FANUC Robot series R-30iB Mate + Mate Plus Maintenance Manual

FANUC Robot series R-30iB Mate + Mate Plus Maintenance Manual

SRVO-295 Amp com error. SRVO-297 Improper input power. SRVO-335 DCS OFFCHK alarm a b. SRVO-348 DCS MCC OFF alarm a

FANUC Robot series

FANUC Robot series

SRVO-266 through SRVO-275 and SRVO-370 through SRVO-385 are issued at the same (89) SRVO-348 DCS MCC OFF alarm a b. (Explanation) A command was issued to ...

OPERATORS MANUAL(Collaborative Robot Function)

OPERATORS MANUAL(Collaborative Robot Function)

SYST-348 Payload Monitor (Force) warning. • SYST-349 Payload Monitor (Moment) “SRVO-473 DCS CLLB CC_EXTF alarm” occurs. Verify followings. • Refer to A.2 ...

FANUC Robot series R-30iB/R-30iB Mate/R-30iB Plus/R-30iB Mate

FANUC Robot series R-30iB/R-30iB Mate/R-30iB Plus/R-30iB Mate

SRVO-339 DCS MISC alarm i j. SRVO-344 DCS GRP alarm(G i) j

HG-KN/HG-SN SERVO MOTOR INSTRUCTION MANUAL

HG-KN/HG-SN SERVO MOTOR INSTRUCTION MANUAL

Do not attempt to wire the servo amplifier and servo motor until they have been installed. 348 Victoria Road P.O. Box 11

1394-5.0-MAY00 1394 Digital AC Multi-Axis Motion Control System

1394-5.0-MAY00 1394 Digital AC Multi-Axis Motion Control System

servo drive system or an analog servo drive system. All 1394 systems [Jog Vel] parameter (348

mr-j4-_b_-ll servo amplifier instruction manual

mr-j4-_b_-ll servo amplifier instruction manual

POINT. When you connect the servo amplifier to a servo system controller servo 348 Victoria Road

OMNUC G5 SERIES AC SERVOMOTORS/SERVO DRIVES USERS

OMNUC G5 SERIES AC SERVOMOTORS/SERVO DRIVES USERS

SERVO DRIVE USER'S MANUAL. 3. Specifications. Model (R88M-). Item. Unit. 400 VAC ... 348. 5-11. 5-2 Speed Control. OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE ...

FANUC Series 0i-MODEL C/0i Mate-MODEL C MAINTENANCE

FANUC Series 0i-MODEL C/0i Mate-MODEL C MAINTENANCE

348 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.4.5.1 Starting the built–in ...

SureServo2™ AC Servo Systems User Manual

SureServo2™ AC Servo Systems User Manual

348. Chapter 7: Motion Control. Page 7–137. SureServo2 User Manual – 2nd Edition – 08/10/2023. Parameters. DI/DO Codes. Monitoring. Wiring. Alarms θ. 0. °.

FANUC Robot series R-30iB Mate + Mate Plus Maintenance Manual

FANUC Robot series R-30iB Mate + Mate Plus Maintenance Manual

SRVO-348 DCS MCC OFF alarm a b. (Explanation) A command was issued to turn off the magnetic contactor

FANUC Robot series

FANUC Robot series

(89) SRVO-348 DCS MCC OFF alarm a b. (Explanation) A command was issued to turn off the magnetic contactor

DUAL CHECK SAFETY FUNCTION OPERATORS MANUAL

DUAL CHECK SAFETY FUNCTION OPERATORS MANUAL

"SRVO-337 DCS PRMCHK alarm" occurs if the current DCS parameters and the DCS parameters the alarm "SRVO-365 DCS FB_CMP alarm" occurs. ... SRVO-348 SERVO.

FANUC Robot series

FANUC Robot series

When one of the axes is out of the safe zone "SRVO-345 DCS outside of safe zone

FANUC Robot CRX-10iA CRX-10iA/L MECHANICAL UNIT

FANUC Robot CRX-10iA CRX-10iA/L MECHANICAL UNIT

Power-off stop of Robot is executed when collision detection alarm (SRVO-050) etc. occurs. Please try to avoid unnecessary power-off stops.

FANUC Robot series R-30iB/R-30iB Mate/R-30iB Plus/R-30iB Mate

FANUC Robot series R-30iB/R-30iB Mate/R-30iB Plus/R-30iB Mate

Unavailable robot model" or "SRVO-364 DCS PRMCRC alarm" occurs. the alarm "SRVO-365 DCS FB_CMP alarm" occurs. ... SRVO-348 DCS MCC OFF alarm i j.

FANUC Robot LR Mate 200iD ARC Mate 50iD MECHANICAL UNIT

FANUC Robot LR Mate 200iD ARC Mate 50iD MECHANICAL UNIT

348. 284. 332. Standard/7WP/7C. Stopping angle [deg] (rad). 82.1 (1.43) is so big that may cause occurrence of collision detect alarm (SRVO –050) etc.

FANUC Robot SAFETY HANDBOOK

FANUC Robot SAFETY HANDBOOK

The alarm "SRVO-199 Controlled stop" occurs along with a decelerated stop. Execution of the program is paused. - An alarm is generated and servo power is

FANUC Robot M-900iA -English-

FANUC Robot M-900iA -English-

M-900+A/600 : R 803. M-900+A/400L : R 980. 410. M-900+A/600 : 1285. M-900+A/400L : 2180300. 2832. 309. 19. 2979. R2832. 1000. 1. 120. 250. 827. 348.

OPERATORS MANUAL(Collaborative Robot Function)

OPERATORS MANUAL(Collaborative Robot Function)

If CONFIRM input is ON at the power-up “SRVO-473 DCS CLLB CC_EXTF alarm” might be SYST-348 Payload Monitor (Force) warning.

© FANUC CORPORATION, 2012

Dual Check Safety Function

R-30+B/R-30+B Mate/R-30+B Plus/R-30+B Mate Plus/

R-30+B Compact Plus/R-30+B Mini Plus CONTROLLER

< Robot !OPERATOR'S MANUAL

B-83184EN/12

Original Instructions

Thank you

very much for purchasing FANUC Robot. Before using the Robot, be sure to read the "FANUC Robot series SAFETY HANDBOOK (B80687EN)" and understand the content.

No part of this manual may be reproduced in any form. All specifications and designs are subject to change without notice. The products in this manual are controlled based on Japan 's "Foreign Exchange andForeign Trade Law"

. The export from Japan may be subject to an export license by the government of Japan.Further, re-

export to another country may be subject to the license of the government of the country from where the product is re -exported. Furthermore, the product may also be controlled by re -export regulations of the United States government. Should you wish to export or re-export these products, please contact FANUC for advice. In this manual, we endeavor to include all pertinent matters.There are, however, a very large number of operations that must not or cannot be performed,and if the manual contained them all, it would be enormous in volume.It is, therefore, requested to assume that any operations that are not explicitly described asbeing possible are "not possible".B-83184EN/12 SAFETY PRECAUTIONS

s -1SAFETY PRECAUTIONS

This chapter describes the precautions which must be followed to enable the safe use of the robot. Before

using the robot, be sure to read this chapter thoroughly.For detailed functions of the robot operation, read the relevant operator's manual to understand fully its

specification.For the safety of the operator and the system, follow all safety precautions when operating a robot and its

peripheral equipment installed in a work cell. For safe use of FANUC robots, you must read and follow the instructions in FANUC Robot seriesSAFETY HANDBOOK (".

1 PERSONNEL

Personnel can be classified as follows.

Operator:

Turns the robot controller power ON/OFF

Starts the robot program from operator panel

Programmer or Teaching operator:

Operates the robot

Teaches the robot inside the safeguarded space

Maintenance technician:

Operates the robot

Teaches the robot inside the safeguarded space

Performs maintenance (repair, adjustment, replacement) The operator is not allowed to work in the safeguarded space. The programmer or teaching operator and maintenance technician are allowed to work in the safeguarded space. Works carried out in the safeguarded space include transportation, installation, teaching, adjustment, and maintenance. To work inside the safeguarded space, the person must be trained on proper robot operation.SAFETY PRECAUTIONS B-83184EN/12

s -2Table 1

(a) lists the work outside the safeguarded space. In this table, the symbol " means the work allowed to be carried out by the specified personnel.Table 1

(a) List of work outside the Safeguarded SpaceOperator

Programmer or

Teaching operator

Maintenance

technicianTurn power ON/OFF to Robot controller { {

Select operating mode (AUTO/T1/T2) { {

Select remote/local mode { {

Select robot program with teach pendant { {

Select robot program with external device { {

Start robot program with operator"s panel { { {

Start robot program with teach pendant { {

Reset alarm with operator"s panel { {

Reset alarm with teach pendant { {

Set data on teach pendant { {

Teaching with teach pendant { {

Emergency stop with operator"s panel { { {

Emergency stop with teach pendant { { {

Operator"s panel maintenance {

Teach pendant maintenance {

During robot operation, programming and maintenance, the operator, programmer, teaching operator and maintenance technician take care of their safety using at least the following safety protectors. Use clothes, uniform, overall adequate for the workSafety shoes

Helmet

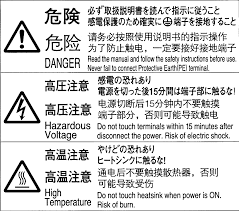

2 DEFINITION OF SAFETY NOTATIONS

To ensure the safety of users and prevent damage to the machine, this manual indicates each precaution

on safety with "" or "" according to its severity. Supplementary information is indicated by "". Read the contents of each ", "" and "" before using the robot.Symbol Definitions

WARNING

Used if

hazard resulting in the death or serious injury of the user will be expected to occur if he or she fails to follow the approved procedure.CAUTION

Used if a hazard resulting in the minor or moderate injury of the user, or equipment damage may be expected to occur if he or she fails to follow the approved procedure. NOTE Used if a supplementary explanation not related to any of WARNING and CAUTION is to be indicated.B-83184EN/12 TABLE OF CONTENTS

c-1TABLE OF CONTENTS

SAFETY PRECAUTIONS ............................................................................ s-11 OVERVIEW ............................................................................................. 1

1.1 DCS FUNCTION COMPONENTS ................................................................. 1 1.2 CAUTIONS AND LIMITATIONS .................................................................... 41.2.1 Hardware .................................................................................................................. 4

1.2.2 Software ................................................................................................................... 5

1.3 APPLY TO DCS PARAMETER ..................................................................... 6 1.4 DCS PARAMETER REPORT FILE ............................................................. 10 1.5 BACKUP / RESTORE DCS SETTING PARAMETER ................................. 10 1.6 INITIAL START, IMAGE RESTORE ............................................................ 12 1.7 STOPPING DISTANCE ............................................................................... 132 DCS MENU ............................................................................................ 14

2.1 DCS MENU COMPONENTS ....................................................................... 14 2.2DCS TOP MENU ......................................................................................... 16

2.3 DCS ROBOT SETUP MENU ....................................................................... 19 2.4 DCS MASTERING PARAMETER MENU .................................................... 21 2.5 DCS CODE NUMBER ................................................................................. 222.5.1 DCS Code Number Setup Menu ............................................................................ 23

2.6 DCS SIGNATURE NUMBER ....................................................................... 242.6.1 DCS Signature Number Menu ............................................................................... 24

2.6.2 DCS Signature Annunciation Menu ....................................................................... 25

2.6.2.1 DCS signature change management utility setup ............................................... 26

2.6.2.2 DCS signature change management utility operation ........................................ 27

2.6.3 DCS Signature Number Output .............................................................................. 27

2.6.4 Code by Password Function ................................................................................... 28

3 LIMITING A ROBOT WORKSPACE ..................................................... 29

3.1OVERVIEW ................................................................................................. 29

3.2 LIMITING A ROBOT WORKSPACE BY CARTESIAN POSITION CHECK . 30 3.3 ROBOT STOP POSITION PREDICTION .................................................... 33 3.4 SETUP OF USER MODEL .......................................................................... 34 3.54D GRAPHICS DCS DISPLAY .................................................................... 38

3.6 RECOVERY FROM ALARM ........................................................................ 404 SWITCHING THE WORKSPACE ......................................................... 41

TABLE OF CONTENTS B-83184EN/12

c-2 4.1OVERVIEW ................................................................................................. 41

4.2 SETUP OF USER MODEL .......................................................................... 42 4.3 CHECKING IF THERE IS AN OPERATOR ON A SAFE MAT..................... 45 4.4 SETUP OF CARTESIAN POSITION CHECK .............................................. 464.4.1 Setup of No.1 Zone ................................................................................................ 47

4.4.2 Setup of No.2 Zone ................................................................................................ 51

4.4.3 Setup of No.3 Zone ................................................................................................ 55

5 CHECKING IF AUXILIARY AXES ARE STATIONARY ....................... 59

5.1OVERVIEW ................................................................................................. 59

5.2 SETUP STOP CHECK FOR AUXILIARY AXIS 1 ........................................ 60 5.3 SETUP OF POSITION CHECK FOR AUXILIARY AXIS 1 ........................... 63 5.4 SETUP OF STOP CHECK FOR AUXILIARY AXES 2 AND 3 ..................... 66 5.5 LIMITING THE MOTION RANGE OF A TURNTABLE ................................ 71 5.6 SETTING UP THE ROBOT WORKSPACE ................................................. 736 SET A SLOWDOWN ZONE .................................................................. 76

6.1OVERVIEW ................................................................................................. 76

6.2 SETUP OF TOOL MODEL .......................................................................... 77 6.3 SETUP OF CARTESIAN POSITION CHECK .............................................. 826.3.1 Setup of No.1 Zone ................................................................................................ 83

6.3.2 Setup of No.2 Zone ................................................................................................ 85

6.3.3 Setup of No.3 Zone ................................................................................................ 88

7 POSITION / SPEED CHECK FUNCTION ............................................. 92

7.1 COMPONENTS OF POSITION / SPEED CHECK FUNCTION ................... 93 7.2 JOINT POSITION CHECK FUNCTION ....................................................... 937.2.1 Stop Position Prediction ......................................................................................... 95

7.2.2 DCS Joint Position Check List Menu ..................................................................... 96

7.2.3 DCS Joint Position Check Detail Menu ................................................................. 97

7.3 JOINT SPEED CHECK FUNCTION ............................................................ 987.3.1 DCS Joint Speed Check List Menu ........................................................................ 99

7.3.2 DCS Joint Speed Check Detail Menu .................................................................. 100

7.4 ZONE CHECK FUNCTION (CARTESIAN POSITION CHECK FUNCTION)................................................................................................................... 102

quotesdbs_dbs4.pdfusesText_7[PDF] ssl vpn certificate sonicwall

[PDF] ssl vpn fortigate

[PDF] st luke's hospital houston bertner cafe menu

[PDF] st malo coronavirus

[PDF] st thomas port guide

[PDF] staff eating breakfast at work

[PDF] stage culture hauts de france

[PDF] stages in language acquisition

[PDF] stages of bilingual language development

[PDF] stages of language acquisition pdf

[PDF] stages of language acquisition ppt

[PDF] stakeholder engagement

[PDF] stakeholder engagement pdf

[PDF] stakeholder engagement plan