TECHNIQUES DE RECHERCHE DEMPLOI POUR LES JEUNES

TECHNIQUES DE RECHERCHE DEMPLOI POUR LES JEUNES

978-92-2-132209-2 (web pdf) 24. Accueil et introduction. Objectifs. 33. Module n°1 : Ouverture de l' ... Le guide méthodologique sur les Techniques.

HP StorageWorks 1/8 Tape Autoloader User and Service Guide

HP StorageWorks 1/8 Tape Autoloader User and Service Guide

Native: 24 MB/s (86 GB/hr.) Compressed: 48 MB/s (172 GB/hr.) (2:1 compression). Characteristic. Specification. Maximum storage capacity. 8 data cartridges.

Prise en charge de lhypertension artérielle de ladulte

Prise en charge de lhypertension artérielle de ladulte

Cette fiche mémo a été élaborée selon la méthode décrite dans le guide 1. Contexte. L'hypertension artérielle (HTA) est définie par consensus et selon ...

Guide explicatif du Protocole de Nagoya sur laccès et le partage

Guide explicatif du Protocole de Nagoya sur laccès et le partage

24 Voir la Décision X/1 Accès aux ressources génétiques et partage juste et équitable des avantages découlant de leur utilisation

Repair Procedures for Pressure-Sensitive Trim Using 3M

Repair Procedures for Pressure-Sensitive Trim Using 3M

1. Use a piece of monofilament line and make several knots spaced about. 1 inch apart. to 24 hours with the tape side down in the cleaner.

Product Instructions Sponge-Stick Eponge Sponge-Stick Sponge

Product Instructions Sponge-Stick Eponge Sponge-Stick Sponge

Retain the safety instructions for future reference. Service (1-800-328-1671 in the U.S.) or your official 3M Food Safety ... Sac de 1524 cm x 0.

SOLVE: politiques de sécurité et santé au travail Intégrer la

SOLVE: politiques de sécurité et santé au travail Intégrer la

ISBN: 978-92-2-224279-5; 978-92-2-224280-1 (web pdf); 978-92-2-224281-8 (CD-ROM) Le guide du formateur: il comprend 12 modules dont la fonction est de ...

M2N-SLI - Deluxe

M2N-SLI - Deluxe

No part of this manual including the products and software described in it

VisualDSP++ 5.0 Users Guide

VisualDSP++ 5.0 Users Guide

Purpose of This Manual . 1-24. Creating Files to Add to Your Project . ... VisualDSP++ and processor manuals in Portable Documentation Format (PDF).

Dynamic Weighing

Dynamic Weighing

24 bits. Formated resolution. 500 000 pts. -. ±500 000 pts. ±500 000 pts. ±500 000 pts. ±500 000 pts. Max. measuring speed. 6.25 1600 meas./s.

ADHÉSION AU CNAS 2023

ADHÉSION AU CNAS 2023

Par ailleurs vous y trouverez le guide de l’adhésion précisant les modalités de gestion de l’adhésion Pour une communication optimale entre le CNAS l’adhérent et les bénéficiaires le délégué élu le délégué agent et le correspondant ont chacun un rôle clé

This technical update outlines the recommended procedures for repairing pressure-sensitive body side moldings

(BSMs) and trim attached with both black 3MAutomotive

Acrylic Plus Tapes and gray 3M

Automotive

Acrylic

Attachment

Tapes. The following procedures offer specifics on removal and re-application ofBSMs and trim. Supersedes Technical Update dated January 2006Remove the Body Side Molding (BSM) or Trim from the Vehicle

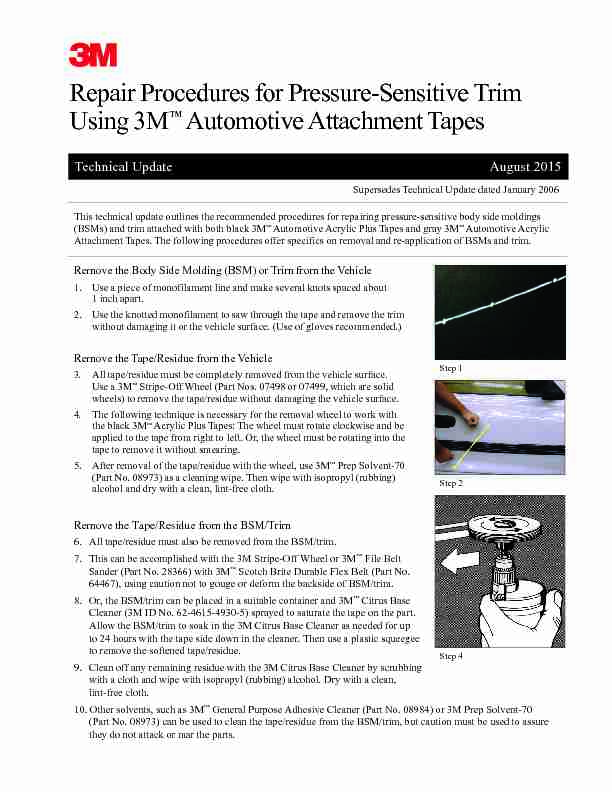

1 .Use a piece of monofilament line and make several knots spaced about 1 inch apart. 2 .Use the knotted monofilament to saw through the tape and remove the trim without damaging it or the vehicle surface. (Use of gloves recommended.)August 2015etadpU lacinhceTRemove

the Tape/Residue from the Vehicle3.All tape/residue must be completely removed from the vehicle surface.

Use a 3M Stripe-Off Wheel (Part Nos. 07498 or 07499, which are solid wheels) to remove the tape/residue without damaging the vehicle surface.4.The following technique is necessary for the removal wheel to work with

the black 3M™Acrylic

PlusTapes:The wheel must rotate clockwise and be

applied to the tape from right to left.Or, the wheel must be rotating into the

tape to remove it without smearing.5.After removal of the tape/residue with the wheel, use 3M

PrepSolvent-70

(Part No. 08973) as a cleaning wipe. Then wipe with isopropyl (rubbing) alcohol and dry with a clean, lint-free cloth.Remove the Tape/Residue from the BSM/Trim6. All tape/residue must also be removed from the BSM/trim.

7. This can be accomplished with the 3M Stripe-Off Wheel or 3M

File Belt

Sander (Part No. 28366) with 3M

Scotch Brite Durable Flex Belt (Part No.

64467), using caution not to gouge or deform the backside of BSM/trim.

8. Or, the BSM/trim can be placed in a suitable container and 3M

Citrus Base

Cleaner (3M ID No. 62-4615-4930-5) sprayed to saturate the tape on the part. Allow the BSM/trim to soak in the 3M Citrus Base Cleaner as needed for u p to 24 hours with the tape side down in the cleaner. Then use a plastic s queegee to remove the softened tape/residue.9. Clean off any remaining residue with the 3M Citrus Base Cleaner by scrub

bing with a cloth and wipe with isopropyl (rubbing) alcohol. Dry with a cle an, lint-free cloth.10. Other solvents, such as 3M™

General Purpose Adhesive Cleaner (Part No. 08984) or 3M Prep Solvent- 70(Part No. 08973) can be used to clean the tape/residue from the BSM/tr im, but caution must be used to assure they do not attack or mar the parts. Re pair Procedures for Pressure-Sensitive Trim Us ing 3M Au tom oti ve Attachment TapesStep 1 Step 2 Step 4 Repair Procedures for Pressure-Sensitive Trim Page 2 Apply 3M

Automotive

Acrylic Plus Tape to BSM/Trim

14 .Apply the 3MAutomotive

Attachment Tape to the BSM/trim, being careful

not to entrap air between the part and tape. 15 .Use a hard rubber roller or firm hand pressure to securely bond the tape to theBSM/trim.

16 .Keep all contaminants (fingers, gloves, cloths, etc.) off the adhesive surface of the tape while applying it. Store the BSM/trim with the new tape applied in a clean area until it is re-applied to the vehicle. Re -A pply the BSM/Trim to the Vehicle 17 .Apply BSM/trim to a clean, dry vehicle (as previously described). 18 .Application temperatures below 60ºF should be avoided. It is important that the vehiclenot have any condensation on it (i.e., a cold vehicle moved into a warm shop). If necessary, warm the vehicle

surface with a heat gun to obtain the recommended vehicle surface application temperature of 60ºF to 110ºF.19.Apply BSM/trim with a rolling motion and with firm pressure to assure maximum tape contact with the vehicle,

resulting in greater adhesion.20.Use a hard rubber hand roller to roll the BSM/trim on the vehicle. Apply firm pressure while rolling to ensure

complete adhesive wet-out and a good bond.21.Check the edges of the BSM/trim to verify good tape adhesion. Re-roll the BSM/trim with more pressure if necessary.

Important

Precautions and Recommendations

DO NOT...Touch or contaminate the exposed adhesive surface of the tape. Let the tape sit around with the adhesive surface exposed. Apply the new tape over the old tape or tape residue. Use an adhesion promoter on the painted surface of the vehicle. DO ...Use recommended 3M products for repair of all automotive BSMs and trim.Read and follow safety precautions on the product label and MSDS for each product used in this procedure.

ApplyAdhesion Promoter to BSM/Trim

11.Prime the BSM/trim with 3M

Automotive

Adhesion Promoter (Part

No .06396) in the areas the tape will be applied. 12 .Be careful not to drip or spill the primer on the BSM/trim face as it may craze or damage the finish. 13 .The use of the 3MAutomotive

Adhesion Promoter (Part No. 06396) will

assure an optimum bond due to the widespread use of low surface energy plastics by the automotive industry. Step 14 Step 15 Step 11Automotive

Aftermarket Division

3MCenter, Building 223-6N-01

St.Paul, MN 55144-1000

www.3M.com/automotive3M 2015. All rights reserved.

3M is a trademark of 3M Company.75-346

9-7558-6 Technical Information: The technical information, recommendations and other statements containe

d in this document are based upon tests or experience that3M believes are reliable, but the accuracy or completeness of such infor

mation is not guaranteed.Product Use:

Many factors beyond 3M's control and uniquely within user's knowledge and control can affect the use and performance of a 3M product in a

particular application. Given the variety of factors that can affect the use and performance of a 3M product, user is solely responsible

for evaluating the 3M product and determining whether it is fit for a particular purpose and s uitable for user's method of application.Warranty, Limited Remedy, and Disclaimer:

Unless an additional warranty is specifically stated on the applicable3M product packaging or product

literature, 3M warrants that each 3M product meets the applicable 3M pro duct specification at the time 3M ships the product. 3M MAKES NO OTHERWARRANTIES OR CONDITIONS, EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, ANY IMPLIED WARRANTY OR CONDITION OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR ANY IMPLIED WARRANTY OR CONDITION ARISING OUT OF A COURSE

OF DEALING, CUSTOM OR USAGE OF TRADE. If the 3M product does not conform to this warranty, then the sole and exclusive remedy is, at 3M's

option, replacement of the 3M product or refund of the purchase price.Limitation of Liability: Except where prohibited by law, 3M will not be liable for any loss or damage arising from the 3M produ

ct, whether direct, indirect, special, incidental or consequential, regardless of the legal theory ass erted, including warranty, contract, negligence or strict liability.quotesdbs_dbs28.pdfusesText_34[PDF] CNC 2015 - Ecole des Sciences de l 'Information

[PDF] Résultats d 'admissibilté CNC 2015

[PDF] Comptable - l 'organisation nationale des comptables agrees

[PDF] Correction CNC, partie informatique

[PDF] Correction CNC, partie informatique

[PDF] CONCOURS DE L 'INTERNAT EN PHARMACIE - CNCI

[PDF] Le Directeur Gnral

[PDF] Loi 09-08 - CNDP

[PDF] Conduite en douane des colis postaux L acheminement d

[PDF] Untitled - CNDP

[PDF] CNEC CNEC - Institut National Du Cancer

[PDF] français - Cned

[PDF] au service de toutes les reussites 2017 - Cned

[PDF] Calendrier_Etablissements ? l 'Etranger_2016-2017