3D printers print objects from computer models to real 3D physical objects. The printing is done layer by layer using different materials. As different

Study I presents a legal and an empirical analysis of 3D printing a case study approach; the Executive Summary provides a summary of the findings of ...

Study

rail maintenance center with FDM® 3D printing at the heart of its servicing operation. Pulling Its. Weight. Siemens Mobility Boosts Custom Production.

cs fdm au siemensmobility a a

3D Printing. Kärcher is a name familiar to many households and gardeners and its distinctive yellow and black logo is synonymous with cleaning systems

cs du cm kaercher a a web ?v= fda

As part of this study we have developed wood-based bio-composite materials that are 3D printed with wood filament. Shape-changing behavior is not predictable

caadria

MEDICAL. CASE STUDY. 3D PRINTED RIB. IMPLANTED IN THE HUMAN BODY. Physicians decided on 3D printing technolo- gy because it guarantees perfect reproduc-.

Case Study D printed rib en

Stratasys

La qualité est l'un des piliers de la réussite d'Elkamet. Kunststofftechnik GmbH fabricant allemand de pièces en plastique présent sur le marché.

through these technologies the Innovation Project team launched a case study on 3D bio- printing. Health Canada led these discussions with the following

ICMRA Innovation WS D Bio printing

A Hybrid Method to Trace Technology Evolution Pathways: A Case. Study of 3D Printing. Ying Huang1 Donghua Zhu1

A Hybrid Method to Tracing Technology Evolution Pathways A Case Study of D Printing

A Case Study of 3D Printing Materials used for the case study due to the growing use of 3D printing technology. The information ... _2017.pdf.

qt mk x f noSplash cad cacf d bf f dd c

214806

MEDICAL

CASE STUDY

3D PRINTED RIB

IMPLANTED IN THE HUMAN BODY

Physicians decided on 3D printing technolo

gy because it guarantees perfect reproduc tion of the shape of the original rib in terms of its thickness and bending.

In this case, the absolute dimensional

accuracy of the implant was required. The use of a 3D printer as a tool allowed the reconstruction of the rib. The basis for implant placement was that the wall structures to ensure proper restoration.

Before the operation, 3 mm holes were

drilled in the 3D printing to facilitate regene ration and rapid renewal of the connective tissue.The rib implant made with the use of 3D printing technology was properly sterilized in ethylene oxide.

The 3D printout was also subjected to steriliza

tion using gamma radiation and steam at

140 ° C.Why 3D printing?Implantation of a 3D print

in the human bodyRib sterilization process

Rib implant

3D print

Description

Material

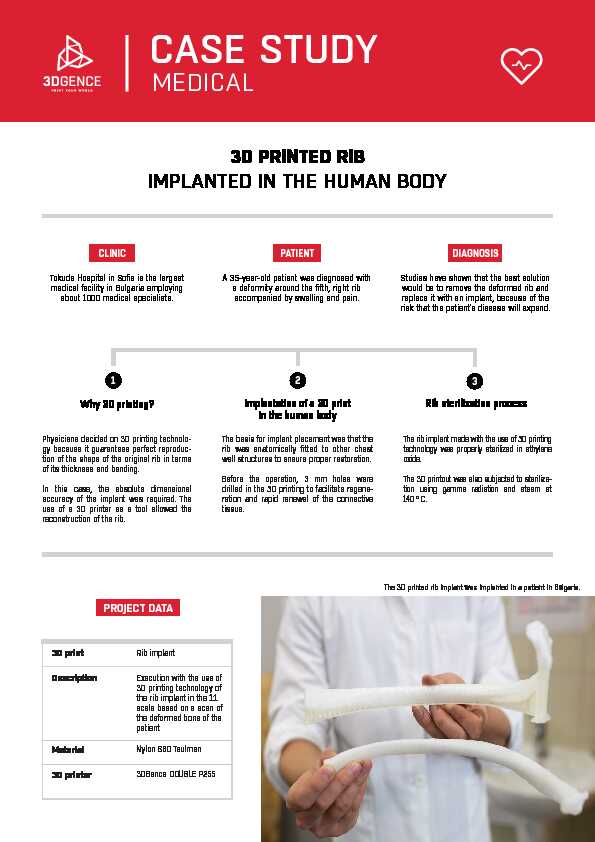

3D printer The 3D printed rib implant was implanted in a patient in Bulgaria.

1 medical facility in Bulgaria employing about 1000 medical specialists.

CLINIC

Studies have shown that the best solution

would be to remove the deformed rib and replace it with an implant, because of the risk that the patient's disease will expand.

DIAGNOSIS

A 35-year-old patient was diagnosed with

accompanied by swelling and pain.

PATIENT

Work on the rib implant began with the initial 3D

visualization, the bone was scanned in the hospital, and then the scan was passed to a team of experts who developed a digital rib model and prepared it for printing in 3D technology.

The individually designed rib implant is made of

The process of sterilization of a printed rib implant. X-ray image of a patient's bone suffering from cystic dystrophy of the rib. An individually designed rib model and its faithful reproduction in printing allowed for the implantation of a new element in place of the removed bone. Replacing the missing rib with a 3D printed segment of the same shape, curve, width, and thickness was possible using a 3DGence 3D printer.

Prof. Minchev

3DGence

3DGence is a Polish manufacturer of

3D printers specializing in the

development of new technological solutions and the implementation of 3D printing in industrial enterprises.3DGence Sp. z o.o. ul. Graniczna 66

44-178 Przyszowice

Sales department: +48 32 438 98 91

Support: +48 32 438 98 64

E-mail: cs@3dgence.com

Services: 3dservices@3dgence.com

MEDICAL

CASE STUDY

3D PRINTED RIB

IMPLANTED IN THE HUMAN BODY

Physicians decided on 3D printing technolo

gy because it guarantees perfect reproduc tion of the shape of the original rib in terms of its thickness and bending.

In this case, the absolute dimensional

accuracy of the implant was required. The use of a 3D printer as a tool allowed the reconstruction of the rib. The basis for implant placement was that the wall structures to ensure proper restoration.

Before the operation, 3 mm holes were

drilled in the 3D printing to facilitate regene ration and rapid renewal of the connective tissue.The rib implant made with the use of 3D printing technology was properly sterilized in ethylene oxide.

The 3D printout was also subjected to steriliza

tion using gamma radiation and steam at

140 ° C.Why 3D printing?Implantation of a 3D print

in the human bodyRib sterilization process

Rib implant

3D print

Description

Material

3D printer The 3D printed rib implant was implanted in a patient in Bulgaria.

1 medical facility in Bulgaria employing about 1000 medical specialists.

CLINIC

Studies have shown that the best solution

would be to remove the deformed rib and replace it with an implant, because of the risk that the patient's disease will expand.

DIAGNOSIS

A 35-year-old patient was diagnosed with

accompanied by swelling and pain.

PATIENT

Work on the rib implant began with the initial 3D

visualization, the bone was scanned in the hospital, and then the scan was passed to a team of experts who developed a digital rib model and prepared it for printing in 3D technology.

The individually designed rib implant is made of

The process of sterilization of a printed rib implant. X-ray image of a patient's bone suffering from cystic dystrophy of the rib. An individually designed rib model and its faithful reproduction in printing allowed for the implantation of a new element in place of the removed bone. Replacing the missing rib with a 3D printed segment of the same shape, curve, width, and thickness was possible using a 3DGence 3D printer.

Prof. Minchev

3DGence

3DGence is a Polish manufacturer of

3D printers specializing in the

development of new technological solutions and the implementation of 3D printing in industrial enterprises.3DGence Sp. z o.o. ul. Graniczna 66

44-178 Przyszowice

Sales department: +48 32 438 98 91

Support: +48 32 438 98 64

E-mail: cs@3dgence.com

Services: 3dservices@3dgence.com