FANUC Robot series R-30iB Mate + Mate Plus Maintenance Manual

FANUC Robot series R-30iB Mate + Mate Plus Maintenance Manual

SRVO-295 Amp com error. SRVO-297 Improper input power. SRVO-335 DCS OFFCHK alarm a b. SRVO-348 DCS MCC OFF alarm a

FANUC Robot series

FANUC Robot series

SRVO-266 through SRVO-275 and SRVO-370 through SRVO-385 are issued at the same (89) SRVO-348 DCS MCC OFF alarm a b. (Explanation) A command was issued to ...

OPERATORS MANUAL(Collaborative Robot Function)

OPERATORS MANUAL(Collaborative Robot Function)

SYST-348 Payload Monitor (Force) warning. • SYST-349 Payload Monitor (Moment) “SRVO-473 DCS CLLB CC_EXTF alarm” occurs. Verify followings. • Refer to A.2 ...

FANUC Robot series R-30iB/R-30iB Mate/R-30iB Plus/R-30iB Mate

FANUC Robot series R-30iB/R-30iB Mate/R-30iB Plus/R-30iB Mate

SRVO-339 DCS MISC alarm i j. SRVO-344 DCS GRP alarm(G i) j

HG-KN/HG-SN SERVO MOTOR INSTRUCTION MANUAL

HG-KN/HG-SN SERVO MOTOR INSTRUCTION MANUAL

Do not attempt to wire the servo amplifier and servo motor until they have been installed. 348 Victoria Road P.O. Box 11

1394-5.0-MAY00 1394 Digital AC Multi-Axis Motion Control System

1394-5.0-MAY00 1394 Digital AC Multi-Axis Motion Control System

servo drive system or an analog servo drive system. All 1394 systems [Jog Vel] parameter (348

mr-j4-_b_-ll servo amplifier instruction manual

mr-j4-_b_-ll servo amplifier instruction manual

POINT. When you connect the servo amplifier to a servo system controller servo 348 Victoria Road

OMNUC G5 SERIES AC SERVOMOTORS/SERVO DRIVES USERS

OMNUC G5 SERIES AC SERVOMOTORS/SERVO DRIVES USERS

SERVO DRIVE USER'S MANUAL. 3. Specifications. Model (R88M-). Item. Unit. 400 VAC ... 348. 5-11. 5-2 Speed Control. OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE ...

FANUC Series 0i-MODEL C/0i Mate-MODEL C MAINTENANCE

FANUC Series 0i-MODEL C/0i Mate-MODEL C MAINTENANCE

348 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.4.5.1 Starting the built–in ...

SureServo2™ AC Servo Systems User Manual

SureServo2™ AC Servo Systems User Manual

348. Chapter 7: Motion Control. Page 7–137. SureServo2 User Manual – 2nd Edition – 08/10/2023. Parameters. DI/DO Codes. Monitoring. Wiring. Alarms θ. 0. °.

FANUC Robot series R-30iB Mate + Mate Plus Maintenance Manual

FANUC Robot series R-30iB Mate + Mate Plus Maintenance Manual

SRVO-348 DCS MCC OFF alarm a b. (Explanation) A command was issued to turn off the magnetic contactor

FANUC Robot series

FANUC Robot series

(89) SRVO-348 DCS MCC OFF alarm a b. (Explanation) A command was issued to turn off the magnetic contactor

DUAL CHECK SAFETY FUNCTION OPERATORS MANUAL

DUAL CHECK SAFETY FUNCTION OPERATORS MANUAL

"SRVO-337 DCS PRMCHK alarm" occurs if the current DCS parameters and the DCS parameters the alarm "SRVO-365 DCS FB_CMP alarm" occurs. ... SRVO-348 SERVO.

FANUC Robot series

FANUC Robot series

When one of the axes is out of the safe zone "SRVO-345 DCS outside of safe zone

FANUC Robot CRX-10iA CRX-10iA/L MECHANICAL UNIT

FANUC Robot CRX-10iA CRX-10iA/L MECHANICAL UNIT

Power-off stop of Robot is executed when collision detection alarm (SRVO-050) etc. occurs. Please try to avoid unnecessary power-off stops.

FANUC Robot series R-30iB/R-30iB Mate/R-30iB Plus/R-30iB Mate

FANUC Robot series R-30iB/R-30iB Mate/R-30iB Plus/R-30iB Mate

Unavailable robot model" or "SRVO-364 DCS PRMCRC alarm" occurs. the alarm "SRVO-365 DCS FB_CMP alarm" occurs. ... SRVO-348 DCS MCC OFF alarm i j.

FANUC Robot LR Mate 200iD ARC Mate 50iD MECHANICAL UNIT

FANUC Robot LR Mate 200iD ARC Mate 50iD MECHANICAL UNIT

348. 284. 332. Standard/7WP/7C. Stopping angle [deg] (rad). 82.1 (1.43) is so big that may cause occurrence of collision detect alarm (SRVO –050) etc.

FANUC Robot SAFETY HANDBOOK

FANUC Robot SAFETY HANDBOOK

The alarm "SRVO-199 Controlled stop" occurs along with a decelerated stop. Execution of the program is paused. - An alarm is generated and servo power is

FANUC Robot M-900iA -English-

FANUC Robot M-900iA -English-

M-900+A/600 : R 803. M-900+A/400L : R 980. 410. M-900+A/600 : 1285. M-900+A/400L : 2180300. 2832. 309. 19. 2979. R2832. 1000. 1. 120. 250. 827. 348.

OPERATORS MANUAL(Collaborative Robot Function)

OPERATORS MANUAL(Collaborative Robot Function)

If CONFIRM input is ON at the power-up “SRVO-473 DCS CLLB CC_EXTF alarm” might be SYST-348 Payload Monitor (Force) warning.

© FANUC CORPORATION, 2015

R-30+B/R-30+B Mate/R-30+B Plus/R-30+B Mate Plus/

R-30+B Mini Plus CONTROLLER

< Robot !OPERATOR'S MANUAL(Collaborative Robot Function)

B-83744EN/04

Original Instructions

Thank you

very much for purchasing FANUCCollaborative Robot.

Before using the Collaborative robot, be sure to read MECHANICAL UNIT OPERATOR'S MANUAL and understand the content. No part of this manual may be reproduced in any form. The appearance and specifications of this product are subject to change without notice. The products in this manual are controlled based on Japan's "ForeignExchange and

Foreign

Trade Law". The export from Japan may be subject to an export license by the government of Japan. Further, re-export to another country may be subject to the license of the government of the country from where the product is re -exported. Furthermore, the product may also be controlled by re-export regulations of the United States government. Should you wish to export or re-export these products, please contact FANUC for advice. In this manual, we endeavor to include all pertinent matters.There are, however, a very large number of operations that must not or cannot be performed, and if the manual contained them all, it would be enormous in volume.It is, therefore, requested to assume that any operations that are not explicitly described asbeing possible are "not possible".B-83744EN/04 SAFETY PRECAUTIONS

s -1SAFETY PRECAUTIONS

Before using the FANUC collaborative robot, be sure to read MECHANICAL UNIT OPERATOR'SMANUAL to become familiar with those contents.

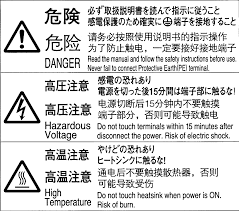

DEFINITION OF SAFETY NOTATIONS

To ensure the safety of users and prevent damage to the machine, this manual indicates each precaution

on safety with "" or "" according to its severity. Supplementary information is indicated by "". Please read each "", "" and "" before using the robots.Symbol Definitions

WARNING

Used if

hazard resulting in the death or serious injury of the user will be expected to occur if he or she fails to follow the approved procedure.CAUTION

Used if a hazard resulting in

the minor or moderate injury of the user, or equipment damage may be expected to occur if he or she fails to follow the approved procedure. NOTE Used if a supplementary explanation not related to any of WARNING and CAUTION is to be indicated. Check this manual thoroughly, and keep it handy for the future reference.B-83744EN/04 PREFACE

p-1PREFACE

The coexistence of human and robot will make a difference in production site from the point of view of

productivity, efficiency and so on. However, for coexistence of human and robot, adequate risk assessment for the whole the robot system is necessary to verify the human safety.Collaborative robot is befitted for this purpose, because the collaborative robot has the contact stop

function to stop when the external force exceeds the limit. This function is useful for design of the robot

system.The collaborative robot is certified to meet the requirements of International Standard ISO 10218-1 by an

internationally accredited certification body. The contact stop function is certified to meet the requirements of International ISO 138491 for Category

3, PL (Performance Level) d by an internationally accredited certification body.In order to design the collaborative robot system, it is necessary to understand the collaborative robot

function. This manual describes the collaborative robot function use.PREFACE B-83744EN/04

p-2 RELATED MANUALS

For the FANUC Robot series, the following manuals are available:R-30B,

R-30B Mate,

R-30B Plus,

R-30B Mate Plus

controller OPERATOR'S MANUALBasic Operation

B-83284EN

Alarm Code List

B-83284EN-1

Optional Function

B-83284EN-2

Dual Check

Safety Function

B-83184EN

Intended readers :

Operator, programmer, maintenance engineer, system designerTopics :

Robot functions, operations, programming, setup,

interfaces, alarms Use :Robot operation, teaching, system design

MAINTENANCE MANUAL

B-83525EN Intended readers :

Maintenance engineer, system designer

Topics :

Installation, start-up, connection, maintenance

Use :Installation, start-up, connection, maintenance

FANUC Robot

CR 4iA, CR 7iA, CR 7iA/L CR 14 iA/LMechanical unit

OPERATOR'S MANUAL

B-83774EN

Intended readers:

S ystem designer, Maintenance engineerTopics:

Installation, connection to controller, maintenance Use:Installation, start-up, connection, maintenance

FANUC Robot

CR 35iA

Mechanical unit OPERATOR'S MANUAL

B-83734EN Intended readers:

S ystem designer, Maintenance engineerTopics:

Installation, connection to controller, maintenance Use:Installation, start-up, connection, maintenance

FANUC Robot

CR 15 iAMechanical unit OPERATOR'S MANUAL

B-84054EN Intended readers:

S ystem designer, Maintenance engineerTopics:

Installation, connection to controller, maintenance Use:quotesdbs_dbs4.pdfusesText_7[PDF] ssl vpn certificate sonicwall

[PDF] ssl vpn fortigate

[PDF] st luke's hospital houston bertner cafe menu

[PDF] st malo coronavirus

[PDF] st thomas port guide

[PDF] staff eating breakfast at work

[PDF] stage culture hauts de france

[PDF] stages in language acquisition

[PDF] stages of bilingual language development

[PDF] stages of language acquisition pdf

[PDF] stages of language acquisition ppt

[PDF] stakeholder engagement

[PDF] stakeholder engagement pdf

[PDF] stakeholder engagement plan