bar psi kPa/MPa Kg/cm2 Mbar

Page 1. bar psi. kPa/MPa. Kg/cm2. Mbar. 0.025. 0.363. 2.5 kPa. 0.025. 25. 0.04. 0.58 5. 72.516. 500 kPa. 5.098. 5000. 6. 87.020. 600 kPa. 6.117. 6000.

pdf pressure card

TABLE A-2 Properties of Saturated Water (Liquid–Vapor

Source: Tables A-2 through A-5 are extracted from J. H. Keenan F. G. Keyes

Tableswater

TABLE A-5 Properties of Compressed Liquid Water T v 103 u h s v

Page 1. 728 Tables in SI Units. H. 2O. TABLE A-5 Properties of Compressed Liquid Water 15.0 bar 1.5 MPa. (Tsat. 179.91C). (Tsat. 198.32C). Sat. 0.1944.

steam tables

Solenoid/pneumatic valves Tiger Classic

1. 10. 11. 12. 13. 7. 4. 9. 8. 1. 3. 5. 2. 4. 6. 1. Variants. MFH-5-. 1.5 ... 8. 2 ... 8. External pilot air supply. [MPa]. –0.095 ... 1. [bar].

Chap 5 Solns

7.8 A sheet of BCC iron 1 mm thick was exposed to a carburizing gas atmosphere on one side and a diffusion flux is 1.5 × 10-8 kg/m2∙s.

chapter sol

Thermodynamic Properties and calculation

Air at 1 bar and 298.15K (25℃) is compressed to 5 bar and 298.15K by two different mechanically reversible processes: ○ (a) Cooling at constant pressure

Thermodynamic Properties

Pressure regulators LR/LRS/LRB/LRBS D series

https://www.festo.com/media/pim/123/D15000100122123.PDF

Parker Hydraulic Hoses Fittings and Equipment Catalogue

%20Fittings%20and%20Equipment%20Catalogue%20CAT_4400_UK.pdf

CONSTRUCTION MATERIAL MS 146: 2014

1. BS 4449:1997. * Note: Bar marking at 1.5m with no std. This standard contains provisions for three steel grades all of 500 MPa.

ms cidb final haji sabrudin

AUTOMA TIC CONTROLS

*1・ Standard unit display is MPa. Other unit displays are available upon request by changing “X0” portion of a catalog number. [X0: MPa X1: bar

catalog en

Excerpts from this work may be reproduced by instructors for distribution on a not-for-profit basis for testing or instructional

purposes only to students enrolled in courses for which the textbook has been adopted. Any other reproduction or translation of

this work beyond that permitted by Sections 107 or 108 of the 1976 United States Copyright Act without the permission of the

copyright owner is unlawful.CHAPTER 7

DIFFUSION

PROBLEM SOLUTIONS

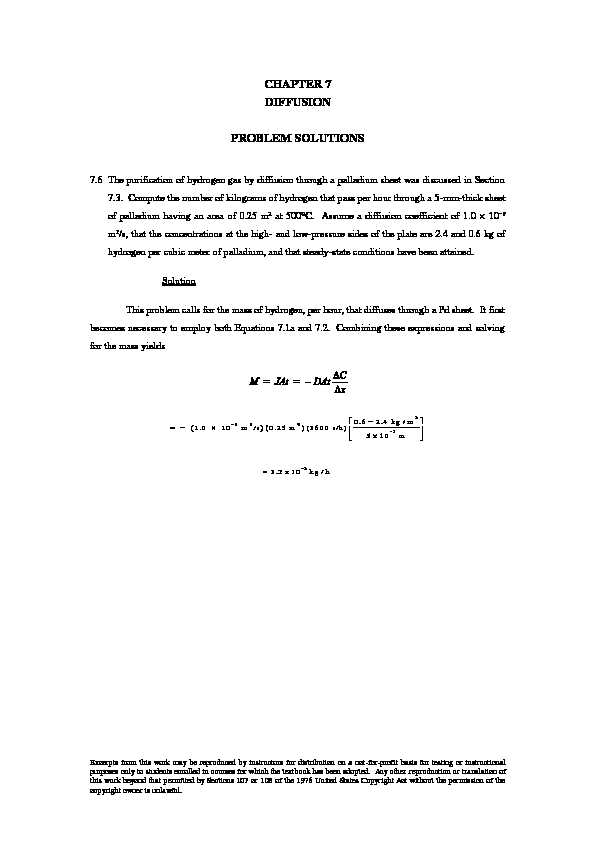

7.6 The purification of hydrogen gas by diffusion through a palladium sheet was discussed in Section

7.3. Compute the number of kilograms of hydrogen that pass per hour through a 5-mm-thick sheet

of palladium having an area of 0.25 m2 at 500C. Assume a diffusion coefficient of 1.0 108 m2/s, that the concentrations at the high- and low-pressure sides of the plate are 2.4 and 0.6 kg of hydrogen per cubic meter of palladium, and that steady-state conditions have been attained.Solution

This problem calls for the mass of hydrogen, per hour, that diffuses through a Pd sheet. It first becomes necessary to employ both Equations 7.1a and 7.2. Combining these expressions and solving for the mass yields 3 8 2 2 30 .6 2 .4 k g / m= 1 .0 1 0 m /s 0 .2 5 m (3 6 0 0 s/h )

5 1 0 m( ) ( )

uExcerpts from this work may be reproduced by instructors for distribution on a not-for-profit basis for testing or instructional

purposes only to students enrolled in courses for which the textbook has been adopted. Any other reproduction or translation of

this work beyond that permitted by Sections 107 or 108 of the 1976 United States Copyright Act without the permission of the

copyright owner is unlawful.