f-35b - the worlds first supersonic stovl aircraft

f-35b - the worlds first supersonic stovl aircraft

For the first time in aviation history supersonic

dod Programs - F-35 Joint Strike Fighter (JSF)

dod Programs - F-35 Joint Strike Fighter (JSF)

- F-35A Conventional Take-Off and Landing (CTOL). - F-35B Short Take-Off and Vertical Landing (STOVL). - F-35C Aircraft Carrier Variant (CV). • It is designed

Preparation of Papers for AIAA Journals

Preparation of Papers for AIAA Journals

29 jun 2018 into the engine inlet and exhaust nozzle and the F-35B short takeoff and vertical landing (STOVL) propulsion system

F-35 STOVL Performance Requirements Verification

F-35 STOVL Performance Requirements Verification

The F-35B is the short takeoff and vertical landing (STOVL) variant of the F-35 with two challenging and unique requirements. First

DOD PROGRAMS - F-35 Joint Strike Fighter (JSF)

DOD PROGRAMS - F-35 Joint Strike Fighter (JSF)

16 nov 2012 - F-35A Conventional Take-Off and Landing (CTOL). - F-35B Short Take-Off/Vertical-Landing (STOVL). - F-35C Aircraft Carrier Variant (CV). • It ...

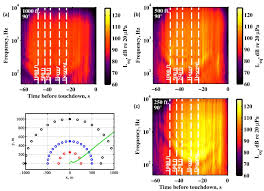

Acoustical Environment of an F-35B Aircraft During Vertical Landings

Acoustical Environment of an F-35B Aircraft During Vertical Landings

1-5. However the short take-off and vertical landing (STOVL) capability of the F-35B represents a more complicated environment than for traditional aircraft

Marine Corps F-35Bs Conduct First Landing Aboard JS Izumo

Marine Corps F-35Bs Conduct First Landing Aboard JS Izumo

3 oct 2021 short takeoff and vertical landing (STOVL) operations a capability that the “B” variant of the F-35 specializes in

dod Programs - F-35 Joint Strike Fighter (JSF)

dod Programs - F-35 Joint Strike Fighter (JSF)

- F-35A Conventional Take-Off and Landing (CTOL). - F-35B Short Take-Off/Vertical-Landing (STOVL). - F-35C Aircraft Carrier Variant (CV). • It is designed to

Distributed STOVL Operations and Air-Mobility Support: Addressing

Distributed STOVL Operations and Air-Mobility Support: Addressing

–vertical-landing (STOVL) operations (DSOs) by U.S. Marine Corps. F-35B Lightning II Each F-35 would load missiles and six tons of fuel after each sortie ...

F-35 Lightning II

F-35 Lightning II

F-35B STOVL. Performance. Top Speed: 1.6 Mach (1200mph). Combat radius: >450nm F-35B Vertical Landing (VL). The advanced control system and flight deck ...

F-35B Integrated Flight-Propulsion Control Development

F-35B Integrated Flight-Propulsion Control Development

The Short Take-Off Vertical Landing (STOVL) variant of the F-35 Joint Strike Fighter. (JSF) is a multirole air-ground and air-air fighter that offers the

UNCLASSIFIED F-35 Lightning II Joint Strike Fighter (JSF) Program

UNCLASSIFIED F-35 Lightning II Joint Strike Fighter (JSF) Program

30 déc. 2019 The F-35B variant will be a multi-role strike fighter aircraft to replace the AV-8B and ... STOVL - Short Takeoff and Vertical Landing.

f-35b - the worlds first supersonic stovl aircraft

f-35b - the worlds first supersonic stovl aircraft

For the first time in aviation history supersonic

dod Programs - F-35 Joint Strike Fighter (JSF)

dod Programs - F-35 Joint Strike Fighter (JSF)

F-35B Short Take-Off/Vertical-Landing (STOVL). - F-35C Aircraft Carrier Variant (CV). • It is designed to survive in an advanced threat (year 2012 and.

Backgrounder - GKN Aerospace on the Lockheed Martin F-35

Backgrounder - GKN Aerospace on the Lockheed Martin F-35

landing (CTOL) the F-35B short take-off and vertical landing (STOVL) and the F-35C carrier variant. (CV) aircraft. Cockpit Transparency. The F-35

F-35_Air_Vehicle_Technology_Overview.pdf

F-35_Air_Vehicle_Technology_Overview.pdf

29 juin 2018 The Lockheed Martin F-35 Lightning II incorporates many ... and the F-35B short takeoff and vertical landing (STOVL) propulsion system.

Distributed STOVL Operations and Air-Mobility Support: Addressing

Distributed STOVL Operations and Air-Mobility Support: Addressing

takeoff–vertical-landing (STOVL) operations (DSOs) by U.S. Marine Corps. F-35B Lightning II fighters and alternative solutions to fulfilling those require-.

BUQUE DE PROYECCIÓN ESTRATÉGICA (BPE)

BUQUE DE PROYECCIÓN ESTRATÉGICA (BPE)

Landing) des années 80. engins de débarquement à coussin d'air LCAC (Landing ... Utiliser le chasseur multi-rôles STOVL F-35B semblerait logique.

Marine Corps F-35Bs Conduct First Landing Aboard JS Izumo

Marine Corps F-35Bs Conduct First Landing Aboard JS Izumo

3 oct. 2021 landing of two F-35B Lightning II aircraft aboard the Japanese ... short takeoff and vertical landing (STOVL) operations a.

Backgrounder

September 2018

GKN Aerospace on the Lockheed Martin F-35 Lightning II Global involvement by GKN Aerospace facilities includes: The design and supply of the aircraft͛s sophisticated canopy The manufacture of high value composite assemblies and precision-machined aluminium and titanium metal structures. The design and Centre of Excellence for the supply of the complex High end composite Inflight opening doors and Flaperons & CV Outboard Leading flaps for all variants Design improvements, industrialization, tooling design and manufacturing of the drag chute fairing assembly. The design and supply of the highly advanced Arresting gear system for all variants, the arresting gear for the F-35C was successfully re-designed The development of breakthrough composite technology for composite drag brace and composite landing gear components, The design and supply of the complete Electrical Wiring Interconnection System(EWIS) for all variants The design and supply of the advanced all-composite engine front fan case The supply of the electro-thermal ice protection system for the F135 engine - and embedding the heater mats into the engine front fan case For the F135 engine, the supply of complex titanium metal structures. For the F135 engine a part of the electrical wiring system These work packages encompass the three F-35 variants: the F-35A conventional take-off and landing (CTOL), the F-35B short take-off and vertical landing (STOVL) and the F-35C carrier variant (CV) aircraft.Cockpit Transparency

The F-35 transparency comprises a framed windshield and canopy made from stretched acrylic. Thecanopy is produced from a single piece of acrylic with no steps or gaps in the outside mould line and

has speciality coatings applied to maintain low-observable characteristics. GKN Aerospace provides each transparency to Lockheed Martin coated, trimmed and drilled, with bushings and seals ready for installation to the frame. Frame construction, assembly and installation are undertaken byLockheed Martin.

Electro Thermal De-icing

GKN Aerospace supplies Pratt & Whitney with the electro-thermal heater mats for the advanced Engine Ice Protection System (EIPS) on the F135 engine. The heater mats are manufactured at the GKN Aerospace facility in Luton, England. The company is responsible for the integration of the mats into the forward fan case for the F135 engine, which GKN Aerospace also supplies. This system removes the need to bleed hot air from the engine, increasing fuel efficiency and the performance and endurance of the F135 engine.Composite and Metal Components and Structures

GKN Aerospace at Filton and Cowes in the UK and El Cajon, Premac, Monitor, Tallassee and St. Louis in the USA are responsible for the manufacture of a large number of complex aluminium, titanium and composite structures for both the airframe and engine of the F-35 Lightning II. This includes bulkheads, composite panels, primary and secondary structures and much of the outer engine casing for the F-135 engine. Complex High-end composite Inflight Opening Doors and Flaperons & CV Outboard Leading flaps GKN Fokker through its facility in Hoogeveen the Netherlands is responsible for the manufacture of a large number of complex integrated composite structures for the airframe of the F-35 Lightning II.The hybrid structures holds many of GKN Fokker͛s key technologies. The structures included but not

limited are Nose & Main Landing Gear Doors, Lift Fan Doors, Refuelling Doors and other system doors together with the Flaperons for all variants.Drag Chute Fairing Assembly

A composite /metal construction that enables the F-35 Lightning II to release the drag chute. Drag chutes are used for fighter aircraft that operate from shorter runways or from wet or icy runways in cold climates. Norway has been the first country to receive the drag chute system, and Canada and the Netherlands are considering adding this capability to some of their F-35 aircraft. Under this agreement, GKN Fokker in Hoogeveen is responsible for the drag chute fairing which is a complex component that protects the chute and mechanisms during flight and opens to release the chute at landing.Electrical Wiring Interconnection system (EWIS)

GKN Fokker Elmo is responsible for the engineering, manufacturing and production of the complete Electrical Wiring & Interconnection Systems (EWIS) on all F-35 Lightning II Joint Strike Fighter versions. GKN Fokker͛s proprietary wiring design and manufacturing system (WDMS) integrates all aspects of wiring management into one powerful online system with a unique configuration and change control. On the 1st power-on of the F-35 (in 2005) the GKN Fokker EWIS demonstrated results of 100% function and fit which never happened before. EWIS production takes place in Hoogerheide, the Netherlands (majority of the work) and in Izmir Turkey .Arresting Hook system on F-35C

GKN Fokker Landing Gear Business in Helmond has designed, developed and produced the F-35C͛s arresting hook system, which was redesigned with additional stiffness and revised shaping.Composite Drag brace

UTAS and GKN Fokker Landing Gear in Helmond work together to produce PMC (composite) drag braces to be incorporated into the main landing gear for F-35 conventional take-off/landing (CTOL) and short take-off/vertical landing (STOVL) variants. GKN Fokker͛s role encompasses detailed component design, qualification and production. Compared to the metallic brace equivalent, using PMC materials result in reduced weight, shorter production lead-time and lower maintenance costs over the life of the F-35. In March 2015 together with the Dutch National Aerospace Centre (NLR) a pilot plant for the production of composite landing Gear components was opened in Marknesse, the Netherlands. GKN Fokker Landing Gear is now ramping up for serial production.quotesdbs_dbs2.pdfusesText_2[PDF] f 35 stovl performance requirements verification

[PDF] f 35 stovl takeoff

[PDF] f 35 stovl takeoff distance

[PDF] f 35 supercruise

[PDF] f 35 timeline

[PDF] f 35 work breakdown structure

[PDF] f a cotton group theory pdf

[PDF] f p santangelo

[PDF] f sd scg 4000

[PDF] f sharp tutorial pdf

[PDF] f35 capabilities

[PDF] f35 failure

[PDF] f35 for sale

[PDF] f35 sensors