop.com Page 1 of 4 Using the Three-Wire Method to Measure Threads The pitch diameter of a threaded object can't be measured directly except with specialized thread micrometers. But using three wires of the same known diameter, the thread pitch can be measured with a standard micrometer. Chris' Tip: This entire discussion is about 60° threads. Pee Dee Thread Measuring Wires can be used to measure other threads (and tables for Acme threads are included with the Pee Dee Thread Measuring Wires), but it changes the formulas and constants. We are also talking about threads with a small lead angle, so don't try to use these formulas with double-start threads. Machinery's Handbook has information on using thread measuring wires on many kinds of threads.

Updated 1/30/2023 © 2023 LittleMachineShop.com Page 1 of 4 Using the Three-Wire Method to Measure Threads The pitch diameter of a threaded object can't be measured directly except with specialized thread micrometers. But using three wires of the same known diameter, the thread pitch can be measured with a standard micrometer. Chris' Tip: This entire discussion is about 60° threads. Pee Dee Thread Measuring Wires can be used to measure other threads (and tables for Acme threads are included with the Pee Dee Thread Measuring Wires), but it changes the formulas and constants. We are also talking about threads with a small lead angle, so don't try to use these formulas with double-start threads. Machinery's Handbook has information on using thread measuring wires on many kinds of threads.