bar psi kPa/MPa Kg/cm2 Mbar

Page 1. bar psi. kPa/MPa. Kg/cm2. Mbar. 0.025. 0.363. 2.5 kPa. 0.025. 25. 0.04. 0.58 5. 72.516. 500 kPa. 5.098. 5000. 6. 87.020. 600 kPa. 6.117. 6000.

pdf pressure card

Untitled

(a) the specific volume at T = 240°C p = 1.25 MPa

ThermoHmwk Soln

OEM Perspective on Cryogenic H2 Storage

15 kg/min. (3 MW). CGH2. 40 g/L. 69-65 g/L. 1

compressed hydrogen brunner

ME 24-221 THERMODYNAMICS I Solutions to Assignment 11

December 1 2000. J. Murthy. 11.4 A steam power plant operating in an ideal Rankine cycle has a high pressure of 5. MPa and a low pressure of 15 kPa.

as sol

Table 1. Saturation (Temperature)

Table 1. Saturation (Temperature) (continued). 5 t °C p

NISTIR Tab

ME 24-221 THERMODYNAMICS I Solutions to extra problems in

Nov 9 2000 1. 2 s = C. 8.29 A mass and atmosphere loaded piston/cylinder contains 2 kg of water at 5 MPa

extra sol

KNOWN: Water is the working fluid in an ideal Rankine cycle. The

5. Saturated liquid exits the open feedwater heater and saturated liquid exits State 5: Ps= P2 = 1 MPa (10 bar)

HW

Thermo 1 (MEP 261) Thermodynamics An Engineering Approach

5–7 Air enters a nozzle steadily at 2.21 kg/m until the density in the tank rises to 7.20 kg/m ... steadily at 1 MPa and 500°C with a mass flow rate.

sheet solution

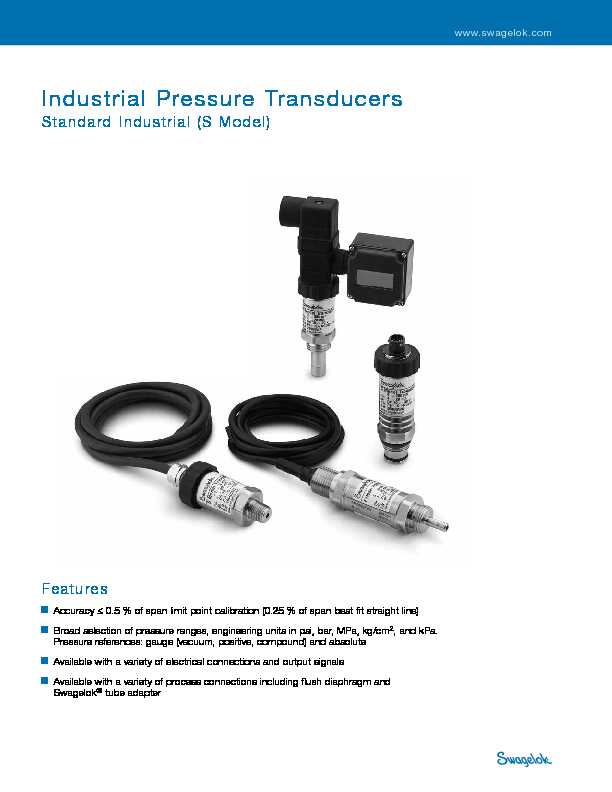

Industrial Pressure Transducers Standard Industrial S Model

equivalent (200 bar 20 MPa

ms

AREN 2110 SOLUTIONS FALL 2006 HOMEWORK ASSIGNMENTS

5-45 A number of brass balls are to be quenched in a water bath at a specified rate. kJ/kg. 3240.9. /kg m. 0.02975. C. 450. MPa. 10. 1. 3. 1. 1. 1.

SOLUTIONS HOMEWORKS F

Industrial Pressure Transducers 1067

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

CHECK & RELIEF

VALVES

NEEDLE &

METERING

VALVES

REGULATORS

& FILTERSINSTRUMENT

MANIFOLD

SYSTEMS

TRANSDUCERS

REFERENCES

MEDIUM- HIGH-

PRESSURE

TUBEFITTINGS

2 , and kPa. Pressure references: gauge (vacuum, positive, compound) and absoluteSwagelok

tube adapterIndustrial Pressure Transducers

Standard Industrial (S Model)

www.swagelok.com 1068TUBE

FITTINGS

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

NEEDLE &

METERING

VALVES

CHECK & RELIEF

VALVES

REGULATORS

& FILTERSINSTRUMENT

MANIFOLD

SYSTEMS

TRANSDUCERS

REFERENCES

MEDIUM- HIGH-

PRESSURE

Contents

Features .................................. 1068

Performance Data .......................... 1068

Materials of Construction .................... 1068 Calibration ................................ 1068 Model Selection Guide ...................... 1069Transducer S Model: S ........ 1070

Pressure Range Designators .................. 1072Dimensions ............................... 1074

Options ................................... 1076

Accessories

Attachable Indicator Display ................ 1076Cooling Elements ......................... 1078

Weld Adapters ........................... 1078

Cables and Connectors .................... 1078

Swagelok industrial

pressure transducers provide electronic monitoring of system pressure for general industrial applications, including hazardous locations.Stainless steel

construction with robust, compact design that resists pressure spikes, shock, and vibration Variety of pressure ranges, process connections, electrical connections, and output signals for system versatilityThin lm and piezoresistive sensor technology for

repeatability, reliability, and stability Temperature-compensated to ensure accuracy and long- term stability when exposed to temperature variations Available in ush diaphragm version for use with viscous uids and slurries Wiring protection against reverse polarity and short circuit on the instrument sideComponentS ModelE Model

Wetted

(25 bar [362 psi, 2.5 MPa,25.5 kg/cm

2 , 2500 kPa] and lower pressure range)316 SS

Internal diaphragm

(over 25 bar [362 psi, 2.5 MPa,25.5 kg/cm

2 , 2500 kPa] pressure range)AISI S13800Elgiloy

Process connection,

flush diaphragm316 Ti

Flush diaphragm, O-ringBuna N

wettedTransducer body316 SS

Flush diaphragm

internal fluid, piezoresistive sensor internal fluidSynthetic oil

Accuracy 0.5 % LPC (0.25 % BFSL), including

nonlinearity, hysteresis, zero-point and full-scale error, measured in accordance with IEC 61298-2 0.1 % of spanStability

02 % of span per year

1 ms with internal diaphragm connection; 10 ms with flush diaphragm connectionResistance

( for field case models) in accordance with IEC 600682 27

(mechanical shock)

Resistance

( for field case models) in accordance with IEC 600682 6 (vibration under resonance)

Coefficients

(TC) inCompensated

Temperature

RangePressure ranges equal to or less than 0

25bar (3 6 psi, 0 025

MPa, 0

25 kg/cm

2 25kPa): 0.4 % of span per 18°F (10°C) change on zero point.

Pressure ranges higher than 0

25 bar (3.6 psi,

0 025MPa, 0

25Industrial Pressure Transducers 1067

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

CHECK & RELIEF

VALVES

NEEDLE &

METERING

VALVES

REGULATORS

& FILTERSINSTRUMENT

MANIFOLD

SYSTEMS

TRANSDUCERS

REFERENCES

MEDIUM- HIGH-

PRESSURE

TUBEFITTINGS

2 , and kPa. Pressure references: gauge (vacuum, positive, compound) and absoluteSwagelok

tube adapterIndustrial Pressure Transducers

Standard Industrial (S Model)

www.swagelok.com 1068TUBE

FITTINGS

PIPE, WELD,

VCR, VCO

FITTINGS

STANDARD

TUBING

MODULAR

SYSTEMD

HOSE /

FLEXIBLE

TUBING

BELLOWS,

DIAPHRAGM

VALVES

BALL & PLUG

VALVES

NEEDLE &

METERING

VALVES

CHECK & RELIEF

VALVES

REGULATORS

& FILTERSINSTRUMENT

MANIFOLD

SYSTEMS

TRANSDUCERS

REFERENCES

MEDIUM- HIGH-

PRESSURE

Contents

Features .................................. 1068

Performance Data .......................... 1068

Materials of Construction .................... 1068 Calibration ................................ 1068 Model Selection Guide ...................... 1069Transducer S Model: S ........ 1070

Pressure Range Designators .................. 1072Dimensions ............................... 1074

Options ................................... 1076

Accessories

Attachable Indicator Display ................ 1076Cooling Elements ......................... 1078

Weld Adapters ........................... 1078

Cables and Connectors .................... 1078

Swagelok industrial

pressure transducers provide electronic monitoring of system pressure for general industrial applications, including hazardous locations.Stainless steel

construction with robust, compact design that resists pressure spikes, shock, and vibration Variety of pressure ranges, process connections, electrical connections, and output signals for system versatilityThin lm and piezoresistive sensor technology for

repeatability, reliability, and stability Temperature-compensated to ensure accuracy and long- term stability when exposed to temperature variations Available in ush diaphragm version for use with viscous uids and slurries Wiring protection against reverse polarity and short circuit on the instrument sideComponentS ModelE Model

Wetted

(25 bar [362 psi, 2.5 MPa,25.5 kg/cm

2 , 2500 kPa] and lower pressure range)316 SS

Internal diaphragm

(over 25 bar [362 psi, 2.5 MPa,25.5 kg/cm

2 , 2500 kPa] pressure range)AISI S13800Elgiloy

Process connection,

flush diaphragm316 Ti

Flush diaphragm, O-ringBuna N

wettedTransducer body316 SS

Flush diaphragm

internal fluid, piezoresistive sensor internal fluidSynthetic oil

Accuracy 0.5 % LPC (0.25 % BFSL), including

nonlinearity, hysteresis, zero-point and full-scale error, measured in accordance with IEC 61298-2 0.1 % of spanStability

02 % of span per year

1 ms with internal diaphragm connection; 10 ms with flush diaphragm connectionResistance

( for field case models) in accordance with IEC 600682 27

(mechanical shock)

Resistance

( for field case models) in accordance with IEC 600682 6 (vibration under resonance)

Coefficients

(TC) inCompensated

Temperature

RangePressure ranges equal to or less than 0

25bar (3 6 psi, 0 025

MPa, 0

25 kg/cm

2 25kPa): 0.4 % of span per 18°F (10°C) change on zero point.